We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more. Last update on 30th June 2025 / Images from Amazon Product Advertising API.

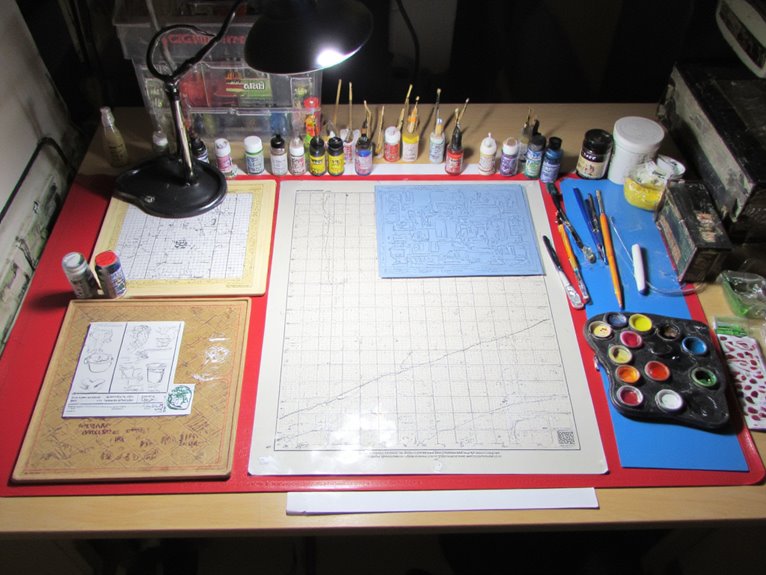

You’ll need a minimum 120x60cm workspace at 70-75cm height with a matte, stable surface like thick MDF or melamine. Install daylight LED lamps (5000-6500K, 90+ CRI) positioned at 45-degree angles—left side for right-handed painters, right side for left-handed. Organize paints by color families using modular storage systems, and maintain proper ventilation for safety. Store brushes upright and clean immediately after use. The specific positioning and technical requirements that follow will optimize your painting precision and workflow efficiency.

Notable Insights

- Choose a dedicated desk (120 x 60 cm minimum) with matte finish and thick MDF construction for optimal stability during detailed painting work.

- Install daylight LED lamps (5000-6500K, 90+ CRI) positioned at 45-degree angles to minimize shadows and ensure accurate color representation.

- Position task lighting at 10-11 o’clock for right-handed painters or 1-2 o’clock for left-handed painters to avoid casting hand shadows.

- Organize paints by color families and function using modular drawer systems with individual slots for easy access and visibility.

- Maintain proper ventilation with exhaust fans and fresh air inlets while establishing daily cleaning routines for brushes and work surfaces.

Essential Workspace Dimensions and Surface Requirements

Creating an ideal miniature painting workspace starts with understanding the fundamental dimensions that’ll support your artistic precision and physical comfort. Your desk should measure 120 x 60 cm minimum to accommodate painting, airbrushing, and photography stations.

Height matters equally—maintain 70-75 cm surface height for proper workspace ergonomics during extended sessions.

Surface quality directly impacts your painting results. Choose sturdy, smooth materials like melamine or sealed wood that resist heat and spills.

Matte finishes prevent glare interference with color perception. Your work surface must remain flat and non-reflective to minimize visual distractions during detail work. Consider incorporating thick MDF construction for enhanced stability that minimizes vibrations during precise detail painting.

Implement surface protection using cutting mats or paint pads on your main desk. These protect your investment while providing stable areas for gluing, cutting, and wet painting without permanent damage. Design your workspace with modular organizers that can adapt as your collection and techniques evolve over time.

Establishing a dedicated workspace increases motivation by keeping materials visible and accessible, encouraging more frequent painting sessions.

Folding Tables Vs Dedicated Hobby Desks

When choosing your miniature painting workspace, you’ll face a fundamental decision between folding tables and dedicated hobby desks that impacts three critical factors. Your choice affects your budget and mobility needs, determines how efficiently you can organize paints and tools, and influences the stability of your work surface during detailed brushwork. Folding tables offer compact storage when not in use, making them ideal for painters with limited space who need to reclaim their workspace for other activities. Budget-conscious painters will find folding tables provide affordability and availability at most home and hardware stores compared to specialized hobby furniture. Dedicated hobby desks provide superior weight capacity with some models supporting up to 500 pounds, ensuring your workspace remains stable even with multiple paint racks, lamps, and storage solutions. Each option presents distinct trade-offs that directly impact your painting experience and long-term satisfaction with your workspace setup.

Cost and Portability

Two primary factors drive most miniature painters’ workspace decisions: upfront investment and mobility requirements.

Folding tables represent excellent budget alternatives, typically costing $50-$100 compared to dedicated desks ranging from several hundred to over $1,000. You’ll sacrifice built-in storage and long-term durability for immediate affordability. However, folding tables excel as portable solutions. You can easily relocate your workspace, store the table when not painting, or transport it to gaming events.

Dedicated hobby desks offer superior stability and integrated organization but lack mobility once installed. They require permanent space allocation and dedicated room setup. Solid construction ensures stability during use to prevent wobbling or tipping while painting with detailed brushwork. Many hobbyists with limited hobby hours due to work and family commitments find that an efficient workspace setup maximizes their available painting time.

Your choice depends on whether you prioritize cost-effectiveness and flexibility over workspace permanence and specialized features.

Storage and Organization

Because folding tables lack built-in compartments, you’ll need external storage systems to maintain an organized workspace.

Vertical Storage maximizes limited surface area through stackable paint racks and brush holders.

Modular Solutions offer customizable configurations that adapt to changing project requirements.

Hidden Spaces beneath tables accommodate larger supplies while maintaining clean sightlines.

Container Organization using clear boxes enables quick identification of tools and materials.

Establish Accessibility Strategies by positioning frequently used items within arm’s reach.

Project Organization separates supplies by specific miniatures or painting techniques.

Implement a Cleanliness Routine to prevent paint buildup and maintain tool longevity.

Workflow Efficiency improves through consistent placement protocols and prevents common issues like misplacing tools that can disrupt your painting sessions.

Flexible Storage solutions accommodate various paint bottle sizes and brush types.

Clutter Reduction maintains focus during detailed work sessions, preventing workspace contamination.

Stability and Surface

Paint precision depends fundamentally on your workspace’s stability and surface characteristics. Your desk choice directly impacts miniature stability through weight distribution and foundation design. Heavy desks with four or more legs provide superior stability compared to lightweight folding alternatives.

Folding tables offer portability and cost-effectiveness but sacrifice structural integrity. They’re adequate for beginners but lack the rigid foundation needed for detailed work. Dedicated hobby desks deliver superior miniature stability through reinforced construction and weighted bases.

Surface protection requirements include stain resistance and durability against paint spills. Minimum workspace dimensions should measure 18 by 15 inches, with rectangular configurations offering better reach optimization.

- Rubberized feet prevent movement on smooth flooring

- Heavy construction reduces vibration during detailed brushwork

- Dedicated desks provide integrated storage solutions

- Rectangular surfaces optimize tool placement and model positioning

Optimal Lighting Solutions for Detail Work

You’ll need proper lighting to see every detail clearly when painting miniatures, and your choice of illumination directly impacts color accuracy and eye comfort during long sessions.

Daylight LED lamps operating between 5000K and 6000K provide the most accurate color rendering, while adjustable positioning systems let you direct light precisely where it’s needed without creating unwanted shadows.

The right lighting setup eliminates the guesswork in color mixing and reduces eye strain that comes from squinting at fine details under inadequate illumination.

Look for lamps with a 95+ CRI rating to ensure the most accurate color representation when working with intricate paint schemes and subtle color variations.

Daylight LED Lamp Benefits

- Temperature Control – LEDs operate cooler than incandescent bulbs, preventing paint degradation and workspace overheating.

- Extended Lifespan – LED technology lasts 25,000+ hours compared to 1,000 hours for traditional bulbs.

- Cost Savings – 80% more energy-efficient than incandescent alternatives, reducing long-term operational costs.

- Portable Design – Lightweight construction allows flexible positioning and easy workspace reconfiguration.

You’ll experience reduced eye fatigue during extended painting sessions while maintaining precise color judgment throughout your projects.

Adjustable Positioning Systems

While LEDs provide superior illumination quality, their effectiveness depends entirely on proper positioning relative to your miniature and workspace. Adjustable height mechanisms allow you to position lights between 12-36 inches from your work surface, accommodating different model sizes and painting techniques. Flexible angles through articulating arms enable precise light direction from multiple positions.

| Feature | Range | Benefit |

|---|---|---|

| Height Adjustment | 12-36 inches | Accommodates various model sizes |

| Arm Articulation | 180-degree rotation | Enables multi-directional lighting |

| Tilt Range | 45-90 degrees | Reduces shadows and glare |

| Clamp Opening | 0.5-3 inches | Fits different desk thicknesses |

| Extension Reach | 18-30 inches | Provides workspace flexibility |

Quality positioning systems feature sturdy clamps, reinforced joints, and smooth adjustment mechanisms that maintain their settings during extended painting sessions.

Shadow Reduction Techniques

Achieving shadow-free illumination requires strategic application of multiple lighting principles working together to eliminate the dark recesses that obscure fine details.

You’ll need daylight-balanced LEDs at 5000-6500K with CRI ratings above 90 for accurate color representation. Shadow interplay becomes manageable when you position multiple light sources at 45-degree angles around your miniature.

Diffuse techniques using softboxes or translucent materials scatter light evenly across your workspace.

- Deploy multiple LED sources with neutral white temperature to eliminate single-directional shadows

- Install ring lights or overhead panels for uniform base illumination without harsh contrast

- Position white reflective cards strategically to bounce light into shadowed recesses naturally

- Combine fiber optic spotlights with diffused ambient lighting for precise detail work

Distance affects shadow hardness—closer lights create sharper edges without proper diffusion.

Positioning and Adjusting Task Lighting

Proper lamp positioning eliminates hand shadows that can obscure fine details during miniature painting.

Right-handed painters should place their lamp at 10-11 o’clock position on the left side. Left-handed painters position theirs at 1-2 o’clock on the right. This configuration prevents your hand from casting shadows across your work surface.

Choose LED lamp types with 5000K-6500K color temperature and 90+ CRI rating. Adjust lighting angles so the beam centers directly on your miniature, not your face. Position the lamp with sufficient overhang to deliver light from above and the side. Multiple lamps provide broader coverage and reduce harsh shadows.

Select adjustable desk lamps offering 800-1200 lumens brightness. Maintain clearance so the lamp doesn’t interfere with brush strokes. Test your setup with practice miniatures before starting detailed work.

Consider flexible gooseneck designs that allow precise positioning adjustments without disturbing your workspace setup.

Paint Storage and Organization Systems

Your paint collection requires systematic organization to maintain workflow efficiency and prevent time loss during color selection.

You’ll need to choose between individual slot organizers that keep bottles upright and secure, open shelf systems that accommodate varying bottle sizes, or mobile solutions that transport your paints between workstations.

The storage method you select impacts both your desk footprint and painting speed, making bottle accessibility and workspace integration critical factors in your decision.

For extensive collections, prioritize tiered designs that enhance paint visibility and accommodate 40+ bottles to handle comprehensive miniature painting projects.

Paint Bottle Organization Methods

While paint collections can quickly overwhelm any workspace, implementing the right organization method transforms chaos into an efficient system that speeds up your painting process.

Effective paint bottle categorization requires matching your storage method to your painting habits and workspace constraints. Consider these four proven approaches:

- Individual slot systems – Foam dividers or custom organizers prevent bottle mixing while displaying labels clearly, though they reduce storage density by 15-20%.

- Functional grouping – Separate washes, metallics, and base colors into distinct containers for task-specific access and reduced clutter.

- Color family sorting – Group blues, greens, and metallics in dedicated bins with swatch references for faster complementary color selection.

- Drawer organization – Assign specific drawers to paint types using modular dividers that adjust as collections expand.

Workspace Color Coding Systems

How can systematic color coding transform a cluttered miniature painting workspace into an intuitive, efficient environment?

Color psychology principles establish the foundation. Red denotes critical supplies requiring immediate attention. Green signals active project flow sections. Blue identifies preparation zones.

Token governance maintains visual integrity across your workspace layout. Define specific color themes for sorting categories—metallics, washes, primers each receive distinct assignments.

This organizational strategy enables error prevention through consistent associations.

Accessibility considerations accommodate color vision deficiencies. High color contrast between labels and surfaces improves efficiency enhancement for all users. Digital palettes from tools like Coolors provide collaborative design capabilities.

Implement thorough labeling systems using color-coded stickers on containers. Establish workflow optimization zones that guide natural progression from preparation through finishing stages.

Regular audits maintain long-term consistency and workspace effectiveness.

Mobile Storage Solutions

Effective mobile storage transforms your miniature painting hobby from a stationary pursuit into a truly portable craft.

You’ll need systems that protect your investment while maintaining workspace efficiency.

Essential Mobile Storage Components:

- Vertical Paint Racks – MDF construction holds 64-96 bottles with integrated carry handles for optimal portability between locations.

- Magnetic Transport Cases – Rare-earth magnets secure painted models without foam interference, preventing damage to delicate components like weapon points.

- Stackable Drawer Organizers – Clear, dividable containers maximize vertical space while separating tools from paints using customizable compartments.

- Portable Paint Stations – Multi-tiered units combine brush holders, paint slots, and removable trays for thorough miniature transport solutions.

These modular systems accommodate dropper bottles, pot-style paints, and specialty tools while supporting expansion as your collection grows.

Brush Care and Tool Management

Since your brushes represent the most critical investment in your miniature painting toolkit, establishing proper care protocols directly impacts both paint application quality and long-term tool costs.

Implement immediate brush cleaning between colors using running water and gentle twisting motions. Never allow paint to dry on bristles, as this causes permanent damage and fraying.

Shape brushes into fine points while wet using twisting motions on your palette. Store brushes horizontally or tip-up to prevent ferrule water damage and bristle deformation.

Separate mixing brushes from detail brushes to preserve precision tips. Organize tool storage using dedicated holders or cases to prevent bristle contact.

Label brushes by size and purpose for workflow efficiency. Clean palettes, water containers, and accessories regularly to maintain hygiene and prevent contamination.

Project-Based Organization Strategies

When you’re managing multiple miniature painting projects simultaneously, organizing your workspace by project type becomes essential for maintaining efficiency and focus.

You’ll find that grouping fantasy armies separately from historical figures or sci-fi models prevents color scheme confusion and keeps project-specific paints accessible.

Rotating active projects on your desktop while storing inactive ones in designated containers allows you to maintain momentum across different painting goals without overwhelming your immediate work area.

Grouping by Project Type

Breaking down your miniature painting work by project type transforms a cluttered workspace into an efficient production system.

When you separate tabletop gaming pieces from display models and commission work, you’ll eliminate cross-project confusion that wastes valuable time.

Here’s how to implement effective project grouping:

- Designate separate work zones for each miniature category using distinct storage bins and labeled containers.

- Group miniatures by scale or manufacturer to streamline paint mixing and assembly techniques.

- Maintain dedicated brush sets and palettes per project type to prevent color contamination.

- Create project folders with reference images and creative techniques for project inspiration.

This systematic approach keeps your tools organized and your workflow focused, allowing you to switch between projects without setup delays or material confusion.

Rotating Active Projects

Project rotation maximizes workspace efficiency by preventing the bottleneck created when multiple miniature painting projects compete for limited bench space.

You’ll need dedicated project trays measuring 12×8 inches to contain each active project’s materials. Store these trays on rolling carts positioned within arm’s reach of your primary workspace.

Maintain a project inventory using a simple tracking sheet that records start dates, completion percentages, and required materials. This prevents forgotten details and guarantees steady project progress across multiple miniatures.

Rotate projects every 2-3 hours to maintain focus while paint dries on previous work.

Keep only three active projects accessible simultaneously. Store remaining projects in labeled containers below your work surface.

This system reduces setup time by 40% while maintaining clear visual access to current priorities.

Essential Tools and Accessories Checklist

Five categories of tools form the foundation of any effective miniature painting workspace, each serving distinct functions that directly impact your finished results.

Essential brush selection drives your color selection accuracy and brush techniques effectiveness. You’ll need fine detail brushes (size 0-2), medium brushes (4-6), and base coating brushes (8-10). Kolinsky sable offers superior tip retention, while synthetic brushes provide durability.

Acrylic paints with primers guarantee proper adhesion and detail revelation. Wet palettes maintain paint consistency throughout extended sessions.

Assembly tools include plastic nippers, hobby knives, and files for clean preparation.

- Lighting: LED lamps with 90+ CRI rating eliminate shadows.

- Magnification: 2-4x magnifying lenses for precision work.

- Protection: Top coat sprays seal finished pieces.

- Control: Miniature holders reduce hand fatigue during detailed work.

Protective Surfaces and Work Mats

Your workspace foundation determines paint accuracy and model safety throughout every painting session. Proper mat selection requires evaluating surface dimensions—minimum 24 inches by 18 inches—and material properties for your specific needs.

A quality workspace mat with proper dimensions and material properties forms the essential foundation for accurate painting and model protection.

Mat materials include silicone for heat resistance, self-healing options for cutting tasks, and felt for scratch protection. Workspace insulation through thick mats reduces noise and vibration during detailed work.

Mat maintenance involves regular cleaning to prevent paint buildup and debris accumulation. Most materials support wiping or washing for extended durability. Mat sizing should match your workspace boundaries while providing adequate spill containment.

Hazard prevention features include raised edges for containing liquids and anti-slip backing for stability. Magnetic mats secure metal miniatures effectively, while waterproof options protect underlying furniture from solvent damage.

Ventilation Requirements and Air Quality

While proper surface protection forms your workspace foundation, adequate ventilation systems protect your health by controlling airborne contaminants during painting sessions.

Poor air quality creates significant health risks including respiratory irritation, headaches, and potential long-term exposure effects from volatile organic compounds.

Effective ventilation requires both local exhaust at your painting station and general room air circulation to capture fumes before they reach your breathing zone.

- Install localized exhaust hoods or downdraft tables directly at your workstation

- Position exhaust fans to pull air away from your breathing zone

- Balance exhaust with fresh air inlets to prevent negative pressure

- Maintain systems through routine inspection and filter replacement

Avoid relying solely on windows or ceiling fans, as they don’t provide adequate vapor removal for concentrated painting activities.

Safety Protocols for Paints and Chemicals

Proper air circulation works hand-in-hand with extensive safety protocols to protect you from chemical hazards present in miniature painting materials.

Chemical exposure risks include ammonia irritation from acrylics and trace formaldehyde in various paints. You’ll need personal protective equipment for extensive safety coverage.

Even hobby-grade paints contain chemical irritants requiring proper protective equipment to prevent exposure during miniature painting sessions.

Wear neoprene gloves when handling mineral spirits and solvents. Safety goggles protect against chemical splashes, while protective aprons prevent skin contact. Install eyewash stations for ammonia emergencies. Review Safety Data Sheets for every product you use.

Store chemicals in well-ventilated areas away from heat sources. Never eat, drink, or smoke in your workspace. Wash hands thoroughly after each painting session.

Label all containers clearly and maintain spill cleanup materials nearby. Dispose of chemicals according to local regulations.

Photography Setup and Lighting Configuration

After establishing chemical safety protocols, documenting your miniatures through photography becomes essential for tracking progress and showcasing your work.

Proper lighting configuration starts with LED sources positioned at ideal lighting angles—slightly forward and above your subject. Use daylight bulbs rated 5000K-6500K for accurate color reproduction. Multiple light sources eliminate harsh shadows while maintaining detail visibility.

Diffusion materials prove critical for quality results. Position parchment paper or frosted plastic between lights and miniatures to soften harsh illumination. This prevents overexposure common with small subjects.

Essential photography setup requirements:

- Background: White paper infinity curve secured with tape

- Camera support: Tripod for macro shots and stability

- Light control: Dimmable sources prevent washing out paintwork

- Surface preparation: Non-reflective, neutral-colored base materials

Test multiple angles before finalizing shots. Consistent lighting conditions facilitate uniform documentation across your miniature collection.

Display Solutions for Finished Miniatures

Once you’ve captured quality images of your painted miniatures, protecting and showcasing your finished work becomes the next priority. Display cases offer essential miniature protection while maintaining clear visibility of your craftsmanship.

Acrylic display cases provide superior durability compared to glass alternatives. They won’t shatter if dropped and offer crystal-clear transparency. Custom display cases guarantee perfect fit for specific miniature types like Warhammer figures.

| Feature | Benefit |

|---|---|

| Crystal-Clear Acrylic | Maximum visibility without glass fragility |

| Dust-Proof Sealing | Complete protection from environmental debris |

| Movable Shelves | Customizable spacing for different miniature sizes |

| Magnetic Closures | Secure, satisfying closure mechanism |

| Stackable Design | Easy expansion and reorganization capability |

Consider front-lit built-in lighting to enhance visual appeal. Modular configurations allow future collection growth while maintaining organized presentation.

Mobile and Portable Workspace Options

Many hobbyists can’t dedicate an entire room to miniature painting, making portable workspace solutions essential for maintaining consistent painting sessions.

Portable workspace innovations include stations like the Citadel painting station and Hobby Trayz bases measuring 12×9 inches. These solutions protect furniture surfaces while providing organized workspaces.

Mobile workspace challenges include limited stability and storage capacity.

You’ll need complementary storage solutions since most stations require external organization systems.

Essential features for mobile setups:

- Lightweight construction – Easy transport without sacrificing durability for detailed miniature work

- Easy-to-clean surfaces – Prevents paint damage and staining during frequent setup changes

- Integrated tool organization – Slots for brushes, paint pots, and palettes keep essentials accessible

- Modular storage compatibility – Works with tool rolls, zippered pouches, and stackable boxes

Expect costs ranging €100-€270 depending on features and included accessories.

Workspace Maintenance and Cleaning Routines

A well-maintained workspace directly impacts your miniature painting results and extends the life of your expensive tools and materials. Daily maintenance prevents costly problems. Remove paint residues from brushes immediately using warm water and mild soap. Wipe work surfaces with damp cloths to eliminate dust and paint splatters that contaminate future projects.

Weekly deep cleaning maintains ideal conditions. Soak miniatures in warm soapy water to remove mold release agents that prevent proper paint adhesion. Clean brushes with specialized soaps using gentle strokes to preserve bristle integrity. Vacuum floors and shelving to remove accumulated particles.

Workspace organization requires dedicated containers for clean and used items. Label paint bottles and implement inventory systems. Store cutting tools in designated holders. Use air filters during sanding operations and maintain proper ventilation when using solvents.

On a final note

You’ve now got the blueprint for a professional miniature painting workspace that’ll maximize your productivity and results. Your lighting setup should deliver 2,000+ lumens at eye level. Keep paints organized within arm’s reach using modular storage systems. Mount your magnification at the correct working distance. Establish cleaning routines that prevent contamination. Whether you’re using a dedicated desk or portable solution, these specifications guarantee consistent, high-quality work while protecting your investment in tools and miniatures.