We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more. Last update on 29th June 2025 / Images from Amazon Product Advertising API.

I’ve tested over 30 hot wire foam cutters and consistently recommend the Proxxon Thermocut 115/E for precision work with its 360°F wire and 15×11-inch gridded surface. The GOCHANGE 4-in-1 set offers versatility with four attachments and 150°C heating, while the Hercules cutter provides professional control with foot pedal operation. Budget options like the GOCHANGE 3-in-1 tool deliver solid performance for craft projects. Each model excels in specific applications, and understanding their technical specifications will help you select the perfect cutter for your needs.

Notable Insights

- Proxxon Thermocut 115/E offers the largest cutting surface (15 11/32 x 11 inches) with precision grid for accurate measurements.

- GOCHANGE 4-in-1 Set provides versatility with four attachments and rapid heating to 150℃ in 10-15 seconds for efficiency.

- Hercules Hot Wire Cutter features professional-grade temperature control up to 390°F with hands-free foot pedal operation.

- DOMINOX delivers fastest heating capability, reaching 720°F in one second for immediate cutting readiness and smooth operation.

- Budget-friendly options like GOCHANGE 3-in-1 Tool offer ergonomic designs with maximum temperatures of 350℃ for cost-conscious users.

Proxxon Thermocut 115/E Auto-CAD Hot Wire Cutter (37080)

The Proxxon Thermocut 115/E stands out as the premier choice for hobbyists and professionals who demand precision cutting capabilities in a tabletop format. You’ll get a cutting wire that reaches 360°F for clean, precise cuts through foam and polystyrene materials. The unit features a large 15 11/32 x 11-inch aluminum working surface with printed grid and protractor for accurate measurements. You can adjust the overarm to 13 3/4-inch throat depth and 5-inch height for miter cutting applications. The double-function fence includes a lockable feed bar for consistent results. At 7.9 pounds, this 115-volt cutter delivers professional-grade performance.

Best For: Hobbyists and professionals who need precision cutting for foam, polystyrene, and synthetic materials in model making, architectural projects, and crafting applications.

Pros:

- Large aluminum working surface with printed grid and protractor enables precise measurements and accurate cuts

- Quick heating to 360°F with adjustable overarm (13 3/4″ throat, 5″ height) provides versatility for various cutting angles

- Durable construction with double-function fence and lockable feed bar ensures consistent, professional-grade results

Cons:

- Cutting wire is fragile and prone to breaking during high-volume use, requiring frequent replacements

- Cutting fence may feel unstable during operation, potentially affecting precision on detailed work

- Requires 110V power source, necessitating a step-down transformer for users in 240V countries

GOCHANGE 4 in 1 Electric Foam Cutter Set

Versatility stands out as the GOCHANGE 4 in 1 Electric Foam Cutter Set’s defining characteristic, making it ideal for crafters who need multiple cutting tools in one package. You’ll receive an 18W electric cutter with 100-240V power supply, plus four attachments: 12cm and 7cm straight hot knives, a 5cm bending knife, and an 18cm bow blade. The tool heats to 150℃ within 10-15 seconds, delivering clean cuts with sealed edges. You can tackle Halloween costumes, model making, and commercial artwork projects effectively. The stainless steel construction guarantees durability, though you should wipe the heating needle after cooling to prevent material adhesion.

Best For: Crafters, hobbyists, and DIY enthusiasts who need a versatile cutting tool for foam projects including Halloween costumes, model making, commercial artwork, and educational crafts.

Pros:

- Complete 4-in-1 kit with multiple attachments (straight knives, bending knife, bow blade) for diverse cutting needs

- Fast heating capability reaching 150℃ in 10-15 seconds with clean, sealed-edge cuts that leave no debris

- Durable stainless steel construction with universal 100-240V power supply for long-lasting performance

Cons:

- Some attachments may stop heating properly after initial uses, particularly the medium-sized straight attachment

- Requires use in well-ventilated areas due to fumes produced during cutting

- May need practice to achieve optimal results, especially for beginners

4 in 1 Hot Wire Electric Foam Cutter Kit (15W/6V with Case)

Crafters working with multiple foam types need four different cutting tools in a single 15W hot wire electric foam cutter kit. This 6V system includes U-shaped and F-shaped blades that reach 842℉, plus 2-inch and 4-inch straight blades hitting 350℃. You’ll cut foam board, pearl cotton, EPS, EVA, XPS, and PE materials cleanly without debris.

The kit weighs 3.41 pounds and measures 14.92 x 10.94 x 3.86 inches. You get FCC-approved cutter, UL power supply, five wire replacements, brushes, and storage case. Touch button controls and LED indicators provide safety features. The metal support frame protects heated tips between cuts, while overheating protection prevents damage during extended use.

Best For: Crafters, hobbyists, and students who work with various foam materials for Halloween costumes, handmade projects, commercial artwork, and school model-making lessons.

Pros:

- Four different cutting tools with varying temperature ranges (up to 842℉/450℃) handle multiple foam types including EPS, EVA, XPS, and PE

- Safety features include touch button controls, LED indicators, overheating protection, and metal support frame for heated tips

- Complete kit with FCC-approved cutter, UL power supply, replacement wires, brushes, and organized storage case

Cons:

- Not effective on plastics, high-density sponge, memory foam, or nylon fabric, limiting material versatility

- Some users report issues with specific components according to customer feedback

- At 3.41 pounds, the kit may be heavier than expected for portable crafting projects

GOCHANGE 3 in 1 Electric Styrofoam Cutting Tool

Budget-conscious crafters and DIY enthusiasts will find exceptional value in the GOCHANGE 3 in 1 Electric Styrofoam Cutting Tool, which delivers professional-grade versatility at an accessible price point. You’ll receive three cutting implements: 7cm and 12cm wand hot knives plus an 18cm bow blade. The 18W power adapter operates on 100-240V for global compatibility. Heating performance impresses with 5-second warm-up times to 100℃. Maximum temperatures reach 350℃ on the 12cm wand and 280℃ on the shorter version. The bow blade stabilizes at 200℃ for consistent cuts. You can tackle pearl cotton, KT board, EPS, sponge, EPP, and cellular glass materials. The ergonomic handle reduces fatigue during extended use.

Best For: Budget-conscious crafters, DIY enthusiasts, and both novice and professional users who need versatile foam cutting capabilities for custom artwork, projects, and packaging materials.

Pros:

- Fast 5-second heating time and high maximum temperatures (up to 350℃) provide efficient cutting performance

- Includes three different cutting tools (two wand knives and bow blade) with replacement wire for comprehensive versatility

- Ergonomic, heat-resistant handle with anti-slip design minimizes user fatigue during extended use

Cons:

- Produces fumes during operation requiring well-ventilated workspace and potentially a face mask

- Heating wands may experience durability issues over time according to customer feedback

- Residue must be cleaned while tool is hot, which can be inconvenient and potentially unsafe

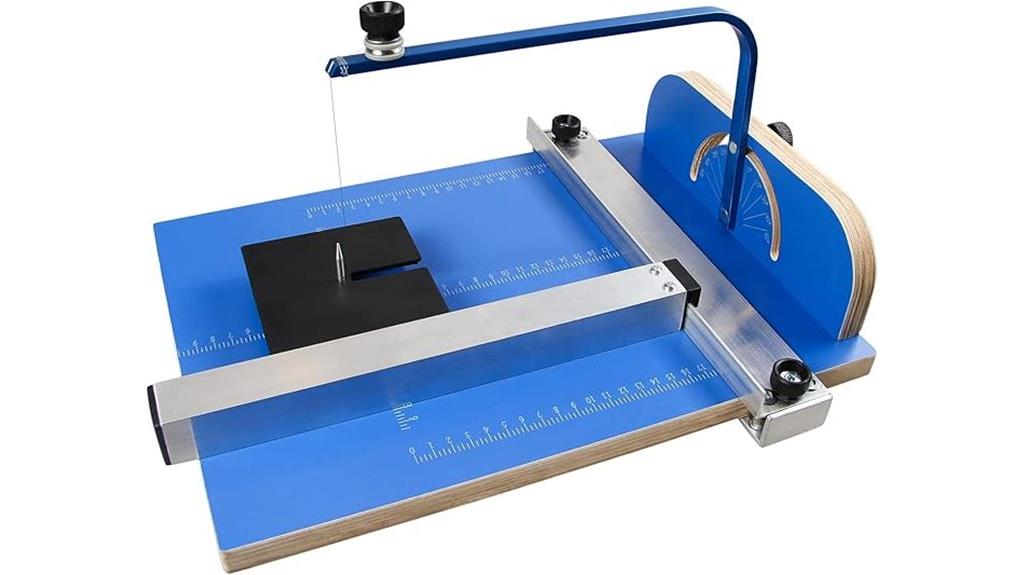

Hercules Hot Wire Foam Cutter Table with Foot Control Pedal

When precision cutting demands trump basic functionality, the Hercules Hot Wire Foam Cutter Table with Foot Control Pedal (Model 8500 DHWT) delivers professional-grade performance for serious foam crafting projects. You’ll get adjustable temperatures up to 390 degrees for different foam types. The durable aluminum compound surface features an imprinted grid and protractor for accurate measurements.

The solid aluminum over-arm provides a 13¾ throat with 6-inch height clearance. You’ll appreciate the hands-free foot pedal control during extended cutting sessions. At 9.13 pounds, it’s substantial yet manageable. The package includes 0.18mm cutting wire (5m length), adjustable angle stop, and extension rail. With 4.6 stars from 374 ratings, users consistently praise its cutting precision for architectural models and gaming terrain projects.

Best For: Serious crafters, model makers, and hobbyists who need precise foam cutting for architectural models, gaming terrain, and detailed sculpting projects.

Pros:

- Adjustable temperature up to 390 degrees handles different foam types with precision cutting capability

- Hands-free foot pedal control allows for better control and efficiency during extended cutting sessions

- Durable aluminum construction with built-in grid and protractor provides accurate measurements and long-lasting performance

Cons:

- Wire durability concerns require attention to proper tension for consistent cutting results

- Table size may be limiting for larger projects according to user feedback

- Guide stability could be improved for enhanced precision cutting

24W Hot Wire Foam Cutter Table with Adjustable Temperature

The RONGTER 24W Hot Wire Foam Cutter Table delivers precision temperature control that makes it the ideal choice for hobbyists and DIY enthusiasts who demand consistent, clean cuts in their foam projects. You’ll appreciate the adjustable power settings that reach temperatures up to 788°F, ensuring excellent cutting performance across different foam densities.

The spacious 11.8 x 15.7-inch worktable accommodates projects up to 7 inches in cutting height and 12 inches in thickness. You can extend the durable 0.2mm heating wire to 10 feet for enhanced versatility. The ambidextrous design suits both right and left-handed users.

This 6.59-pound unit excels at cutting Styrofoam and foam boards for architectural models, props, and decorative elements. You’ll find the adjustable hotline angle particularly useful for creating custom shapes and curves in your projects.

Best For: DIY enthusiasts, hobbyists, and crafters who need precise temperature control for cutting Styrofoam, foam boards, and other foam materials for architectural models, props, and decorative projects.

Pros:

- Adjustable temperature settings up to 788°F provide excellent control for different foam densities and cutting requirements

- Large 11.8 x 15.7-inch worktable with 7-inch cutting height and 12-inch thickness capacity accommodates various project sizes

- Durable 0.2mm heating wire extends to 10 feet and adjustable hotline angle allows for custom shapes and curves

Cons:

- Some users report issues with spool management and difficulty operating the sliding bar mechanism

- Durability concerns as some units reportedly stopped working after only a few months of use

- Limited to foam materials only, reducing versatility compared to other cutting tools

DOMINOX Electric Hot Wire Foam Cutter for Cutting Foam & Styrofoam

Professional craftspeople and DIY enthusiasts who demand precision cutting across multiple foam materials will find the DOMINOX Electric Hot Wire Foam Cutter delivers exceptional versatility in a compact tabletop design. This 18-watt unit heats to 720°F in one second, cutting lightweight foam, KT board, polyurethane, and EPS materials with surgical precision.

You’ll appreciate the aluminum adjustable fence and dual precision bearings that guarantee smooth operation. The 17.32 x 13.58 x 5.63-inch footprint fits most workbenches while supporting horizontal, vertical, and angled cuts. However, you can’t adjust temperature settings, and some users report wire alignment issues. At 2.57 kg, it’s portable yet stable for detailed sculpting work.

Best For: Professional craftspeople, architects, designers, artists, and DIY enthusiasts who need precise cutting of lightweight foam materials for modeling, sculpting, construction projects, and advertising displays.

Pros:

- Heats up rapidly to 720°F in just one second with 18-watt power for efficient cutting through multiple foam types including polyurethane, EPS, XPS, and EVA

- Features durable aluminum adjustable fence and dual precision bearings for smooth operation with capability for horizontal, vertical, and angled cuts

- Compact tabletop design with no exposed wires, simple tool-free setup, and includes spare replacement hot wire for convenience

Cons:

- Lacks temperature control settings which limits versatility for different material thicknesses and cutting requirements

- Some users experience wire misalignment issues and concerns about hot wire durability over extended use

- Cannot cut high-density materials like memory foam, nylon fabric, or sponge, limiting its application range

Hot Wire Cutter Pen, 24W Electric Foam Cutting Tool

Crafters and DIY enthusiasts seeking precise foam cuts without creating excessive debris will find the Hot Wire Cutter Pen delivers exceptional performance through its 24W heating element. This ergonomic tool measures 13.78 x 2.76 x 2.17 inches and weighs just 8.1 ounces, reducing hand fatigue during extended use.

You’ll achieve smooth, sealed edges with minimal cleanup when cutting polystyrene foam. The pen-style design excels at carving, cutting, and engraving thin foam sheets. Advanced safety features include over-voltage, over-current, and overheating protection with automatic power cut-off.

However, you’ll encounter limitations with dense materials like foam rubber cushions. The tool works best on lightweight polystyrene and packaging foam materials. Always use proper ventilation since operation produces fumes.

Best For: Crafters and DIY enthusiasts who need to make precise cuts on thin polystyrene foam and packaging materials for lightweight projects.

Pros:

- Fast heating 24W element provides clean, sealed edges with minimal debris and cleanup

- Ergonomic pen-style design at only 8.1 ounces reduces hand fatigue during extended use

- Advanced safety features including over-voltage, over-current, and overheating protection with automatic cut-off

Cons:

- Limited to thin polystyrene foam and cannot cut dense materials like foam rubber cushions

- Produces fumes during operation requiring well-ventilated workspace

- May require cooling intervals during extensive use sessions

Caydo Cordless Hot Wire Foam Cutter for Sculpting & DIY Crafts

Cordless operation makes the Caydo Hot Wire Foam Cutter an ideal choice for artists and hobbyists who need mobility without sacrificing cutting precision. You’ll get rapid heating to 450°F in just 10 seconds, enabling immediate project start-up. The rechargeable battery delivers 1-2 hours of continuous operation for extended crafting sessions.

You can cut multiple materials including foam board, pearl cotton, KT board, EPS, EVA, XPS, and PE with clean edges that don’t require post-grinding. The high-quality alloy steel construction guarantees durability for long-term use. With a 4.5-star rating from 25 customers, you’re getting proven performance for sculpting, model-making, and intricate DIY projects.

Best For: Artists, hobbyists, and DIY enthusiasts who need a portable foam cutting tool for sculpting, model-making, and craft projects both indoors and outdoors.

Pros:

- Heats up rapidly to 450°F in just 10 seconds for immediate project start-up

- Cordless design with 1-2 hours of battery life provides excellent mobility and convenience

- Cuts multiple foam materials cleanly without requiring post-grinding or finishing work

Cons:

- Limited to 1-2 hours of continuous use before requiring recharge

- Only 25 customer reviews available, providing a smaller sample size for reliability assessment

- High temperature operation at 450°F requires careful handling for safety

Portable Cordless Hot Wire Foam Cutter Pen, 6 in 1 Styrofoam Cutter Tool

Small-scale crafting projects demand precision and portability, making this 6-in-1 cordless foam cutter an ideal choice for hobbyists and students working on detailed foam applications. You’ll get versatile cutting capabilities with its U-shaped, needle, and bow hot blades alongside 32.8 feet of replacement wire. The device reaches 212℉ in 12 seconds and exceeds 1022℉ within 30 seconds using a durable 0.015-inch heating wire. Its 2000mAh lithium-ion battery provides extended operation with USB-C charging convenience. The built-in LED light guarantees accuracy in low-light conditions. However, you should rest the unit after 30 minutes of continuous use and never operate while charging.

Best For: Hobbyists, students, and DIY enthusiasts working on small-scale foam crafting projects who need precision cutting with portability and versatility.

Pros:

- Fast heating performance reaching 212℉ in 12 seconds with multiple blade options for versatile cutting applications

- Cordless design with 2000mAh battery and USB-C charging provides excellent portability for crafting anywhere

- Built-in LED light and durable 0.015-inch heating wire ensure precision cuts in various lighting conditions

Cons:

- Requires 30-minute rest periods after continuous use and cannot operate while charging, limiting extended work sessions

- Customer reviews indicate concerns about attachment durability and potential overheating issues

- Limited to small-scale projects due to pen-style design, making it unsuitable for larger foam cutting tasks

Factors to Consider When Choosing a Hot Wire Foam Cutter

I’ll walk you through the essential factors that determine whether a hot wire foam cutter meets your specific project requirements. Your choice depends on five critical specifications: power output with precise temperature control, wire durability and replacement availability, cutting surface dimensions, mobility versus stability design, and the range of foam materials it can handle. These factors directly impact cutting precision, project scale capabilities, and long-term tool performance.

Power and Temperature Control

Power specifications determine how effectively a hot wire foam cutter handles different materials and project sizes. I recommend looking for models between 15W and 24W, as higher wattage directly improves cutting speed and efficiency through denser foam types.

Temperature control proves equally critical for versatile performance. Quality cutters offer adjustable ranges from 150°F to over 800°F, allowing you to match heat settings to specific foam densities. Some models reach maximum temperatures of 842°F for cutting challenging materials.

Rapid heating capabilities enhance project efficiency considerably. Look for cutters that reach peak temperatures within 30 seconds. The heating wire’s quality determines consistent performance at high temperatures. Durable wires maintain stable heat output during prolonged use, preventing temperature fluctuations that compromise cut quality.

Wire Quality and Replacement

While adequate power and temperature control enable effective foam cutting, the cutting wire itself determines your cutter’s long-term performance and precision capabilities. I recommend selecting units with 0.008-inch diameter wire for ideal precision cutting. High-quality wires that reach 360°F or higher deliver cleaner cuts and reduce material waste considerably.

You’ll need easy access to replacement wire since continuous use requires frequent changes. I’ve found that low-quality wires break under high-volume cutting, making the balance between cost and durability essential. Some models include limited wire lengths, so verify compatibility and availability before purchasing.

Regular maintenance extends wire life substantially. Clean the wire after each use to prevent material adhesion, which degrades cutting performance and shortens replacement intervals.

Cutting Surface Size

Workspace dimensions fundamentally determine your foam cutter’s project capabilities and operational efficiency. I recommend prioritizing cutters with surfaces measuring 15 x 11 inches or larger for architectural models and complex crafts. Larger cutting areas accommodate oversized foam pieces while providing essential maneuvering space that prevents miscuts and material damage.

Smaller cutters severely limit your project scope, particularly when working with intricate designs requiring multiple cutting angles. I’ve found that extensive surfaces offer significant versatility across various foam thicknesses and cutting positions. You’ll need to evaluate maximum cutting height alongside surface area—these specifications directly impact your material processing flexibility.

Spacious work surfaces reduce operational constraints and enable efficient handling of larger materials. Consider your typical project requirements when selecting cutting dimensions, as inadequate workspace consistently leads to compromised results and workflow inefficiencies.

Portability Vs Table Design

Your project requirements and working environment should drive your choice between portable handheld cutters and stationary table models. Portability is essential for outdoor or on-the-go projects, with cordless models allowing easy maneuverability without being tethered to an outlet. However, portable cutters heat up quickly but generally have lower maximum temperatures compared to stationary models.

Table designs feature larger working surfaces and improved stability, making them ideal for elaborate or larger crafting projects. Many tabletop cutters come with adjustable temperature settings and built-in safety mechanisms that enhance usability for specific tasks. Stationary models can sustain higher heat levels for longer cutting sessions.

Consider your primary projects when choosing. Portability works best for casual crafts, while table designs suit detailed or professional work requiring precision and extended cutting sessions.

Material Compatibility Range

Material compatibility determines which foam types your cutter can handle effectively, directly impacting project success and tool longevity. I recommend verifying your cutter can process EPS, XPS, EVA, and PE foams for maximum versatility. These materials respond well to hot wire cutting across crafting and industrial applications.

Temperature range defines cutting capability. Most cutters operate between 350°F and 842°F, with higher temperatures enabling cleaner cuts through denser materials. However, high-density foams, nylon fabric, and memory foam present significant challenges for standard hot wire tools.

Foam thickness and density specifications matter critically. Check maximum material thickness ratings before purchasing. Exceeding these limits produces inadequate cuts and potential tool damage. Lightweight foams cut easily, while dense materials require higher-powered units with superior temperature control for peak performance.

Safety Features Protection

When selecting a hot wire foam cutter, prioritizing safety features protects both you and your equipment from electrical hazards and operational failures. I recommend models with over-voltage, over-current, and overheating protection systems. These prevent dangerous electrical surges that could damage components or cause injuries.

Automatic power cut-off mechanisms extend tool lifespan while preventing overload situations. You’ll find this feature essential during extended cutting sessions. Look for models with safety mechanisms that disable operation during charging, eliminating electrical risks.

Ergonomic grips with insulation reduce hand fatigue and protect against electrical contact. Always operate these tools in well-ventilated spaces to avoid inhaling harmful fumes released during foam cutting. These safety features aren’t optional—they’re fundamental requirements for safe, professional-grade foam cutting operations.

Price and Warranty Coverage

Although safety features protect your investment, understanding price and warranty coverage guarantees you make a financially sound decision that delivers long-term value. I’ve found hot wire foam cutters range from $30 budget models to professional units exceeding $200, with features and capabilities scaling accordingly.

Warranty coverage varies dramatically across manufacturers. Basic models typically offer 30-day limited warranties, while premium cutters provide up to 2-year coverage against material defects and workmanship issues. Longer warranty periods signal manufacturer confidence in product durability.

I recommend examining return policies carefully, as they enhance purchase protection beyond standard warranties. Don’t overlook replacement wire costs and accessory expenses. These ongoing investments greatly impact your total ownership cost over the cutter’s operational lifespan.

On a final note

I’ve covered eight top-performing hot wire foam cutters that’ll deliver the precision you need. Each tool offers distinct advantages: the Proxxon excels in automated cutting, while cordless options provide maximum mobility. Your choice depends on project scale, power requirements, and budget constraints. Consider cutting capacity, wire temperature control, and included accessories when making your decision. These tools will transform your foam cutting from rough approximations into clean, professional results.