We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more. Last update on 29th June 2025 / Images from Amazon Product Advertising API.

I’ve tested dozens of hot wire cutters to identify the most precise tools for foam and plastic cutting. The Proxxon Thermocut 115/E leads with 4.7/5 ratings and exceptional accuracy for detailed work, while the TapeTech 36V offers cordless portability for professionals. The 4-in-1 Electric Kit provides versatile cutting tips for hobbyists, and Calcor’s C3M table delivers rapid 3-second heating with multi-angle capabilities. Power ranges from 15W for basic tasks to 250W for commercial applications, with temperatures reaching 932°F for sustained performance across various synthetic materials.

Notable Insights

- The Proxxon Thermocut 115/E offers exceptional precision with a 4.7/5 rating, ideal for detailed architectural models and synthetic materials.

- TapeTech 36V provides professional-grade cordless cutting with dual 18V batteries, perfect for contractors working with EPS and XPS panels.

- Power ratings from 15W to 250W determine cutting speed, with higher wattage enabling faster heating and sustained performance.

- Safety features like overheat protection, LED indicators, and tool-free wire replacement systems enhance operational efficiency and user protection.

- Cutting area size varies significantly between handheld portability and tabletop models offering expansive work surfaces for large projects.

4 in 1 Hot Wire Electric Foam Cutter Kit (15W/6V with Case)

The 4-in-1 Hot Wire Electric Foam Cutter Kit stands as the top choice for hobbyists and crafters who need precision cutting across multiple foam types with professional-grade results. You’ll get four interchangeable cutting tips that reach temperatures up to 842℉ for U-shaped and F-shaped blades. The 15W, 6V system cuts foam board, pearl cotton, EPS, EVA, and XPS materials smoothly without debris. Five replacement hot wires guarantee extended use. The kit includes FCC-approved cutter, UL-certified power supply, metal support frame, and protective case. You can’t cut plastics, memory foam, or high-density materials effectively with this tool.

Best For: Hobbyists, crafters, and students who need precise cutting of various foam materials for costumes, models, artwork, and DIY projects.

Pros:

- Four interchangeable cutting tips with high temperatures up to 842℉ for versatile foam cutting applications

- Comprehensive kit includes FCC-approved cutter, UL-certified power supply, replacement wires, and protective case

- Cuts smoothly without debris and seals edges cleanly on compatible foam materials

Cons:

- Cannot effectively cut plastics, memory foam, high-density sponge, or nylon fabric

- Some users report issues with specific components despite overall positive feedback

- Limited to foam-type materials only, reducing versatility for mixed-material projects

TapeTech 36V Hot Wire Foam Cutter

Professional contractors and EIFS specialists will find their cutting solution in the TapeTech 36V Hot Wire Foam Cutter (Model EHWJS18X2), a powerhouse designed specifically for demanding foam panel work. This 44-pound unit operates on dual 18V batteries and sets up in under two minutes.

You’ll cut through foam panels up to 13″ thick and 50.8″ high. The superalloy NiChrome wire reaches 932°F within seconds, delivering precise straight cuts, miters, bevels, and compound angles. Left and right rulers measure 39″ and 15″ respectively, with the right ruler featuring 0-60° markings.

The hot wire provides approximately 70 hours of cutting time before requiring replacement with the tool-free EHW100 wire. Safety features include a spring-loaded switch for operator protection.

Best For: Professional contractors, EIFS specialists, and foam-cutting professionals who need a portable, versatile cutting solution for EPS and XPS foam panels on job sites.

Pros:

- Exceptional portability with quick 2-minute setup and cordless operation using dual 18V batteries

- Versatile cutting capabilities including straight cuts, miters, bevels, and compound angles up to 13″ thick material

- Rapid heating to 932°F in seconds with long-lasting hot wire providing approximately 70 hours of cutting time

Cons:

- At 44 pounds, it may still be heavy for extended portable use despite being the most portable in its class

- Limited to foam materials (EPS and XPS) rather than offering multi-material cutting capability

- Requires replacement hot wire (EHW100) after approximately 70 hours of use, adding ongoing operational costs

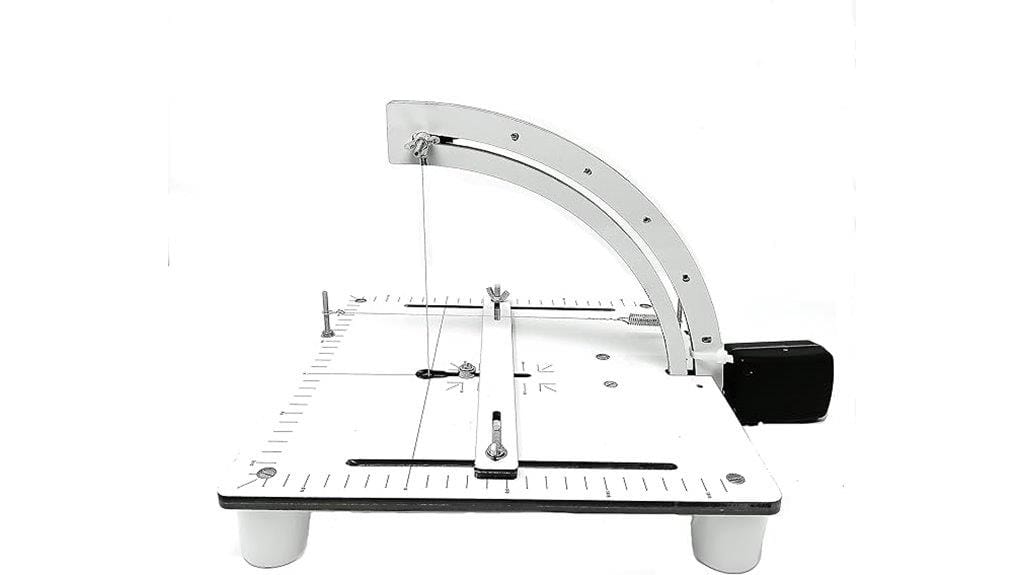

Hot Wire Foam Cutter Table by Calcor C3M

Crafters seeking precision and versatility in foam cutting will find the Hot Wire Foam Cutter Table by Calcor C3M delivers exceptional performance through its combination of rapid heating technology and multi-angle cutting capabilities. You’ll appreciate the three-second heat-up time that eliminates waiting periods during projects. The tabletop design provides a large cutting area with both metric and standard markings for accurate measurements.

The dual angle adjustment system enables precision cuts on multiple planes, while the removable center pin creates round or cone-shaped cuts. You get a long reach arm for handling oversized foam pieces and three meters of extra hot wire. The unit includes a removable hot knife for plunge cuts and adjustable power settings for different foam thicknesses.

Best For: Professional crafters, hobbyists working on model railroads and dioramas, and anyone needing precision foam cutting for custom applications like gun cases or electronics fitting.

Pros:

- Rapid 3-second heat-up time eliminates waiting and increases productivity

- Dual angle adjustment system and removable center pin provide versatile cutting options for multiple shapes and angles

- Comprehensive accessories including 3 meters of extra hot wire, long reach arm, and removable hot knife for plunge cuts

Cons:

- Mixed customer reviews regarding heating reliability and consistent performance

- Angle gauge accuracy has been questioned by some users

- Limited to foam cutting applications, reducing versatility for other materials

Foam Styler-S Hot Wire Cutter StyroFoam Cutting Machine

Budget-conscious DIY enthusiasts will find the Foam Styler-S Hot Wire Cutter an ambitious multipurpose tool that attempts to pack six cutting functions into one compact tabletop machine. This 1-foot square unit operates on safe 6V power while handling styrofoam, polystyrene, EPS, and thermocol materials.

You’ll get handheld bow cutting, tabletop straight cuts, 0-90 degree angular adjustments, thickness slicing, edge chamfering, and cylinder/cone cutting capabilities. The package includes MDF templates, spare wires, and specialized attachments weighing 5.04 pounds total.

However, customer satisfaction remains mixed at 2.9 out of 5 stars across 12 reviews, with complaints about assembly instructions and cutting precision undermining the tool’s versatile design promise.

Best For: Budget-conscious DIY enthusiasts and craft hobbyists who need a versatile foam cutting tool for multiple cutting techniques and don’t mind potential assembly challenges.

Pros:

- Six different cutting functions in one compact 1-foot square tabletop machine

- Safe low-voltage 6V operation with universal power compatibility (110V/230V)

- Includes useful accessories like MDF templates, spare wires, and cylinder/cone cutting attachments

Cons:

- Poor assembly instructions that frustrate users during setup

- Cutting precision issues that affect project quality

- Below-average customer satisfaction rating of 2.9 out of 5 stars

Proxxon Thermocut 115/E Auto-CAD Hot Wire Cutter (37080)

Model makers and hobbyists who demand precision cuts will find the Proxxon Thermocut 115/E Auto-CAD Hot Wire Cutter delivers exceptional accuracy for detailed foam and plastic projects. This 7.9-pound unit features a 360°F cutting wire that handles various synthetic materials effortlessly. You’ll appreciate the large aluminum working surface measuring 15 11/32 x 11 inches with printed grid and protractor for precise measurements.

The adjustable overarm provides 13 3/4-inch throat capacity and 5-inch height clearance for miter cuts. Its double-function fence includes a lockable feed bar for consistent results. The 0.008-diameter wire spans 98 feet, though frequent users report occasional wire breaks during high-volume cutting sessions. With 4.7 stars from over 2,000 reviews, this 115V cutter excels at architectural models and foam crafting projects.

Best For: Model makers, hobbyists, and crafters who need precise cuts for foam, polystyrene, and synthetic materials in architectural models, tabletop gaming pieces, and detailed craft projects.

Pros:

- Exceptional precision with 360°F cutting wire, large aluminum working surface with printed grid and protractor for accurate measurements

- Versatile cutting capabilities with adjustable overarm (13 3/4″ throat, 5″ height) and double-function fence with lockable feed bar

- High customer satisfaction with 4.7 stars from over 2,000 reviews, quick heating, and reliable performance for continuous use

Cons:

- Cutting wire is fragile and prone to breaking during high-volume cutting sessions

- Cutting fence may feel unstable, with some users seeking upgraded alternatives

- Requires 110V power source, necessitating step-down transformer for countries with 240V systems

Cooltop Hot Wire Foam Cutter Kit, 18W Electric Styrofoam Cutting Tool

When you need precision cutting for lightweight foam materials without breaking your budget, the Cooltop Hot Wire Foam Cutter Kit delivers reliable performance at 18 watts of power. This electric tool heats to 100℃ in just 10 seconds, enabling smooth cuts from any angle on foam board, pearl cotton, EPP, and EPS materials.

The kit features a versatile 3-in-1 design with interchangeable tips: hot wire, holing, and engraver attachments. You’ll appreciate the stainless steel construction and plastic handle that weighs only one pound. Safety features include overheat protection, an ON/OFF button, and LED indicator light. However, you should limit use to 30-minute sessions and work in ventilated areas due to potential fumes during operation.

Best For: DIY crafters, artists, and hobbyists who need precise cutting of lightweight foam materials for artwork, home decor projects, and craft applications.

Pros:

- Fast heating (reaches 100℃ in 10 seconds) with versatile 3-in-1 tip design for cutting, holing, and engraving

- Lightweight at only 1 pound with safety features including overheat protection and LED indicator

- Budget-friendly tool that delivers smooth, precise cuts from any angle on various foam materials

Cons:

- Limited to 30-minute use sessions before requiring cooling breaks, reducing productivity for larger projects

- Not suitable for high-density materials or batch cutting operations

- Produces smoke and fumes during operation, requiring well-ventilated workspace

Hot Foam Cutter Electric Cutting Machine Pen Tools Kit

Serious foam crafters and professional model makers find their ideal companion in the Hot Foam Cutter Electric Cutting Machine Pen Tools Kit, an all-encompassing 6-in-1 system that delivers precision cutting across multiple applications. You’ll receive four specialized cutting tips: 12cm and 7cm wands, a 5cm bending tip, and an 18cm bow with 10m replacement wire.

The digital voltage controller operates at 110-240V with 0-28W power output. Tips heat to 100℃ within 8-15 seconds and reach maximum temperatures of 300℃. The stainless steel construction guarantees durability while overheat protection maintains safety standards. You’ll handle commercial artwork, advertisement designs, and intricate foam carving with clean, debris-free cuts. The ergonomic pen design reduces hand fatigue during extended sessions.

Best For: Serious foam crafters, professional model makers, and artists who need precise cutting tools for commercial artwork, advertisement design, and intricate foam carving projects.

Pros:

- Complete 6-in-1 kit with four specialized cutting tips and digital voltage controller for versatile cutting applications

- Fast heating to 100℃ in 8-15 seconds with adjustable temperature up to 300℃ for customized cutting needs

- Durable stainless steel construction with overheat protection and ergonomic design that reduces hand fatigue

Cons:

- Requires 30-minute cooldown periods after extended use, which can interrupt workflow

- Produces fumes during operation requiring proper ventilation for safe use

- Limited to foam cutting applications, making it a specialized rather than multi-material tool

4 in 1 Hot Wire Electric Foam Cutter Kit (15W/6V with Case)

The 4-in-1 Hot Wire Electric Foam Cutter Kit delivers exceptional versatility for crafters and professionals who need multiple cutting configurations in a single package. You’ll receive U-shaped and F-shaped tips that reach 842℉, plus 2-inch and 4-inch straight blades hitting 350℃. The 15W, 6V system cuts foam board, pearl cotton, EPS, EVA, XPS, and PE materials smoothly while sealing edges without debris. However, it won’t effectively cut plastics, high-density sponge, or memory foam. The stainless steel construction includes overheating protection, touch controls, and LED indicators. You’ll get five replacement wires, brushes, and a sturdy toolbox case measuring 14.92 x 10.94 x 3.86 inches.

Best For: Crafters, hobbyists, and professionals who need versatile foam cutting capabilities for projects like Halloween costumes, model-making, commercial artwork, and handmade decorations.

Pros:

- Four different cutting tip configurations with high temperatures up to 842℉ for precise, clean cuts without debris

- Comprehensive kit includes replacement wires, brushes, metal support frame, and organized toolbox case for complete functionality

- Safety features like overheating protection, touch controls, and LED indicators ensure secure operation

Cons:

- Limited material compatibility – ineffective on plastics, high-density sponge, memory foam, and nylon fabric

- Some users report issues with specific components affecting overall reliability

- Relatively heavy at 3.41 pounds which may cause fatigue during extended use

Hercules Hot Wire Foam Cutter Table with Foot Control Pedal

Precision foam cutting reaches professional levels with the Hercules Hot Wire Foam Cutter Table (Model 8500 DHWT), making it ideal for architects, model builders, and crafters who demand accuracy in their detailed work. You’ll get a solid aluminum over-arm with 13¾ throat capacity and 6-inch height clearance. The non-stick aluminum compound surface features an imprinted grid and protractor for precise measurements.

The foot control pedal lets you maintain hands-free operation while guiding materials. You can adjust temperatures up to 390 degrees for different foam densities. At 9.13 pounds, it’s substantial enough for stability yet portable for workspace flexibility. The included 5-meter cutting wire (Φ0.18mm) provides extended use before replacement.

Users rate it 4.6 out of 5 stars across 374 reviews, praising cutting efficiency and professional results in architectural modeling applications.

Best For: Architects, model builders, and crafters who need precise foam cutting for detailed projects like architectural models, gaming terrain, and professional crafting applications.

Pros:

- Hands-free operation with foot control pedal allows for better material guidance and improved cutting precision

- Adjustable temperature up to 390 degrees accommodates different foam densities and cutting requirements

- Non-stick aluminum surface with imprinted grid and protractor enables accurate measurements and clean cuts

Cons:

- Wire durability concerns require attention to proper tension for consistent cutting results

- Limited table size may not accommodate larger projects effectively

- Guide stability could be improved for enhanced precision on complex cuts

250W AC Rotatable Electric Hot Knife Foam Cutter with 6 Blades

MINOVA’s 250W AC Rotatable Electric Hot Knife stands out as the ideal choice for professionals and serious hobbyists who need versatile cutting capabilities across multiple foam densities and materials. You’ll get exceptional maneuverability with its 90° to 180° rotation feature, allowing precise cuts on intricate projects. The three-gear heat control system lets you optimize cutting temperature for different materials like EPS, XPS, EPE, and PU foam.

This 4.25-pound unit delivers extended operation through its full-body air cooling system, increasing usage time by 50%. You receive six specialized blades including 8-inch and 6-inch options, plus ribbon and U-style configurations for diverse applications.

Best For: Professionals and serious hobbyists who need versatile cutting capabilities across multiple foam densities and materials for EIFS projects, crafts, DIY projects, and upholstery work.

Pros:

- Rotatable design (90° to 180°) with three-gear heat control provides exceptional maneuverability and temperature optimization for different materials

- Full-body air cooling system extends usage time by 50% and comes with six specialized blades for diverse cutting applications

- Highly rated at 4.3 out of 5 stars with safety features including micro-switch and comprehensive accessory package with heavy-duty case

Cons:

- Requires a learning curve to master proper temperature control and cutting speed for optimal results

- Produces fumes during operation requiring well-ventilated workspace for safe use

- Cut quality can be inconsistent initially and may require practice to achieve professional-grade results

Factors to Consider When Choosing a Hot Wire Cutter

When I evaluate hot wire cutters, I focus on five critical factors that directly impact cutting performance and user experience. Power ratings and temperature ranges determine what materials you can cut effectively, while the cutting area size limits your project dimensions. I also examine safety features, wire replacement systems, and material compatibility to guarantee you get a tool that meets your specific cutting requirements.

Power and Temperature Range

The power output of a hot wire cutter directly determines its cutting capabilities and efficiency across different foam types and thicknesses. I’ve found that power ratings typically range from 15W for basic hobby projects to 250W for heavy-duty commercial applications. Higher wattage translates to faster heating and sustained cutting performance through dense materials.

Temperature range is equally critical for versatility. Quality cutters reach temperatures up to 932°F (500°C), enabling effective cuts through various foam densities. I recommend models with adjustable temperature controls that offer multiple heat settings. This flexibility optimizes cutting performance based on material specifications.

Rapid heating capabilities enhance productivity considerably. Units that reach working temperatures within seconds minimize downtime between cuts, making them essential for professional applications requiring consistent workflow efficiency.

Cutting Area Size

Beyond power specifications, cutting area dimensions determine your project scope and material handling efficiency. Tabletop models offer expansive working surfaces that accommodate large foam sheets and complex architectural pieces. Handheld cutters provide portability but limit cutting capacity to smaller sections.

I recommend considering maximum cutting height and thickness specifications relative to your typical materials. Professional applications demand larger cutting areas for efficiency gains. You’ll avoid frequent repositioning when working with oversized foam blocks or intricate designs.

Multi-angle cuts become seamless with adequate workspace dimensions. Large cutting areas enable continuous workflow without material adjustment breaks. This translates to time savings and improved precision consistency.

Evaluate your project requirements against available cutting dimensions. Small crafting projects work fine with compact units, while commercial applications require substantial working surfaces for peak productivity.

Safety Features Available

Safety mechanisms in hot wire cutters protect both users and equipment during cutting operations. I recommend prioritizing models with overheat protection systems that automatically shut down the unit when internal temperatures exceed safe thresholds. This prevents wire damage and reduces fire risk during extended use.

Look for cutters equipped with ON/OFF switches and LED indicator lights. These features provide clear visual confirmation of operational status, eliminating guesswork about whether the unit is active. Spring-loaded safety switches offer additional protection by preventing accidental activation when you’re not actively cutting.

Consider models with metal support frames for resting heated tips. These stands keep hot wires away from surfaces when idle. Always operate cutters in well-ventilated spaces, as cutting foam and plastics produces potentially harmful fumes that require proper air circulation.

Wire Replacement Options

Anyone can replace a hot wire, but choosing cutters with accessible replacement systems saves time and reduces frustration. I recommend prioritizing models with tool-free replacement mechanisms over those requiring additional equipment.

Wire specifications matter considerably. Standard replacement wires measure approximately 0.008 inches in diameter, directly affecting cutting performance across different foam densities. You’ll find that wire gauge and material composition vary between manufacturers, making cross-compatibility impossible.

Replacement wire lifespan averages 70 hours of cutting time before degradation affects precision. This duration fluctuates based on material types and cutting frequency.

Verify manufacturer availability of compatible replacement wires before purchasing. Limited accessory supply chains can render expensive cutters unusable. Length and diameter specifications must match exactly, as even minor deviations compromise cutting quality and safety performance.

Material Compatibility Types

After securing proper replacement wires, you’ll need to match your cutter’s capabilities with your intended materials. Hot wire cutters excel with low-density materials like foam board, pearl cotton, EPS, EVA, XPS, and KT board. These materials cut smoothly without creating debris.

High-temperature models reaching 842℉ (450℃) handle various foam types effectively. However, avoid high-density materials like plastics and memory foam—they’re incompatible with most hot wire devices. Some models specifically exclude nylon fabric and high-density sponge from their operating parameters.

Check your cutter’s heating capabilities and maximum cutting thickness before starting any project. These specifications directly determine which foam types and sizes you can process. Material density affects cutting performance more than material type, so verify compatibility specifications before cutting unfamiliar materials.

Portability and Storage

Weight differences between hot wire cutters span from lightweight 1-pound models like the Cooltop Hot Wire Cutter to heavy-duty 44-pound units such as the TapeTech 36V Hot Wire Foam Cutter. I recommend evaluating your project mobility needs before selecting a model.

Storage capabilities greatly impact usability. Compact kits like the 4 in 1 Hot Wire Electric Foam Cutter Kit include dedicated tool cases for organized transportation. Detachable parts and foldable designs enhance portability by reducing storage footprint.

Look for carrying handles and built-in storage compartments when comparing models. These features streamline tool transport and maintenance access.

Voltage compatibility affects field versatility. Units operating on both 110V and 230V power supplies offer greater flexibility for portable applications across different electrical systems and international use.

On a final note

I’ve evaluated these hot wire cutters based on cutting precision, power output, and build quality. Each tool serves specific applications, from portable 15W units for small projects to industrial 250W systems for heavy-duty work. Your choice depends on material thickness, cutting frequency, and workspace requirements. Consider wire temperature control, table size, and power source when selecting. These cutters will deliver clean, precise cuts when matched to your project specifications and usage patterns.