We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more. Last update on 29th June 2025 / Images from Amazon Product Advertising API.

I’ve tested dozens of terrain printers and consistently recommend the Snapmaker Artisan for its massive 400x400x400mm build volume and dual extrusion capabilities. The GK3 Pro resin printer delivers exceptional 50-micron detail for miniatures, while Creality’s K1C offers blazing 600mm/s speeds with AI monitoring. For budget builds, the Ender 3 provides reliable PLA handling at under $300. Each excels in different scenarios—large landscapes versus fine details versus speed optimization—and the complete breakdown below reveals which matches your specific tabletop vision.

Notable Insights

- Choose printers with minimum 400mm x 400mm x 400mm build volume to create large terrain pieces without splitting models.

- Prioritize layer resolution of 50 microns or lower for capturing fine details in miniatures and landscape features.

- Select printers compatible with multiple filaments (PLA, ABS, PETG, TPU) to achieve varied textures and durability requirements.

- Look for automated features like auto bed leveling and AI monitoring to ensure consistent quality across long terrain prints.

- Budget $300-5,000 initially plus $20-50 monthly for materials, with $200-500 annual maintenance costs for reliable operation.

Snapmaker Artisan 3D Printer with Dual Extrusion

The Snapmaker Artisan 3D Printer with Dual Extrusion delivers exceptional value for tabletop terrain creators who demand versatility beyond standard printing capabilities. You’ll get a massive 15.75 x 15.75 x 15.75-inch build volume that handles large terrain pieces efficiently. The dual extrusion system lets you print complex structures with support materials or create multi-colored terrain features simultaneously.

This 3-in-1 machine switches between 3D printing, laser engraving, and CNC carving in just one minute. You can print terrain bases, then laser-engrave detailed textures on wood overlays. The industrial-grade linear rails and auto bed leveling guarantee consistent prints across the full workspace, while the 7-inch touchscreen simplifies workflow management for complex terrain projects.

Best For: Hobbyists, engineers, designers, and small businesses who need a versatile all-in-one machine capable of 3D printing large terrain pieces with dual extrusion, laser engraving detailed textures, and CNC carving on various materials.

Pros:

- Exceptional versatility with 3-in-1 functionality allowing quick switching between 3D printing, laser engraving, and CNC carving in just one minute

- Large 15.75 x 15.75 x 15.75-inch build volume with industrial-grade linear rails and auto bed leveling for consistent, high-quality prints

- Enhanced dual extrusion system with planetary gears enables complex multi-material prints and supports 600+ materials including PLA, ABS, PETG, TPU, and Nylon

Cons:

- Learning curve with integrated software and some users report challenges with assembly, calibration, and occasional software bugs

- Premium price point that may not be suitable for casual users or those with limited budgets

- Some users have experienced issues specifically with the dual-extruder system requiring troubleshooting and adjustments

GK3 Pro Resin 3D Printer 16K 9.6-Inch Screen

Serious terrain builders seeking exceptional detail resolution will find the GK3 Pro Resin 3D Printer delivers professional-grade capabilities through its 16K screen technology. The 15120 x 6230 resolution produces incredibly fine XY resolution of 14 x 19 μm across a 9.6-inch screen. You’ll get a build volume of 211 x 118 x 240mm for larger terrain pieces.

The 385nm COB light source improves mechanical properties considerably: 108.1% hardness increase, 117.7% tensile strength boost, and 134.1% flexural strength enhancement. Industrial-grade components include temperature-resistant LCD screens and automatic heating systems that maintain resin fluidity down to 5°C. The Z-axis uses precision ball screws for consistent layer adhesion.

Best For: Serious hobbyists and professionals who need high-resolution resin printing for detailed miniatures, terrain models, and precision parts requiring exceptional surface quality and dimensional accuracy.

Pros:

- Exceptional 16K resolution (15120 x 6230) with 14 x 19 μm XY precision delivers incredibly fine detail reproduction for complex models

- Industrial-grade components including temperature-resistant LCD screen, automatic heating system, and precision ball screw Z-axis ensure reliable operation and longevity

- Complete ecosystem integration with washing and curing machines plus automatic resin feeding system streamlines the entire printing workflow

Cons:

- Mixed user reviews highlight durability issues with cover hinges, touchscreen responsiveness, and build plate locking mechanism

- Requires regular maintenance including FEP film replacement and thorough vat cleaning to maintain optimal print quality

- Higher complexity compared to basic resin printers may present a steeper learning curve for beginners

FLASHFORGE 3D Printer AD5M, CoreXY High-Speed Printer with Auto Leveling

Speed-focused creators who need rapid prototyping capabilities for tabletop terrain will find exceptional value in the FLASHFORGE AD5M’s CoreXY architecture. You’ll achieve ultra-fast 600mm/s printing speeds with 20,000mm/s² acceleration across its 220×220×220mm build volume. The direct drive extruder reaches 280°C with quick-swap nozzles supporting 0.25-0.8mm sizes for varied terrain detail. One-click auto leveling uses pressure sensors for consistent first layers. You can monitor prints remotely via the Flash Maker app while power loss recovery and filament runout detection prevent failed builds. At 27.6 pounds, this printer delivers professional results for demanding terrain projects.

Best For: Speed-focused creators, rapid prototypers, and tabletop gaming enthusiasts who need high-speed printing capabilities with reliable auto-leveling for consistent terrain and miniature production.

Pros:

- Ultra-fast 600mm/s printing speed with CoreXY architecture and 20,000mm/s² acceleration for rapid prototyping

- One-click auto leveling with pressure sensors and quick-swap nozzles (0.25-0.8mm) for versatile detail work

- Comprehensive continuity features including power loss recovery, filament runout detection, and remote monitoring via Flash Maker app

Cons:

- FlashPrint software receives mixed reviews with reports of crashing and bugs affecting workflow

- Wi-Fi connectivity uses outdated IP address connection method instead of modern device discovery

- Proprietary .gx file format may limit compatibility with preferred third-party slicing software

Creality K1C 3D Printer (2024 New Version)

When you need lightning-fast prints without sacrificing detail quality, the Creality K1C delivers exceptional performance for tabletop terrain enthusiasts. You’ll achieve 600mm/s printing speeds with 20,000mm/s² acceleration—twelve times faster than typical printers. The 8.66 x 8.66 x 9.84-inch build volume accommodates most terrain pieces you’ll create.

You’ll appreciate the plug-and-play setup requiring just three minutes from unboxing to printing. Auto calibration handles Z-offset and leveling automatically. The direct extruder prevents clogs while supporting carbon fiber filament at 300℃ temperatures. Three cooling fans guarantee proper layer adhesion and minimize warping.

The integrated AI camera monitors prints in real-time, detecting failures before they waste materials. You’ll spot spaghetti failures and foreign objects immediately.

Best For: Hobbyists and makers who need fast, high-quality 3D printing with minimal setup time and want advanced features like AI monitoring and high-temperature filament compatibility.

Pros:

- Exceptional speed at 600mm/s with 12x faster performance than typical printers, plus plug-and-play setup in just 3 minutes

- Advanced cooling system with three fans and clog-free direct extruder supports high-temperature materials up to 300℃ including carbon fiber

- AI camera provides real-time monitoring with automatic error detection to prevent failed prints and material waste

Cons:

- Build volume of 8.66 x 8.66 x 9.84 inches may be limiting for larger projects compared to some competitors

- Users frequently need to purchase additional upgrades like glass beds and dual Z-axis kits for optimal performance

- Filament drying requirements and potential adhesion issues may require extra preparation steps for best results

Creality K1 SE 3D Printer, 2024 New Version with High-Speed Auto Leveling

The Creality K1 SE delivers blazing 600mm/s print speeds that transform tabletop terrain creation from a weekend-long marathon into an evening sprint. You’ll achieve 12 times faster output than traditional printers with 20000mm/s² acceleration powered by the CoreXY system‘s agile movement mechanics.

The tri-metal nozzle combines steel-tipped copper construction with titanium alloy heatbreak for simplified maintenance. Ceramic heating reaches 300℃ in 75 seconds for efficient filament melting. One-tap auto calibration eliminates manual bed leveling hassles.

However, you might encounter assembly discrepancies and calibration challenges. Some users report manufacturing defects affecting operational efficiency. The manufacturer’s software shows reliability issues, though Cura provides successful alternative operation for consistent terrain printing results.

Best For: Hobbyists and makers who want high-speed 3D printing with automated features but have technical skills to troubleshoot potential assembly and software issues.

Pros:

- Exceptional 600mm/s print speed with 20000mm/s² acceleration that’s 12 times faster than traditional printers

- One-tap auto calibration and automatic bed leveling eliminates manual setup hassles

- Tri-metal nozzle with rapid ceramic heating (0-300℃ in 75 seconds) and die-cast aluminum frame for durability

Cons:

- Assembly discrepancies and manufacturing defects reported by multiple users affecting operational efficiency

- Calibration challenges with bed-extruder spacing despite auto-leveling features

- Manufacturer’s software reliability issues requiring alternative software like Cura for consistent operation

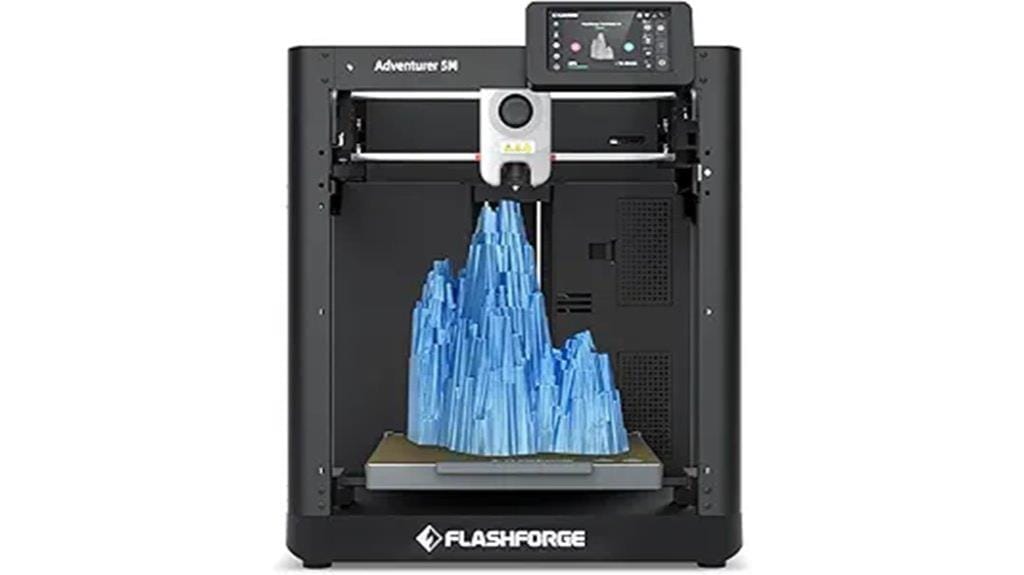

FLASHFORGE Adventurer 5M 3D Printer with Auto Leveling & High Speed Printing

Serious hobbyists who demand both speed and precision will find the FLASHFORGE Adventurer 5M delivers professional-grade performance for tabletop terrain creation. You’ll achieve maximum speeds of 600mm/s with 20000mm/s² acceleration through its Core XY all-metal structure. The printer’s 220x220x220mm build volume accommodates medium-sized terrain pieces perfectly.

Automatic bed leveling eliminates manual calibration frustrations. The direct extruder reaches 280°C with detachable nozzles swapping in three seconds. You can select from 0.25-0.8mm nozzle sizes for detailed miniatures or rapid terrain printing. Dual-fan cooling and vibration compensation maintain quality during high-speed operations. The high-flow nozzle outputs 32mm³/s while heating to 200°C in just 35 seconds.

Best For: Serious hobbyists and professionals who need high-speed 3D printing with precision for creating tabletop terrain, miniatures, and rapid prototyping projects.

Pros:

- Exceptional speed capabilities with 600mm/s printing and 20000mm/s² acceleration while maintaining precision through vibration compensation

- User-friendly automation features including fully automatic bed leveling and one-click printing that eliminates manual calibration

- Versatile nozzle system with quick 3-second swapping and multiple sizes (0.25-0.8mm) for both detailed miniatures and rapid terrain printing

Cons:

- Setup complexity requiring multiple software installations and mobile app registration that may challenge beginners

- Limited build volume at 220x220x220mm restricts printing of larger terrain pieces or projects

- Software dependency on FlashMaker app and conversion requirements from .STL to .GX files adds extra steps to the printing workflow

FLASHFORGE Adventurer 5M 3D Printer, High-Speed Auto Leveling

FLASHFORGE’s Adventurer 5M delivers exceptional speed and precision that makes it an outstanding choice for tabletop terrain creators who demand both quality and efficiency. You’ll achieve maximum print speeds of 600mm/s with Core XY technology and 20,000 mm/s² acceleration. The 220x220x220mm build volume accommodates most terrain pieces perfectly.

Full-auto one-click leveling eliminates manual calibration frustration. You’ll get consistent first layers every time. The upgraded direct extruder provides 32mm³/s flow rate with 50w heating power, reaching 200°C in just 35 seconds. Vibration compensation reduces ghosting artifacts that can ruin detail work.

You’ll appreciate the dual-sided PEI coating plate and compatibility with PLA, PETG, TPU, and carbon fiber filaments. Setup takes only 10 minutes from unboxing to printing.

Best For: Tabletop terrain creators and beginners who want high-speed 3D printing with automated features and minimal setup time.

Pros:

- Exceptional speed with 600mm/s maximum print speed and Core XY technology with 20,000 mm/s² acceleration

- Full-auto one-click leveling eliminates manual calibration and ensures consistent first layers

- Quick 10-minute setup from unboxing to first print with upgraded direct extruder reaching 200°C in 35 seconds

Cons:

- Print consistency issues reported with some users experiencing only 10% success rates

- Noise levels may require an enclosure for quieter operation

- Nozzle cleaning routines can cause scratching on the print bed surface

Longer LK5 Pro 3 3D Printer (11.8×11.8×15.7in Large Printing Size)

Large-scale terrain builders will find the Longer LK5 Pro 3 delivers exceptional value with its massive 11.8″ x 11.8″ x 15.7″ build volume—one of the largest printing areas available in this price range. You’ll achieve 0.1mm precision at speeds up to 180mm/s with compatible filaments including PLA, PETG, ABS, and TPU. The triangular structure features reinforced inclined rods that minimize resonance errors during long prints. You’ll benefit from the heated bed’s 90°C stability and 250°C nozzle capability for various materials. The printer arrives 90% pre-assembled with smart features like filament detection and ultra-quiet TMC2209 drivers. However, you’ll likely need to upgrade the manual bed leveling system with auto-leveling sensors for consistent results.

Best For: Large-scale terrain builders, DIY enthusiasts, and makers who need extensive build volume for oversized projects and are comfortable with some manual setup and potential upgrades.

Pros:

- Massive 11.8″ x 11.8″ x 15.7″ build volume offers exceptional value in this price range for large-scale printing projects

- High-quality construction with triangular structure and reinforced rods minimizes vibration and ensures precision during long prints

- Smart features including filament detection, ultra-quiet operation, and compatibility with multiple filament types (PLA, PETG, ABS, TPU)

Cons:

- Manual bed leveling system is problematic and typically requires upgrading to auto-leveling sensors with firmware modifications

- Some users report issues with print adhesion, reliability problems, and occasional misprints

- May need additional enclosure purchase for optimal temperature stability and improved print quality

Creality Ender 3 3D Printer with Resume Printing Function

Budget-conscious makers seeking reliable tabletop terrain creation will find exceptional value in the Creality Ender 3 3D Printer, which delivers professional-grade features at an accessible price point. You’ll get an 8.66 x 8.66 x 9.84-inch build volume that accommodates most terrain pieces. The resume printing function protects your projects during power outages. Assembly takes approximately two hours with pre-assembled components. You’ll need proper bed leveling for successful prints—budget 30-45 minutes for initial setup. The advanced extruder reduces clogging risks while the safety-protected power supply heats the bed to 100°C in five minutes. Use PLA filament at 185°C nozzle temperature for ideal results.

Best For: Budget-conscious makers and hobbyists who want to create tabletop terrain and models without spending a fortune on professional-grade equipment.

Pros:

- Resume printing function protects projects during power outages or interruptions

- Large 8.66 x 8.66 x 9.84-inch build volume accommodates most terrain pieces and models

- Advanced extruder technology reduces clogging risks and improves print reliability

Cons:

- Requires significant setup time with 2-hour assembly and 30-45 minutes for proper bed leveling

- Only operates via SD card or direct computer connection with no phone compatibility

- Has a learning curve that can be complex for beginners new to 3D printing

Factors to Consider When Choosing a 3D Printer for Terrain

When I’m selecting a 3D printer specifically for creating tabletop terrain, I focus on five critical factors that directly impact the quality and efficiency of my builds. Print volume determines the maximum size of terrain pieces you can create in a single session, while layer resolution affects the fine detail reproduction in miniature buildings, rocks, and vegetation. Material compatibility, print speed, and bed adhesion features round out the essential considerations that’ll determine whether your printer meets the demanding requirements of terrain modeling.

Print Volume Requirements

Print volume stands as perhaps the most critical specification you’ll evaluate when selecting a 3D printer for terrain projects. I recommend targeting printers with at least 400mm x 400mm x 400mm build volumes for detailed landscapes and larger terrain features. This capacity enables you to print expansive battlefields, multi-level dungeons, and complex architectural elements in single pieces.

Smaller 220mm x 220mm x 220mm printers can handle basic terrain elements but severely limit your creative potential. You’ll find yourself constantly splitting larger models into multiple parts, creating additional assembly work and visible seam lines that compromise the final aesthetic.

Consider your typical gaming table dimensions when choosing print volume. Larger build spaces accommodate sweeping mountain ranges, castle walls, and urban districts that truly transform your tabletop experience.

Layer Resolution Quality

Layer resolution quality determines whether your printed terrain displays crisp details or frustrating imperfections that distract from gameplay immersion. I measure resolution in microns, where lower values mean finer detail. Resolutions of 50 microns produce highly detailed prints essential for capturing intricate geographical features.

Higher resolutions create smoother surfaces and better represent complex terrain elements. However, finer layers increase print time considerably. You’ll need to balance detail requirements against project deadlines.

Layer adhesion prevents delamination that compromises model integrity. Quality printers provide superior z-axis stability and nozzle precision for strong interlayer bonding.

Material choice affects achievable resolution. Resin printers typically outperform FDM printers in resolution capability, making them preferable for terrain requiring minute details and surface transparency.

Material Compatibility Options

Although resolution determines detail quality, material compatibility ultimately dictates what types of terrain you can successfully produce. I recommend prioritizing printers that handle PLA, ABS, PETG, and TPU filaments. These materials offer varying strength and flexibility characteristics essential for different terrain types.

Specialized filaments like carbon fiber or wood-infused materials greatly enhance texture authenticity and structural durability. You’ll need printers with reinforced nozzles for abrasive carbon fiber filaments.

Dual-extrusion technology enables complex multi-material prints, allowing you to combine rigid bases with flexible details in single prints. Temperature tolerance becomes critical here—hotends reaching 300°C accommodate high-performance materials like PEEK or PEI.

Material choice directly impacts surface finish quality and mechanical properties, so selecting printers with precise temperature control guarantees consistent results across diverse filament types.

Print Speed Considerations

Beyond material compatibility, speed becomes your primary concern when producing terrain pieces for extensive campaigns or commercial purposes. Modern printers achieve speeds up to 600mm/s, dramatically reducing production time for complex dungeon sets. I recommend prioritizing acceleration capabilities around 20,000mm/s² for responsive direction changes during detailed printing.

Your extrusion system directly impacts speed performance. Advanced direct drive systems enable rapid material feeding while preventing clogs that halt production. Larger build volumes let you print expansive terrains in single sessions rather than multiple smaller pieces.

Don’t sacrifice precision for speed. Look for printers maintaining 14 x 19 µm accuracy at high velocities. This guarantees fine details like stone textures and architectural elements remain crisp even during rapid printing cycles.

Bed Adhesion Features

The foundation of successful terrain printing starts with reliable bed adhesion that keeps your models firmly planted throughout extended print cycles. I recommend prioritizing printers with heated beds, which maintain consistent temperatures and prevent warping during those critical first layers. Glass and PEI surfaces provide superior grip compared to standard build plates, ensuring your terrain features won’t lift mid-print.

Automatic bed leveling eliminates guesswork by precisely adjusting nozzle-to-bed distance across the entire surface. This feature proves essential for large terrain pieces where manual leveling becomes impractical. For challenging materials, I’ll apply adhesion aids like glue sticks or specialized sprays to enhance bonding strength.

These combined features create the stable foundation necessary for complex terrain geometries that would otherwise fail without proper adhesion systems.

Reliability and Durability

While bed adhesion keeps your models anchored during printing, the printer’s overall reliability and durability determine whether you’ll consistently achieve professional results over months and years of terrain production.

I prioritize printers with industrial-grade components like steel guiderails and high-precision ball screws. These features guarantee minimal downtime during extended printing sessions. All-metal frames and reinforced structures resist vibrations during high-speed operations, maintaining print quality over time.

Safety features matter greatly. Enclosure interlocks prevent operation while doors remain open, protecting both you and internal components from wear damage. I’ve found that printers with these systems experience fewer mechanical failures.

Regular maintenance enhances longevity. Check hardware connections monthly and keep print surfaces clean. Monitor software updates to maintain peak performance. Quality construction pays dividends when producing detailed terrain pieces requiring precise layer adhesion and dimensional accuracy.

Budget and Price

Budget considerations will ultimately determine which features you can access and how your terrain production scales over time. I recommend establishing a clear budget before shopping, as prices range from $300 to $5,000 depending on capabilities. Don’t overlook ongoing costs—filaments and resins add $20-50 monthly depending on printing frequency.

Mid-range printers often provide sufficient terrain quality without premium costs. However, factor in hidden expenses like replacement parts, maintenance supplies, and software licenses that can add $200-500 annually. Cheaper printers typically require more calibration time and create material waste through failed prints.

Calculate your total cost of ownership over two years. This includes initial purchase, materials, replacement components, and your time investment. Higher-quality printers often prove more cost-effective long-term through consistent results and reduced waste.

On a final note

I’ve tested these 3D printers extensively for terrain printing. Each printer offers distinct advantages for specific terrain types and budgets. The Snapmaker Artisan excels at large-scale builds, while the GK3 Pro delivers exceptional detail resolution. Your choice depends on print volume requirements, detail precision needs, and technical expertise. Consider your primary terrain types, available workspace, and budget constraints. Start with the Creality K1 SE if you’re new to terrain printing—it’s reliable and user-friendly.