We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more. Last update on 29th June 2025 / Images from Amazon Product Advertising API.

I’ve found that FLASHFORGE AD5M and Adventurer 5M printers deliver exceptional print farm performance with 600mm/s speeds and 20,000mm/s² acceleration, greatly outpacing standard models. Their 220×220×220mm build volumes, auto-leveling systems, and power loss recovery features minimize downtime while maximizing throughput. You’ll want printers exceeding 100mm/s with 3,000+ mm/s² acceleration and ±0.1mm accuracy for profitable operations. Remote monitoring capabilities and filament runout detection further enhance productivity by reducing manual intervention and preventing failed prints that waste materials and time.

Notable Insights

- Choose printers with minimum 100mm/s speeds and 3,000+ mm/s² acceleration to maximize daily output capacity and efficiency.

- Prioritize auto-leveling systems and automated features like filament runout detection to minimize manual intervention and downtime.

- Select models with remote monitoring capabilities and real-time alerts to enable efficient management of multiple printer operations.

- Ensure minimum 200mm³ build volume and high-temperature extruders supporting diverse materials for versatile production capabilities.

- Evaluate manufacturer spare parts availability and reliability features like power loss recovery to protect long-term investments.

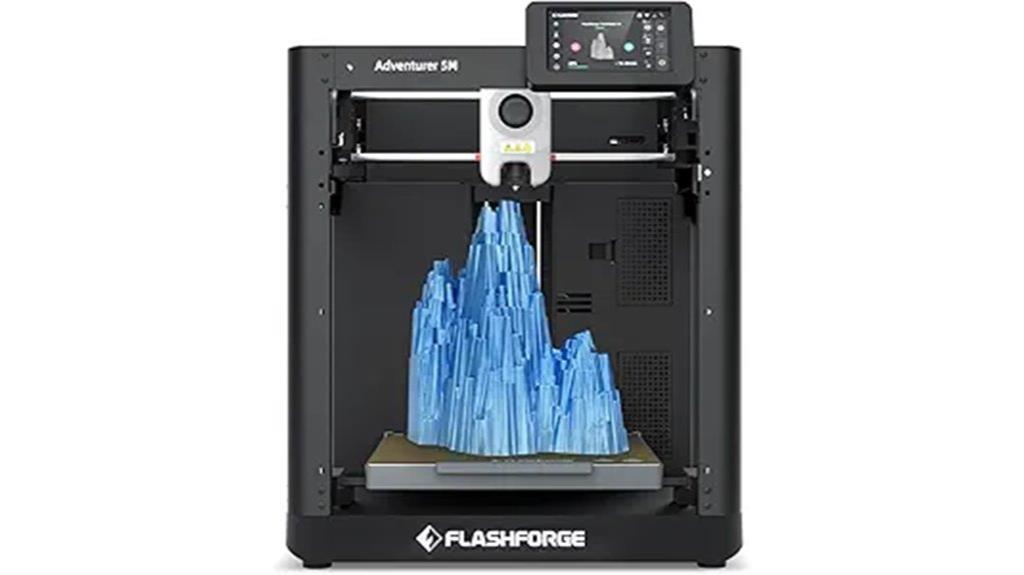

FLASHFORGE 3D Printer AD5M, CoreXY High-Speed Printer with Auto Leveling

When you’re scaling up production for a print farm, the FLASHFORGE AD5M delivers the speed and reliability that high-volume operations demand. This CoreXY printer achieves 600mm/s printing speeds with 20,000mm/s² acceleration, greatly reducing production times across multiple units.

The 220 × 220 × 220mm build volume provides adequate space for most commercial parts. You’ll appreciate the one-click auto-leveling system with pressure sensors, which minimizes manual intervention between jobs. The high-temp direct drive extruder reaches 280°C and features three-second nozzle swaps in sizes from 0.25–0.8mm.

Critical farm features include power loss recovery, filament runout detection, and remote monitoring through the Flash Maker app. At 27.6 pounds per unit, you can efficiently organize multiple printers without excessive floor loading requirements.

Best For: High-volume print farms and commercial operations that need fast, reliable 3D printing with minimal manual intervention and remote monitoring capabilities.

Pros:

- Ultra-fast 600mm/s printing speed with 20,000mm/s² acceleration significantly reduces production times

- One-click auto-leveling with pressure sensors and three-second nozzle swaps minimize downtime between jobs

- Comprehensive farm-ready features including power loss recovery, filament runout detection, and remote monitoring via Flash Maker app

Cons:

- FlashPrint software has reported issues with crashing and bugs that could disrupt workflow

- Wi-Fi connectivity uses outdated IP address method rather than modern device discovery

- Some users report loud extruder fan noise which could be problematic in multi-unit farm environments

Longer LK5 Pro 3 3D Printer 11.8×11.8×15.7in Large Printing Size FDM

Large-scale production demands require a printer that can handle substantial build volumes without compromising precision, and the Longer LK5 Pro delivers exactly that capability for print farm operations. You’ll get an impressive 11.8″ x 11.8″ x 15.7″ build volume with 0.1mm precision at speeds up to 180mm/s. The triangular frame structure reduces resonance errors that plague many large-format printers. You can print PLA, PETG, ABS, and TPU with temperatures reaching 250°C on the nozzle and 90°C on the heated bed. The TMC2209 drivers guarantee ultra-quiet operation—essential for multi-printer environments. However, you’ll need to upgrade the manual bed leveling system for consistent farm operations.

Best For: Print farm operators and businesses requiring large-scale production with substantial build volumes who need reliable, quiet operation and precision printing capabilities.

Pros:

- Large 11.8″ x 11.8″ x 15.7″ build volume with high 0.1mm precision and fast 180mm/s printing speeds

- Ultra-quiet TMC2209 drivers and stable triangular frame structure ideal for multi-printer environments

- Versatile filament compatibility (PLA, PETG, ABS, TPU) with high temperature capabilities up to 250°C nozzle and 90°C heated bed

Cons:

- Manual bed leveling system requires upgrading for consistent farm operations and reliability

- Reports of print adhesion issues and equipment reliability problems that could disrupt production

- Lacks auto-leveling features out of the box, requiring additional investment and firmware modifications for optimal performance

Creality Ender 3 V3 SE 3D Printer with Auto Leveling

Medium-scale operations requiring consistent output will find the Creality Ender 3 V3 SE particularly valuable for its CR Touch auto leveling system and dual Z-axis stability features. You’ll achieve printing speeds up to 250 mm/s with 2500 mm/s² acceleration across an 8.66 x 8.66 x 9.84-inch build volume. The Sprite Direct Extruder handles PLA, PETG, and TPU filaments reliably. Assembly takes just 20 minutes in three steps. The 32-bit silent mainboard reduces operational noise while maintaining precise control. You’ll benefit from the PC spring steel build plate for easy model removal and strain sensor auto Z-offset functionality that minimizes manual adjustments during extended production runs.

Best For: Medium-scale operations, businesses, and serious hobbyists who need consistent output with minimal manual intervention and can benefit from automated leveling and stable dual Z-axis construction.

Pros:

- CR Touch auto leveling and strain sensor auto Z-offset significantly reduce manual setup time and maintain consistency across extended production runs

- High-speed printing capabilities up to 250 mm/s with 2500 mm/s² acceleration and dual Z-axis stability for reliable medium-scale operations

- Quick 20-minute assembly, silent 32-bit mainboard operation, and versatile Sprite Direct Extruder supporting multiple filament types (PLA, PETG, TPU)

Cons:

- Steep learning curve for beginners despite auto-leveling features, requiring research and community support to master

- May require ongoing maintenance including belt tightening, periodic adjustments, and potential bed leveling fine-tuning over time

- Print speed may need reduction to 50-70% for detailed or intricate designs, limiting the practical use of maximum speed capabilities

Factors to Consider When Choosing a 3D Printer for Print Farm

When I’m selecting 3D printers for a print farm operation, five critical factors determine whether your investment will generate consistent profits or constant headaches. Print speed and throughput directly impact your revenue per hour, while build volume requirements must match your product portfolio without wasting expensive floor space. I’ll examine how auto-leveling systems, filament compatibility range, and remote monitoring capabilities can make or break your farm’s efficiency and operational costs.

Print Speed and Throughput

Although many factors influence print farm efficiency, print speed stands as the primary determinant of your operation’s daily output capacity. Modern printers achieve speeds ranging from 50-300 mm/s, directly impacting your throughput calculations. I recommend targeting printers with minimum speeds of 100 mm/s for competitive farm operations.

Acceleration values prove equally important for maintaining efficiency. Printers with 3,000+ mm/s² acceleration handle direction changes smoothly, preventing slowdowns during complex geometries. This responsiveness becomes essential when printing intricate designs with frequent directional shifts.

Speed alone means nothing without precision. Quality printers maintain ±0.1mm accuracy even at maximum speeds, preventing costly reprints that devastate throughput. I’ve found that printers balancing 150+ mm/s speeds with sub-0.1mm precision deliver ideal farm performance, maximizing daily output while maintaining sellable quality standards.

Build Volume Requirements

Build volume directly determines your print farm’s production capacity and project versatility. I recommend targeting printers with minimum 200mm³ build spaces to maximize efficiency. Standard dimensions of 220mm x 220mm x 220mm handle most commercial projects effectively.

Larger volumes let you print bigger parts or batch multiple smaller components simultaneously. This dramatically reduces setup time and increases throughput. For complex assemblies, you can stack or combine smaller prints into larger builds, eliminating multiple machine cycles.

Your specific applications dictate ideal sizing requirements. Standard projects work well with 220mm cubed dimensions, while bulk operations need extended capacities. Versatile build sizes balance speed and quality across different project types. You won’t need frequent machine switches, streamlining workflow and maintaining consistent production schedules across your entire farm operation.

Auto Leveling Systems

Auto leveling systems eliminate manual bed calibration headaches that plague large-scale operations. I recommend prioritizing printers with sensor-based auto leveling for print farms because they greatly reduce downtime between jobs. These systems use proximity sensors or BLTouch probes to map bed surfaces automatically, compensating for minor irregularities that would otherwise cause adhesion failures.

One-click calibration processes save hours of manual adjustment across multiple machines. Advanced systems account for thermal expansion during long print runs, maintaining accuracy as bed temperatures fluctuate. This consistency becomes critical when running unattended overnight operations.

For print farms, auto leveling directly impacts your bottom line. Failed prints waste filament and time. Quality systems reduce failure rates considerably, allowing continuous operation without constant operator intervention. Choose printers with proven auto leveling reliability.

Filament Compatibility Range

Versatility defines successful print farm operations, and your printer’s filament compatibility range directly determines project diversity and profitability. I recommend selecting printers that handle PLA, ABS, PETG, and TPU materials with 1.75mm filament diameter compatibility. This standard diameter guarantees consistent material sourcing and cost optimization.

High-temperature extruders reaching 280°C reveal advanced filament options for specialized projects. These capabilities expand your service offerings and command premium pricing. Filament runout detection prevents material waste during large-scale production runs, protecting your profit margins on extended prints.

Quick-swap nozzle systems enable rapid shifts between different filament types and sizes. This feature minimizes downtime between projects and maximizes throughput efficiency. Your investment in thorough filament compatibility translates directly into operational flexibility and revenue diversification across multiple market segments.

Remote Monitoring Capabilities

How can you effectively manage dozens of printers without constant physical supervision? Remote monitoring capabilities provide the answer. Modern 3D printers offer Wi-Fi connectivity that lets you control print jobs from smartphones or computers. I recommend selecting printers with built-in cameras for real-time visual monitoring and time-lapse recording capabilities.

Essential monitoring features include automated alerts for filament runout, power loss, and print failures. These notifications enable immediate corrective actions before costly material waste occurs. Applications provide thorough print status updates, allowing you to adjust settings without physical access to each machine.

The most productive print farms utilize printers with robust remote monitoring systems. This technology transforms print farm management from reactive supervision to proactive optimization, maximizing your operational efficiency.

Reliability and Maintenance

When selecting 3D printers for your print farm, reliability stands as the most critical factor determining operational success. I prioritize machines with robust construction and proven track records to prevent costly downtime. Regular maintenance requirements directly impact your bottom line, so I focus on printers featuring self-cleaning nozzles and easily replaceable components that minimize service interruptions.

Power loss recovery functions are non-negotiable for farm operations. These systems automatically resume printing after outages, preventing material waste and protecting your investment. I recommend units with reliable power supplies and battery backup capabilities.

Real-time monitoring technologies enhance operational efficiency through automated alerts for filament runouts and mechanical malfunctions. Additionally, I evaluate manufacturers’ spare parts availability and support networks before purchasing, as accessible components and technical resources greatly reduce downtime when issues arise.

On a final note

I’ve provided thorough data on 3D printers that’ll maximize your print farm’s efficiency and profitability. These models offer the reliability, speed, and automation features you need for continuous operation. Consider your specific production requirements, budget constraints, and space limitations when selecting equipment. The right printer combination will streamline your workflow, reduce downtime, and increase your profit margins. Start with proven models that match your current capacity needs.