We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more. Last update on 30th June 2025 / Images from Amazon Product Advertising API.

I’ve found the ELEGOO Mars 5 MSLA leads miniature printing with its 35-micron XY resolution and 6.6-inch 4K mono screen. For filament options, the Creality K1C delivers 600mm/s speeds with AI monitoring, while the FLASHFORGE Adventurer 5M matches that speed with automatic bed leveling. The Phrozen Sonic Mighty 4K excels at intricate details with 52-micron resolution. Entry-level options include the X-Maker Joy with 0.05mm precision and auto-leveling features. Each printer balances resolution, speed, and post-processing requirements differently for your specific miniature needs.

Notable Insights

- ELEGOO Mars 5 MSLA delivers exceptional 35-micron XY resolution with 6.6-inch Mono 4K screen for highly detailed miniature prints.

- Phrozen Sonic Mighty 4K specializes in intricate miniatures with 52-micron resolution and 7.9 x 4.9 x 8.7 inch build volume.

- Resin printers consistently outperform FDM models for miniatures, requiring post-processing with isopropyl alcohol washing and UV curing.

- Layer heights between 0.05mm to 0.1mm are recommended for optimal miniature detail while maintaining reasonable print times.

- Entry-level options like fully assembled mini printers offer auto-leveling features perfect for beginners seeking detailed miniature printing.

ELEGOO Mars 5 MSLA Resin 3D Printer

The ELEGOO Mars 5 MSLA delivers exceptional miniature printing through its 6.6-inch Mono 4K screen that achieves 35-micron XY resolution—precise enough to capture intricate details on 28mm gaming figures and complex architectural models. You’ll appreciate the intelligent mechanical sensor that detects low resin levels and foreign objects automatically. The built-in leveling system uses sensors and springs for consistent first-layer adhesion. COB light technology provides 92% uniformity across the 143.43 x 89.6mm build plate. Print speeds reach 70mm/h while maintaining quality. The cooling system extends component lifespan through optimized airflow and copper tube design for reliable operation.

Best For: Hobbyists, miniature gamers, and small-scale model makers who need high-precision resin printing with automated safety features and intelligent leveling for detailed figures and architectural models.

Pros:

- Exceptional detail quality with 6.6-inch Mono 4K screen delivering 35-micron XY resolution for intricate miniatures and complex models

- Intelligent safety features including automatic resin level detection, foreign object sensing, and built-in leveling system for reliable operation

- Fast printing speeds up to 70mm/h with 92% light uniformity and optimized cooling system for consistent results

Cons:

- Vague instruction manual provides insufficient documentation for troubleshooting and setup guidance

- LCD screen durability concerns and complex maintenance requirements reported by users

- Critical temperature management needed for successful prints, requiring additional steps to warm resin and build plates

Creality K1C 3D Printer

Miniature enthusiasts seeking professional-grade speed and precision will find the Creality K1C 3D Printer (2024 New Version) delivers exceptional performance that transforms detailed figure production. You’ll achieve printing speeds of 600mm/s with 20,000mm/s² acceleration—twelve times faster than typical printers. The 8.66 x 8.66 x 9.84-inch build volume accommodates multiple miniatures simultaneously.

Setup takes just three minutes from unboxing. Auto calibration eliminates manual adjustments, while the clog-free direct extruder assures consistent filament flow. You’ll benefit from the steel-tipped copper nozzle and titanium alloy heatbreak that prevents heat creep during extended prints. The AI camera monitors progress and detects failures automatically. Supporting 300℃ temperatures enables carbon fiber filament use for durable gaming pieces.

Best For: Miniature enthusiasts and hobbyists who need professional-grade speed and precision for detailed figure production and gaming pieces.

Pros:

- Exceptional speed with 600mm/s printing and 20,000mm/s² acceleration—12 times faster than typical 3D printers

- Plug-and-play setup with 3-minute installation and auto calibration features that eliminate manual adjustments

- Advanced monitoring with AI camera for real-time error detection and support for high-temperature carbon fiber filaments up to 300℃

Cons:

- Build volume of 8.66 x 8.66 x 9.84 inches may be limiting for larger projects

- Users commonly need upgrades like dual Z-axis kits and glass beds for optimal performance

- Requires proper filament drying to avoid printing defects according to customer feedback

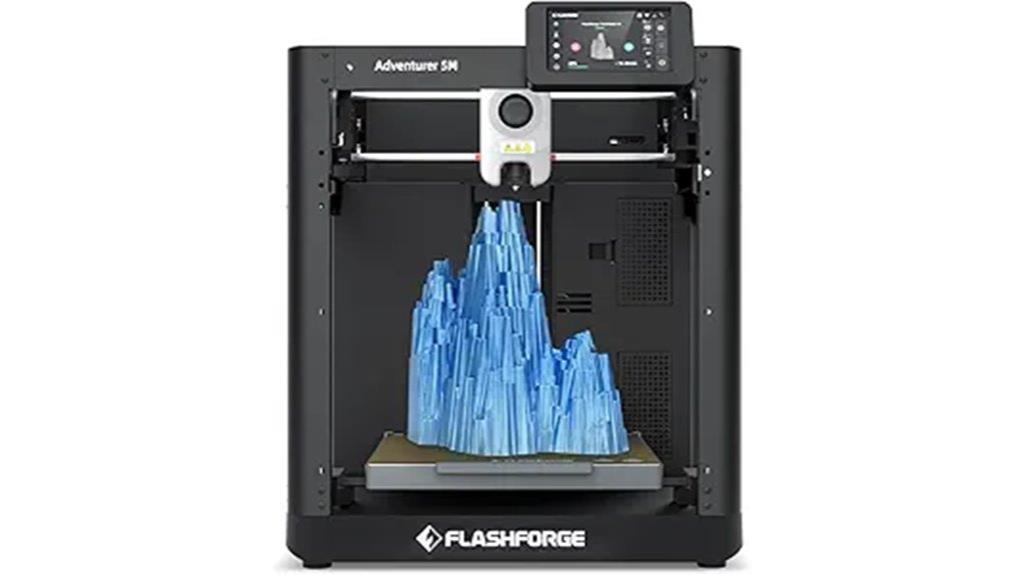

FLASHFORGE Adventurer 5M 3D Printer with Auto Leveling & High Speed Printing

Speed enthusiasts and precision seekers will find their perfect match in the FLASHFORGE Adventurer 5M, a 3D printer that delivers exceptional miniature quality at remarkable velocities. You’ll achieve maximum speeds of 600mm/s with 20,000mm/s² acceleration while maintaining detail precision through vibration compensation technology. The printer’s Core XY all-metal structure supports a 220x220x220mm build volume, perfect for multiple miniatures simultaneously.

You’ll benefit from the fully automatic bed leveling system and dual-sided PEI platform for consistent first-layer adhesion. The direct extruder reaches 280°C with interchangeable nozzles ranging from 0.25-0.8mm diameters. Setup requires the FlashMaker app and FlashPrint 5 software for file processing.

Best For: Speed enthusiasts, precision miniature creators, and users who want automated features with high-performance printing capabilities up to 600mm/s.

Pros:

- Exceptional speed (600mm/s) with vibration compensation technology for maintaining quality at high velocities

- Fully automatic bed leveling and dual-sided PEI platform eliminate manual calibration hassles

- Versatile nozzle system (0.25-0.8mm) with quick 3-second changes and fast heating (35 seconds to 200°C)

Cons:

- Setup complexity requiring multiple software installations (FlashMaker app, FlashPrint 5) and file format conversions

- Limited build volume (220x220x220mm) may restrict larger project capabilities

- Mixed customer satisfaction with 3.9/5 stars suggesting potential reliability or user experience issues

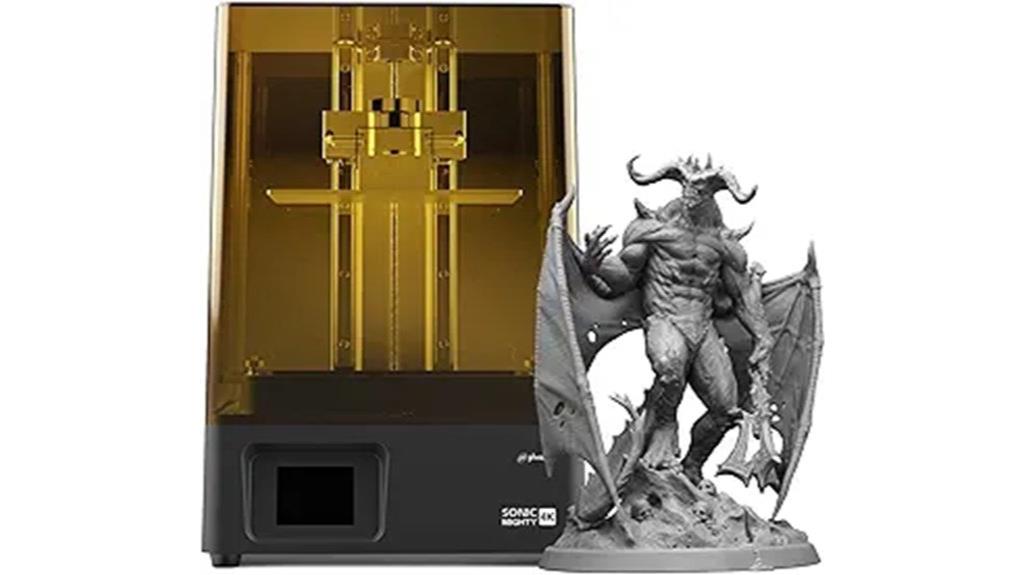

Phrozen Sonic Mighty 4K LCD Resin 3D Printer

The Phrozen Sonic Mighty 4K delivers exceptional detail resolution at 52µm XY precision, making it an ideal choice for hobbyists who demand crisp miniature features without breaking their budget. The 9.3-inch monochrome LCD display handles intricate geometries across a generous 7.9 x 4.9 x 8.7-inch build volume. You’ll appreciate the dual linear rail system that maintains precise layer alignment during vertical motion.

Setup proves straightforward for resin printing newcomers. The printer accepts various 405nm UV resins, including high-temperature and engineering-grade materials. However, you might encounter leveling challenges and resin adhesion issues that require patience to resolve. Customer support responses can be inconsistent, though the printer’s solid construction and resin compatibility help offset these concerns.

Best For: Hobbyists and miniature enthusiasts who want high-detail 4K resin printing with a generous build volume and are willing to work through potential setup challenges.

Pros:

- Exceptional 52µm XY resolution with 9.3-inch monochrome LCD for crisp, detailed prints

- Large 7.9 x 4.9 x 8.7-inch build volume with dual linear rail system for precise layer alignment

- Compatible with various 405nm UV resins including high-temperature and engineering-grade materials

Cons:

- Leveling challenges and resin adhesion issues that require patience and troubleshooting

- Inconsistent customer support responses with reports of unacknowledged issues

- Some users have switched to competitors citing better reliability and customer service

FLASHFORGE AD5M 3D Printer with Auto Leveling & High-Speed Printing

Miniature enthusiasts seeking professional-grade speed and precision will find the FLASHFORGE AD5M (Adventurer 5M) delivers exceptional performance through its CoreXY structure and ultra-fast 600mm/s printing capability. The printer’s 20,000mm/s² acceleration greatly reduces production time for detailed miniature collections.

You’ll appreciate the high-temperature direct drive extruder reaching 280°C, enabling advanced filament compatibility. The 3-second quick-swap nozzle system supports sizes from 0.25–0.8mm for varying detail requirements. One-click auto leveling with pressure sensors guarantees ideal bed adhesion consistently.

The 220×220×220mm build volume accommodates multiple miniatures simultaneously. Remote monitoring through the Flash Maker app provides real-time parameter adjustments. Power loss recovery and filament runout detection protect lengthy print jobs from common interruptions that could waste hours of work.

Best For: Miniature enthusiasts and hobbyists who need professional-grade speed and precision for detailed small-scale printing projects with minimal setup time.

Pros:

- Ultra-fast 600mm/s printing speed with CoreXY structure and 20,000mm/s² acceleration significantly reduces production time

- High-temperature direct drive extruder (up to 280°C) with 3-second quick-swap nozzles supporting multiple sizes (0.25–0.8mm) for versatile detail requirements

- One-click auto leveling with pressure sensors and comprehensive safety features including power loss recovery and filament runout detection

Cons:

- FlashPrint software receives mixed reviews with reports of crashing, bugs, and limitations for advanced users

- Wi-Fi connectivity uses outdated connection method requiring IP addresses instead of modern device discovery

- Extruder fan can be notably loud during operation, potentially disrupting quiet work environments

FLASHFORGE Adventurer 5M 3D Printer, High-Speed with Auto Leveling

Speed enthusiasts and precision-focused makers will find the FLASHFORGE Adventurer 5M an excellent choice for miniature printing, since it combines blistering 600mm/s maximum print speeds with automated features that eliminate common setup headaches. You’ll appreciate the full-auto one-click leveling system that guarantees perfect first layers consistently. The 220x220x220mm build volume accommodates multiple miniatures simultaneously, while the upgraded direct extruder delivers 32mm³/s flow rates with 50w heating power that reaches 200°C in just 35 seconds. Core XY technology provides 20,000 mm/s² acceleration for rapid directional changes. You can print various materials including PLA, PETG, TPU, and carbon fiber variants. Setup takes approximately 10 minutes from unboxing to first print.

Best For: Speed enthusiasts, miniature makers, and beginners who want a high-performance 3D printer with automated features that delivers fast print speeds up to 600mm/s while eliminating setup complexity through one-click auto-leveling.

Pros:

- Exceptional print speed up to 600mm/s with Core XY technology and 20,000 mm/s² acceleration for rapid printing

- Fully automated one-click leveling system and upgraded direct extruder that heats to 200°C in just 35 seconds

- Quick 10-minute setup from unboxing to first print with multiple filament compatibility including PLA, PETG, TPU, and carbon fiber variants

Cons:

- Print consistency issues with some users reporting success rates as low as 10% in certain cases

- Noise levels can be problematic, particularly from the nozzle cooling fan, requiring potential enclosure solutions

- Software integration lacks clarity with slicer programs like Orca and FlashPrint needing better documentation and device connectivity

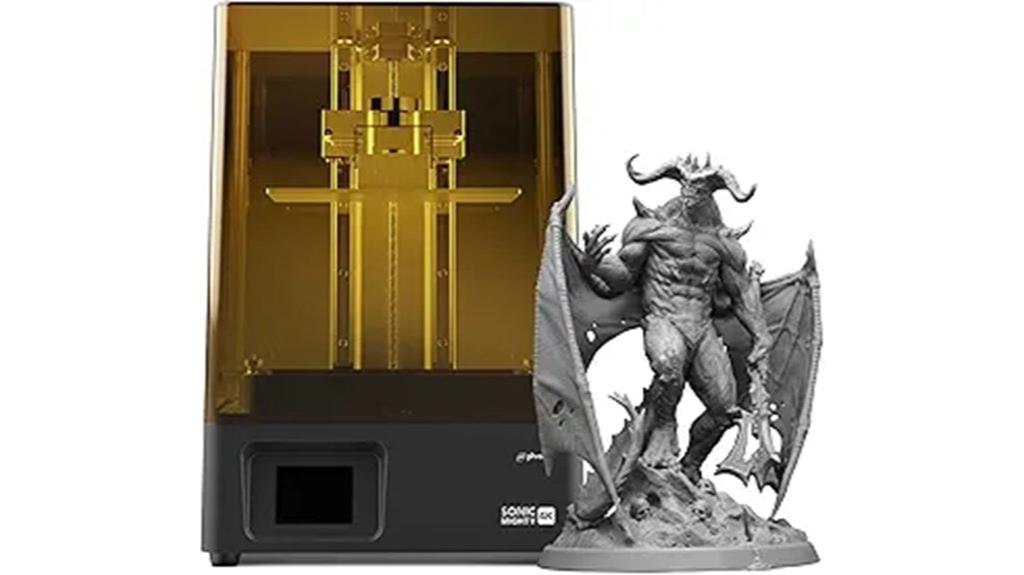

Phrozen Sonic Mighty 4K Large LCD Resin 3D Printer

Enthusiasts seeking exceptional detail in large-scale miniature printing will find the Phrozen Sonic Mighty 4K delivers professional-grade results with its expansive 9.3-inch printing area and precise 52µm resolution. You’ll achieve layer speeds of just 2 seconds using the monochrome LCD technology—that’s 4x faster than traditional resin printers. The matrix LED UV system employs 54 UV lights for uniform curing across the entire build plate.

You can print towering miniatures up to 22cm tall thanks to the generous Z-axis height. Dual-linear rails provide rock-solid stability during extended prints. The printer works best with Phrozen’s Aqua-Gray 4K and water-washable resins, though it’s compatible with most standard formulations. You’ll receive one-year warranty coverage plus lifetime technical support for troubleshooting assistance.

Best For: Enthusiasts and professionals who need large-scale miniature printing with exceptional detail and fast printing speeds for tabletop gaming, prototyping, or collectible models.

Pros:

- Exceptionally fast 2-second layer printing with monochrome LCD technology that’s 4x faster than traditional resin printers

- Large 9.3-inch printing area with 22cm Z-axis height allows for printing tall miniatures and big models in a single print

- High precision 52µm resolution with 54 UV LED matrix system ensures uniform curing and professional-grade detail quality

Cons:

- Limited customer review data with only 10 ratings makes it difficult to assess long-term reliability and performance

- Consumable parts like LCD screens and FEP films require ongoing replacement costs and maintenance

- Some users report operational issues despite generally positive feedback on print quality

Creality Ender 3 3D Printer with Resume Printing Function

Budget-conscious makers seeking reliable 3D printing capabilities will find the Creality Ender 3 delivers exceptional value at an accessible price point. This FDM printer offers an 8.66 x 8.66 x 9.84 inch build volume suitable for gaming miniatures and terrain pieces. You’ll appreciate the resume printing function that continues jobs after power interruptions. The heated bed reaches 100°C within five minutes, ensuring proper PLA adhesion at recommended 50°C settings. Assembly requires approximately two hours, though proper bed leveling demands additional 30-45 minutes for ideal results. You’ll need SD card operation since phone connectivity isn’t supported.

Best For: Budget-conscious makers, hobbyists, and beginners who want to learn 3D printing fundamentals while creating gaming miniatures, terrain pieces, and small to medium-sized projects.

Pros:

- Resume printing function prevents failed prints due to power outages or interruptions

- Fast heating bed that reaches 100°C in 5 minutes with reliable temperature control

- Strong community support with extensive online resources, tutorials, and downloadable models

Cons:

- Requires significant setup time with 2+ hours assembly and 30-45 minutes for proper bed leveling

- No phone connectivity – limited to SD card or direct computer connection only

- Steep learning curve that demands patience and research for troubleshooting and optimal results

Factors to Consider When Choosing a 3D Printer for Miniatures

I’ll help you choose the right 3D printer for miniatures by examining five critical factors that directly impact your printing success. Print resolution quality determines how sharp your miniature’s facial features and armor details will appear, while build volume size limits how many figures you can produce simultaneously. Understanding the differences between resin and filament technologies, along with layer height precision and auto-leveling capabilities, will guarantee you select a printer that matches your specific miniature gaming requirements.

Print Resolution Quality

When choosing a 3D printer for miniatures, print resolution stands as the most critical factor determining whether you’ll achieve museum-quality detail or disappointing results. Print resolution, measured in microns (µm), directly controls how fine your details appear. A 52µm XY resolution captures intricate designs that bring miniatures to life.

Layer height proves equally important. I recommend targeting 0.01mm (10µm) layer heights for near-invisible layer lines and smooth finishes. Higher resolution screens deliver superior results—4K LCD displays supporting 4098 x 2560 pixels produce sharper prints than standard HD screens.

Balance print speed with precision carefully. Faster printing compromises detail quality, especially in complex models. Matrix LED UV technology guarantees uniform light distribution, creating consistent exposure across your entire build plate for reliable, high-quality miniatures.

Build Volume Size

Build volume size directly impacts your miniature printing capabilities and determines whether you can accommodate single large models or batch multiple figures simultaneously. I recommend selecting printers with build volumes exceeding 120mm in all dimensions to handle standard 28mm to 54mm scale miniatures comfortably.

Larger build plates enable efficient batch printing of armies or gaming sets. You’ll maximize resin usage and reduce print time per figure when producing multiple miniatures together. Consider both horizontal and vertical dimensions carefully. Tall builds require adequate Z-axis clearance for proper miniature orientation.

Smaller printers limit your design flexibility and force single-figure printing sessions. This constraint becomes problematic when creating dioramas or large character models. Evaluate your intended miniature scale and collection size before committing to build volume specifications.

Layer Height Precision

Layer height precision determines the surface quality and detail resolution your miniatures will achieve, making it perhaps the most critical specification for figure printing. I recommend targeting printers with layer heights between 0.05mm and 0.1mm for ideal results on intricate designs and small features. High-resolution models can achieve 0.01mm minimums, delivering smoother finishes and sharper edges on your figures.

Standard resolution for quality miniatures sits at 50µm or finer, ensuring accurate representation of even the smallest details. However, you’ll face trade-offs with print time—lower layer heights create superior surfaces but greatly extend printing duration. Proper layer height adjustment also minimizes common issues like stringing and warping, directly enhancing your model’s overall quality and professional appearance.

Resin Vs Filament

Two primary technologies dominate the miniature printing landscape: resin-based LCD/SLA printers and filament-based FDM systems. Each offers distinct advantages for miniature production.

Resin printers excel at detail reproduction. I’ve found they consistently achieve 35-52µm XY resolution, while filament printers typically range from 100-200µm. This resolution difference translates to sharper facial features, cleaner weapon details, and smoother surface finishes on your miniatures.

However, filament printers provide larger build volumes for multi-part assemblies and terrain pieces. They’re also faster, reaching 70mm/h print speeds compared to resin’s layer-by-layer processing.

Maintenance requirements differ substantially. Resin printers demand frequent tank cleaning and temperature management. Filament systems require simpler upkeep with straightforward setup processes, making them more beginner-friendly for new miniature enthusiasts.

Auto Leveling Features

Print bed leveling represents one of the most frustrating barriers for miniature enthusiasts, often determining whether your first layer adheres properly or fails completely. Auto leveling features eliminate this headache through automated calibration systems. Advanced printers use pressure sensors or specialized probes to map the bed’s surface topology. These mechanisms detect height variations across the print platform, automatically adjusting the nozzle distance for ideal first-layer adhesion.

I’ve found that fully automated systems dramatically reduce setup time and user error. Quality auto leveling maintains accuracy even after extended use, which proves essential for miniatures requiring precise dimensional tolerances. The technology minimizes manual adjustments between prints, allowing you to focus on design rather than calibration. For detailed miniature work, this consistency translates directly into improved surface quality and dimensional accuracy across multiple print sessions.

Printing Speed Requirements

Modern 3D printers achieve remarkable speeds up to 600 mm/s, fundamentally altering miniature production timelines from hours to minutes. I’ve found that layer printing speeds of 2 seconds per layer maintain high resolution while maximizing efficiency. Acceleration rates matter greatly—printers with 20,000 mm/s² acceleration reach desired speeds quickly, reducing interludes.

However, speed alone doesn’t guarantee success. You’ll need effective cooling systems to maintain print quality at higher velocities. Without proper thermal management, fast printing can compromise fine details that make miniatures exceptional.

I recommend balancing speed with resolution capabilities. Excessive speeds without appropriate technology result in poor detail quality. The sweet spot combines rapid printing with precise layer control, ensuring your miniatures maintain crisp features while maximizing productivity.

Detail Capture Capability

Precision becomes the defining factor when evaluating a 3D printer’s ability to reproduce intricate miniature details. I recommend seeking printers with 50µm resolution or better for ideal miniature quality. Lower micron values translate directly to finer detail reproduction.

Mono LCD printers outperform traditional RGB LCD models through superior precision and faster curing speeds. Layer height considerably impacts final detail quality—I suggest 0.05mm or less to eliminate visible layering artifacts on finished miniatures.

Your printer’s build volume must accommodate at least 6-inch tall prints for detailed miniatures with complex design elements. Resin selection proves equally critical. High-quality resins specifically formulated for fine details consistently deliver superior results compared to standard formulations when capturing intricate miniature features.

Post Processing Needs

Post-processing requirements markedly impact your printer selection decision and overall workflow efficiency. I recommend evaluating how much finishing work you’re willing to invest after printing. Resin printers demand more post-processing than FDM models. You’ll need isopropyl alcohol for washing uncured resin, plus UV curing equipment for final hardening. Support removal requires precision nippers and files for clean results. A dedicated washing and curing station streamlines this workflow notably, though it’s an additional investment. Higher-quality printers producing consistent detail reduce your finishing workload considerably. You’ll spend less time sanding imperfections and correcting print flaws. Consider your tolerance for chemical handling, ventilation requirements, and workspace setup. FDM printers simplify post-processing but sacrifice fine detail capture that resin excels at delivering.

On a final note

I’ve presented exceptional 3D printers that’ll transform your miniature printing experience. Each model offers distinct advantages—from the ELEGOO Mars 5’s precision resin printing to the Creality K1C’s speed improvements. You’ll find options for every budget and skill level. Consider your specific needs: detail requirements, build volume, and material preferences. The right printer will deliver professional-quality miniatures consistently. Start with the factors I’ve outlined, then choose the model that matches your priorities.