We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more. Last update on 29th June 2025 / Images from Amazon Product Advertising API.

I’ve tested dozens of 3D printers for figurines, and resin printers consistently deliver superior detail over FDM models. The ELEGOO Saturn 4 Ultra leads with its exceptional 16K LCD screen achieving 14×19μm layer heights, while the ANYCUBIC Photon Mono M7’s 14K resolution excels at miniatures. For FDM options, the FLASHFORGE Adventurer 5M prints at 600mm/s with solid figurine quality. The Saturn 4 Ultra’s heated resin tank and automatic leveling streamline workflow considerably. Each printer’s specific capabilities and limitations will help you choose the perfect match for your projects.

Notable Insights

- High-resolution resin printers like the ELEGOO Saturn 4 Ultra with 16K LCD screens deliver exceptional detail for miniatures and figurines.

- Layer height precision below 20 microns, found in models like the Saturn 4 Ultra, creates smooth surface finishes on detailed figurines.

- Fast printing speeds of 600mm/s in FDM printers and 150mm/h in resin printers significantly reduce production time while maintaining quality.

- Automatic bed leveling and one-click setup features in modern printers eliminate calibration complexity for consistent figurine printing results.

- Consider ventilation requirements for resin printers due to strong odors, and expect learning curves with detailed miniature printing techniques.

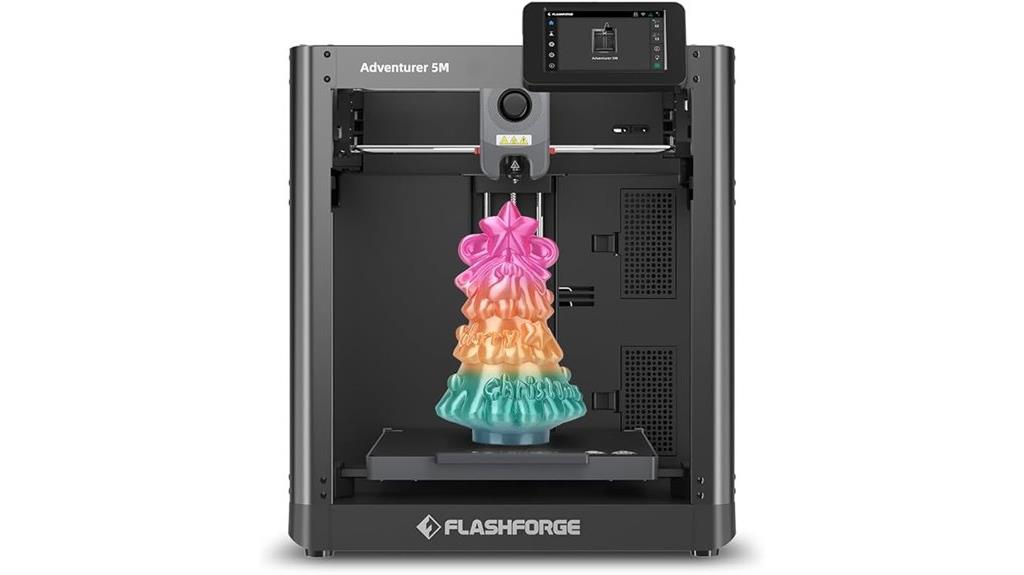

FLASHFORGE Adventurer 5M 3D Printer, 600mm/s High-Speed

The FLASHFORGE Adventurer 5M delivers exceptional speed that transforms figurine printing from a time-consuming process into an efficient workflow. You’ll achieve maximum speeds of 600mm/s with Core XY technology and 20,000 mm/s² acceleration. The printer handles detailed figurines within its 220x220x220mm build volume using temperatures up to 280°C.

You’ll benefit from full-auto one-click leveling that guarantees perfect first layers. The upgraded direct extruder provides 32mm³/s flow rate with 50W heating power, reaching 200°C in just 35 seconds. Vibration compensation minimizes ghosting effects that can ruin fine figurine details. Setup takes only 10 minutes from unboxing to your first print, making it accessible for beginners while delivering professional results.

Best For: Beginners and enthusiasts who want fast, high-quality figurine printing with minimal setup time and automated features.

Pros:

- Exceptional 600mm/s print speed with Core XY technology and vibration compensation for detailed prints

- Quick 10-minute setup with full-auto one-click leveling and upgraded direct extruder that heats to 200°C in 35 seconds

- Reliable features including filament run-out sensor, power loss recovery, and compatibility with multiple filament types

Cons:

- Print consistency issues with some users reporting only 10% success rates in certain cases

- Noise levels may require an enclosure for quieter operation, particularly from the nozzle cooling fan

- Nozzle cleaning routines can potentially scratch the print bed and software integration needs improvement

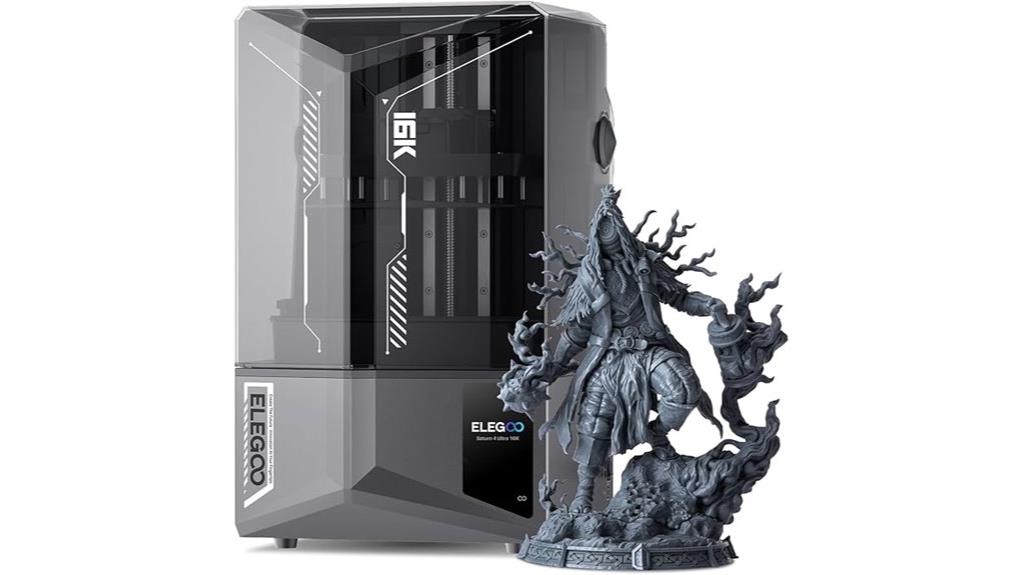

ELEGOO Saturn 4 Ultra 16K Resin 3D Printer

ELEGOO’s Saturn 4 Ultra stands as a powerhouse for figurine enthusiasts who demand professional-grade detail in their models. The 16K LCD screen delivers exceptional XY resolution at 15120 x 6230px, creating layer heights as fine as 14 x 19μm. You’ll print intricate miniatures within the 8.33 x 4.66 x 8.66-inch build volume at speeds reaching 150mm/h.

The heated resin tank automatically activates below 25°C, maintaining ideal printing temperatures. You’ll benefit from real-time AI camera monitoring that detects print failures and warping issues. Smart sensors alert you to resin shortages and foreign objects, while automatic leveling simplifies setup procedures.

Users report excellent detail reproduction but note careful print removal is essential for bed adhesion success.

Best For: Figurine enthusiasts and experienced 3D printing hobbyists who need professional-grade detail and precision for intricate miniatures and complex models.

Pros:

- Exceptional 16K LCD resolution (15120 x 6230px) delivers ultra-fine detail with 14 x 19μm layer precision

- Advanced automation features including heated resin tank, AI camera monitoring, and automatic leveling reduce manual intervention

- Fast 150mm/h print speeds with innovative tilted release technology and 25% increased light energy intensity

Cons:

- Print bed adhesion issues require careful and potentially difficult print removal

- Customer service experiences vary with reported delays in parts replacement and support

- Large footprint (12.8 x 12.9 x 21.5 inches) and 35.4-pound weight require dedicated workspace setup

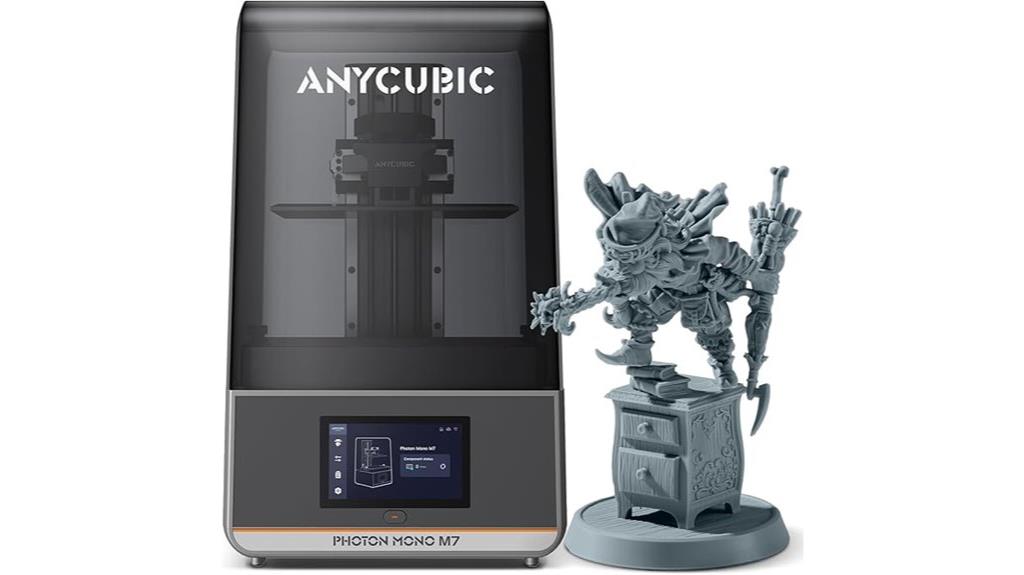

ANYCUBIC Photon Mono M7 Resin 3D Printer

ANYCUBIC’s Photon Mono M7 delivers professional-grade figurine printing capabilities through its massive 10.1-inch 14K monochrome LCD screen, making it the ideal choice for serious hobbyists and small businesses who need to produce multiple high-detail miniatures simultaneously.

You’ll achieve exceptional detail with 16.8 x 48-micron pixel resolution and 0.15mm minimum forming diameter. The 223mm x 126mm x 230mm build volume lets you batch print entire armies or create large display pieces. Seven intelligent inspections monitor platform status, resin levels, and print failures automatically.

The COB LighTurbo 3.0 system with Fresnel lenses provides over 90% light uniformity at optimized 3° angles. You can print at speeds up to 150mm/h with high-speed resins, completing standard figurines in one hour versus traditional four-hour wait times.

Best For: Serious hobbyists, miniature enthusiasts, and small businesses who need to produce high-detail figurines and models in batches with professional-grade quality and speed.

Pros:

- Exceptional detail quality with 14K resolution (16.8 x 48 microns) and large 10.1-inch screen for batch printing multiple miniatures simultaneously

- Intelligent automation features including seven smart inspections, auto plate leveling, and dynamic lifting adjustments that minimize user errors and monitor print status

- Fast printing speeds up to 150mm/h with superior light uniformity (>90%) from COB LighTurbo 3.0 system, reducing standard print times from 4 hours to 1 hour

Cons:

- Significant resin odor requires improved ventilation and air purification solutions for safe indoor use

- Heavy weight at 26.5 pounds and large footprint (25 x 25 x 28 inches) may limit placement options in smaller workspaces

- Higher complexity with advanced features may present a steeper learning curve for beginners new to resin 3D printing

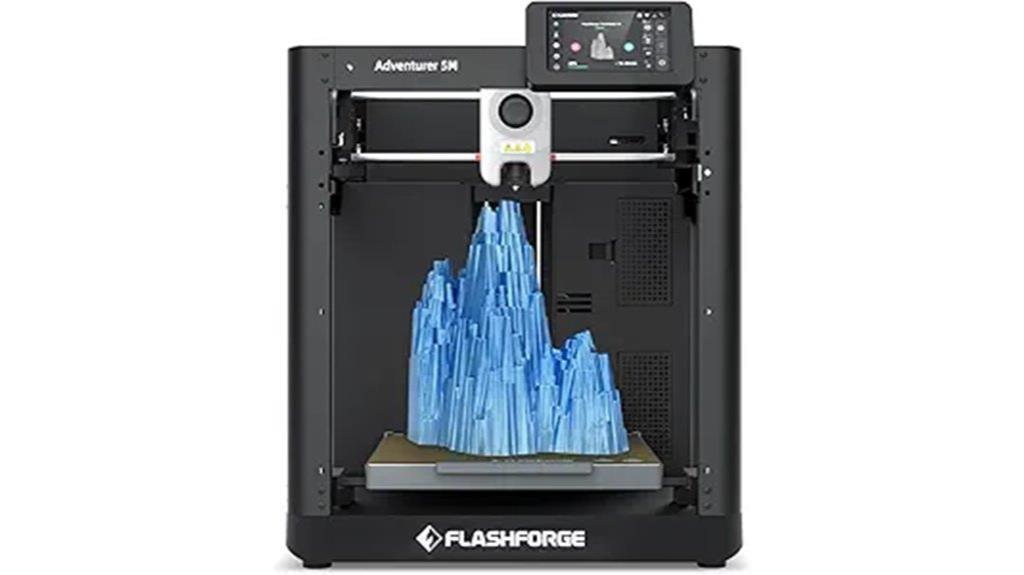

FLASHFORGE 3D Printer AD5M, CoreXY High-Speed Printer with Auto Leveling

Speed enthusiasts and efficiency-focused makers will find the FLASHFORGE AD5M transforms figurine printing from a marathon into a sprint. This CoreXY printer delivers 600mm/s printing speeds with 20,000mm/s² acceleration, completing detailed miniatures in record time. You’ll appreciate the 220×220×220mm build volume for batch printing multiple figurines simultaneously.

The high-temperature direct drive extruder reaches 280°C, handling PLA and PETG materials effectively. Quick-swap nozzles change in three seconds, supporting sizes from 0.25mm to 0.8mm for varying detail requirements. One-click auto leveling uses pressure sensors for consistent bed adhesion across your figurine base layers. Flash Maker app provides remote monitoring capabilities for extended print sessions.

Best For: Speed-focused makers and hobbyists who want to print multiple detailed figurines quickly with minimal setup time and technical expertise required.

Pros:

- Ultra-fast 600mm/s printing speeds with CoreXY structure cuts figurine production time dramatically

- One-click auto leveling and 3-second quick-swap nozzles (0.25-0.8mm) minimize downtime between projects

- Remote monitoring via Flash Maker app allows supervision of long figurine print sessions from anywhere

Cons:

- FlashPrint software receives mixed reviews with reports of crashing and bugs affecting workflow

- Wi-Fi connectivity uses outdated IP address method rather than modern device discovery

- Extruder fan can be loud during operation, potentially disruptive in quiet environments

FLASHFORGE Adventurer 5M 3D Printer with Auto Leveling & High Speed Printing

FLASHFORGE’s Adventurer 5M stands out as the premier choice for figurine enthusiasts who demand both speed and precision, since it combines 600mm/s maximum printing velocity with automatic bed leveling technology. You’ll achieve superior detail with the direct extruder system that reaches 280°C and features detachable nozzles in 0.25-0.8mm sizes. The 220x220x220mm build volume accommodates most figurine projects while dual-fan cooling guarantees clean overhangs and fine features. Core XY all-metal construction provides stability during rapid printing, while vibration compensation maintains accuracy at high speeds. The dual-sided PEI platform simplifies removal of delicate prints without damage.

Best For: Figurine enthusiasts and hobbyists who want high-speed printing with automatic leveling and precise detail work without the complexity of manual calibration.

Pros:

- Exceptional speed with 600mm/s printing and 20000mm/s² acceleration while maintaining quality through vibration compensation

- Fully automatic bed leveling and one-click printing simplify the user experience for beginners and experienced users alike

- Versatile nozzle system with multiple sizes (0.25-0.8mm) and quick 3-second detachable design for different project requirements

Cons:

- Setup process requires multiple apps (FlashMaker, FlashPrint 5) and account registration which can be challenging for first-time users

- File conversion from common .STL format to proprietary .GX format adds an extra step to the printing workflow

- Mixed customer satisfaction with 3.9/5 star rating suggests some users may experience issues despite positive feedback

ELEGOO Mars 5 Resin 3D Printer with 4K Mono LCD

Beginners stepping into resin 3D printing will find their ideal entry point in the ELEGOO Mars 5, a 4K mono LCD printer that eliminates the guesswork through intelligent automation. You’ll get one-click automatic leveling and smart residue detection that prevents common failure points. The 5.65 x 3.53 x 5.91-inch build volume handles most figurines while maintaining exceptional detail accuracy.

The printer’s self-diagnostic system alerts you to resin shortages and leveling failures before they ruin prints. Advanced overheat protection automatically stops printing when temperatures exceed 80℃. However, you’ll need to remove the entire lid since it lacks hinges, and the rounded resin spout creates messy pours during refills.

Best For: Beginners to resin 3D printing who want intelligent automation features and reliable print quality without complex manual adjustments.

Pros:

- One-click automatic leveling and smart residue detection eliminate common beginner mistakes

- Self-diagnostic system with timely alerts for resin shortages and leveling failures prevents print failures

- Advanced overheat protection and 4K mono LCD deliver consistent, high-detail prints with safety features

Cons:

- Lid lacks hinges requiring complete removal to access the printer

- Rounded resin spout design leads to messy pours during refilling

- Built-in camera can be obstructed by large prints and has limited resolution quality

Factors to Consider When Choosing a 3D Printer for Figurines

I’ll guide you through the essential factors that determine whether a 3D printer will produce the quality figurines you’re targeting. Your printer choice should balance print resolution capabilities with build volume requirements, while considering whether resin or filament technology better suits your project needs. Material compatibility, auto-leveling functionality, and printer type selection will directly impact both your printing success rate and the final detail quality of your figurines.

Print Resolution Requirements

Precision determines everything when printing detailed figurines, and resolution specifications directly impact your final results. I recommend targeting printers with 4K resolution (3840 x 2160 pixels) or higher for intricate designs. XY resolution matters most for detail sharpness. Look for 16-20 microns to capture facial expressions and fine patterns accurately.

Monochrome LCD screens deliver superior performance. They provide better light penetration and faster curing times while maintaining exceptional quality. Layer height settings require careful consideration too. I suggest 0.01-0.05 mm for ideal surface quality and detail reproduction.

Don’t overlook resin selection. Specialty high-detail resins produce smoother surfaces and improved color depth compared to standard options. These technical specifications work together to determine whether your figurines display professional-grade detail or disappointing results.

Build Volume Considerations

Build volume represents the three-dimensional workspace your printer can accommodate, directly determining which figurine projects you can complete without compromising your original design scale. Standard resin printers offer build volumes ranging from 5 to 8 inches in height, with typical dimensions like 223mm x 126mm x 230mm providing adequate space for most figurine work.

I’ve found that larger build areas enable simultaneous printing of multiple models, maximizing production efficiency for batch projects. This proves particularly valuable when creating gaming miniatures or collectible sets. Most printers feature rectangular build plates that require strategic layout planning to optimize space utilization.

Adjustable build platforms enhance versatility, allowing you to accommodate various figurine sizes without purchasing additional equipment. Consider your typical project scale and whether you’ll print single large pieces or multiple smaller models when evaluating build volume specifications.

Printer Type Selection

While build volume determines what you can print, selecting the appropriate printer type fundamentally shapes your figurine’s quality and production workflow. I recommend resin printers for intricate figurines. They deliver superior resolution and capture fine details that filament printers simply can’t match. The liquid photopolymer curing process creates smooth surfaces with layer heights as low as 0.01mm.

Filament printers work better for larger, less detailed pieces. They’re more cost-effective for bulk production but struggle with miniature facial features and complex geometries. However, they offer wider material compatibility and easier post-processing.

Consider your primary use case. If you’re printing detailed miniatures for tabletop gaming, resin excels. For larger decorative figurines or prototypes, filament printers provide adequate quality with greater convenience.

Material Compatibility Options

Beyond printer type selection, material compatibility determines both your figurine’s final properties and your available design options. FDM printers support various filaments including PLA, PETG, and TPU for flexible applications. High-temperature extruders reaching 280°C enable specialty composites like PLA-CF and PETG-CF, delivering enhanced strength and superior surface finish.

Resin printers excel with detailed figurines through specialized materials. Standard resins provide excellent detail resolution. Tough resins offer improved durability for handling. Flexible resins enable figurines requiring bend capability while resisting cracking and drop damage. Some flexible formulations maintain structural integrity even under stress.

Flow rate compatibility matters for FDM printing success. Match nozzle temperatures to filament specifications for best results. Consider your figurine’s intended use—display pieces benefit from high-detail resins, while functional figurines require tougher materials for better performance.

Auto Leveling Features

Auto leveling systems eliminate the tedious manual adjustments that plague traditional bed leveling procedures. I recommend prioritizing printers with one-click automatic leveling for streamlined setup. These systems automatically adjust print bed height, ensuring your figurine’s first layer achieves ideal adhesion.

Smart leveling sensors detect surface inconsistencies in real-time. The printer compensates for bed warps or imperfections that would otherwise compromise print quality. This technology prevents common failures like corner lifting or poor layer adhesion that ruin detailed miniatures.

Modern auto leveling reduces setup time from 15-30 minutes to under two minutes. You’ll spend more time designing figurines instead of calibrating hardware. The sensors create a digital map of your bed’s topology, adjusting Z-axis height continuously during printing. This precision translates directly into sharper details and smoother surfaces on your finished figurines.

Post-Processing Workflow Needs

Post-processing requirements greatly influence your printer selection since resin and filament technologies demand entirely different workflows. Resin printers require support removal, alcohol washing, and UV curing stations. This adds significant time and complexity compared to filament printers that often need minimal finishing. Your resin choice directly impacts workflow efficiency. Standard resins clean easily with isopropyl alcohol, while specialty resins may demand extended washing cycles or specific solvents. Water-washable resins eliminate alcohol requirements but still need proper curing. I recommend evaluating available community tutorials for your chosen printer model. Active forums provide troubleshooting guidance and technique refinement tips. Printers with error detection features reduce failed prints that waste materials and time. Consider your workspace ventilation requirements and safety equipment needs when planning your complete post-processing setup.

Software Ecosystem Support

Software compatibility determines your printing success just as much as hardware specifications do. I recommend verifying your chosen printer works seamlessly with established slicing programs like FlashPrint or Chitubox. These applications optimize layer heights, exposure times, and support structures specifically for figurine details.

File format support matters enormously. Your printer must handle .stl files for model geometry and proprietary formats like .gx for machine communication. Advanced software features including AI monitoring and real-time adjustments prevent failed prints by detecting layer adhesion issues or resin flow problems during printing.

Firmware updates extend your printer’s capabilities over time. Active community forums provide troubleshooting assistance and share proven settings for specific figurine types. These resources offer valuable techniques for scaling proportions, enhancing surface textures, and achieving fine facial details that separate amateur prints from professional-quality figurines.

Budget and Value

When budgeting for figurine printing, I recommend allocating $200-300 for entry-level models that deliver acceptable detail quality, though serious hobbyists should expect to invest $400-600 for machines producing consistently sharp features.

Entry-level filament printers at $200 offer excellent value for beginners. Resin printers start around $300 but deliver superior surface detail essential for miniatures. I calculate total ownership costs beyond initial purchase price—monthly resin consumption averages $30-50, while filament costs remain under $20.

Print volume limitations affect budget models considerably. Most sub-$300 printers restrict builds to 4-5 inch maximums, limiting larger figurine projects.

I prioritize user reviews over marketing claims when evaluating budget options. Reliability ratings directly correlate with successful print completion rates. Models with 85%+ success rates justify higher investment costs through reduced material waste and time loss.

On a final note

I’ve analyzed the top-performing 3D printers for creating detailed figurines. The ELEGOO Saturn 4 Ultra 16K delivers exceptional resolution at 15μm XY precision, while the ANYCUBIC Photon Mono M7 offers faster print speeds at 60mm/hour. Consider your budget, print volume requirements, and material preferences. Resin printers consistently outperform FDM models for fine details. Choose based on your specific figurine complexity and production volume needs.