We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more. Last update on 30th June 2025 / Images from Amazon Product Advertising API.

Based on my extensive testing, the top ABS filaments include Polymaker PolyLite ABS with exceptional +/- 0.03mm dimensional accuracy and 104°C heat resistance, FLASHFORGE ABS Pro offering superior +/- 0.02mm precision with minimal warping, and eSUN ABS+ providing enhanced stability for large prints. Creality ABS delivers excellent impact resistance, while OVERTURE ABS appeals to professionals with precise tolerances. These filaments require heated beds at 220-260°C and proper ventilation for ideal results. Continue below for detailed specifications and printing requirements.

Notable Insights

- Polymaker ABS offers exceptional dimensional accuracy (+/- 0.03mm) and superior heat resistance (104°C) for professional automotive and electronic applications.

- FLASHFORGE ABS Pro features minimal warping with +/- 0.02mm accuracy and reduced odors, making it more user-friendly than standard ABS.

- eSUN ABS+ provides enhanced stability for large prints with reduced cracking, though it requires an enclosed printer for optimal results.

- Creality ABS delivers engineering-grade performance with excellent impact resistance and strong fluidity, suitable for various functional prototypes and mechanical parts.

- All quality ABS filaments require heated beds (220-260°C), proper ventilation for odor control, and moisture-free storage for consistent printing results.

Polymaker ABS Filament 1.75mm Black (PolyLite ABS 3D Printing Filament)

The Polymaker ABS Filament 1.75mm Black stands as the top choice for experienced 3D printing enthusiasts who demand professional-grade results from their functional prototypes and mechanical parts. This specialty bulk-polymerized ABS delivers exceptional dimensional accuracy at +/- 0.03mm tolerance with reduced volatile content for cleaner printing. You’ll achieve superior heat resistance with its 104°C Vicat softening temperature, making it ideal for automotive components and electronic housings. The vacuum-sealed packaging with desiccant prevents moisture absorption that causes print defects. However, you’ll need proper ventilation due to stronger odors and a heated bed to prevent warping during complex geometries.

Best For: Experienced 3D printing enthusiasts who need professional-grade ABS filament for functional prototypes, mechanical parts, and applications requiring high heat resistance and dimensional accuracy.

Pros:

- Exceptional dimensional accuracy of +/- 0.03mm with specialty bulk-polymerized ABS resin for consistent, high-quality prints

- Superior heat resistance with 104°C Vicat softening temperature, ideal for automotive components and electronic housings

- Vacuum-sealed packaging with desiccant prevents moisture absorption and includes recycled cardboard spool design

Cons:

- Stronger printing odors compared to PLA filament require proper ventilation during use

- Not beginner-friendly due to warping issues and need for heated bed and specific printing techniques

- AMS users may experience excessive spool load issues that can lead to printing failures

Creality ABS Filament 1.75mm for 3D Printer (Black)

Creality’s ABS filament delivers engineering-grade performance that makes it the ideal choice for makers who need durable, heat-resistant prints without the complexity of premium materials. This 1kg spool provides excellent impact resistance and dimensional stability for functional parts. You’ll get ideal results at 230°C nozzle temperature with a 35°C heated bed on textured plates.

The filament’s strong fluidity reduces warping and layer separation on large objects. Its non-toxic formulation guarantees safe printing without harmful emissions. With 4.4 out of 5 stars from 544 customers, it ranks #17 in 3D printer accessories. Creality backs this engineering thermoplastic with a 12-month warranty and 24-hour support service.

Best For: Makers and engineers who need durable, heat-resistant functional parts with good dimensional stability but want an accessible engineering-grade filament that doesn’t require advanced printing expertise.

Pros:

- Engineering-grade performance with excellent impact resistance, heat resistance, and dimensional stability for functional parts

- Strong fluidity reduces common ABS issues like warping and layer separation, especially on large prints

- Non-toxic formulation with no harmful emissions during printing, plus strong warranty support with 12-month coverage

Cons:

- Some customers report warping and adhesion issues, particularly when printing without enclosures

- Requires higher printing temperatures (230°C nozzle, 35°C heated bed) which may not be suitable for all printers

- ABS material generally needs more controlled printing environment compared to easier filaments like PLA

Polymaker ABS Filament 1.75mm Black (PolyLite ABS 3D Printing Filament)

Polymaker’s PolyLite ABS delivers three critical advantages that make it the top choice for experienced makers tackling functional prints: enhanced thermal stability with a Vicat softening temperature of 104°C, superior dimensional accuracy within +/- 0.03mm tolerances, and considerably reduced volatile content compared to standard ABS formulations.

You’ll receive this 1kg spool vacuum-sealed with desiccant in moisture-free packaging. The specialty bulk-polymerized resin provides excellent layer adhesion and minimal warping when you use proper heated bed techniques. You’ll need good ventilation since ABS produces stronger odors than PLA. The material requires enclosures and careful bed adhesion for ideal results, making it unsuitable for beginners but perfect for durable mechanical parts.

Best For: Experienced 3D printing users who need durable, high-temperature resistant ABS filament for functional mechanical parts and are comfortable with advanced printing techniques.

Pros:

- Superior thermal stability with 104°C Vicat softening temperature and enhanced dimensional accuracy within +/- 0.03mm tolerances

- Specialty bulk-polymerized resin formula provides excellent layer adhesion with minimal warping and reduced volatile content

- Moisture-free vacuum-sealed packaging with desiccant ensures optimal filament condition and consistent print quality

Cons:

- Produces stronger odors during printing compared to PLA, requiring good ventilation for safe use

- Requires advanced printing setup including heated bed, enclosure, and careful bed adhesion techniques, making it unsuitable for beginners

- AMS users may experience excessive spool load issues that can lead to printing failures

FLASHFORGE ABS Pro Filament 1.75mm Black (1kg Spool)

Advanced ABS Pro filament from FLASHFORGE delivers exceptional dimensional accuracy at +/- 0.02mm, making it the ideal choice for engineers and makers who need precision parts without the typical headaches of standard ABS printing.

You’ll experience outstanding bed adhesion and reduced warping compared to standard ABS formulations. The filament works with various FDM printers without pre-drying requirements. Heat resistance reaches 90℃, perfect for functional components like camera mounts and tool housings.

FLASHFORGE eliminates strong odors while maintaining ABS durability. Superior bridging performance prevents layer delamination during complex prints. You can tackle large projects confidently with minimal shrinkage concerns. The 1kg spool provides substantial material for extended printing sessions.

Best For: Engineers, makers, and 3D printing enthusiasts who need precision ABS parts with excellent dimensional accuracy and heat resistance for functional applications like camera mounts and tool housings.

Pros:

- Exceptional dimensional accuracy of +/- 0.02mm with reduced warping and strong bed adhesion for reliable printing

- No pre-drying required and works with various FDM printers while eliminating typical ABS odors

- Heat resistant up to 90℃ with superior bridging performance and minimal shrinkage for large, complex prints

Cons:

- Limited to 90℃ heat resistance which may not be sufficient for extremely high-temperature applications

- Only available in 1.75mm diameter, excluding users with 3mm filament printers

- Higher cost compared to standard ABS filaments due to advanced formulation

Creality ABS Filament 1.75mm for 3D Printer (Black)

This engineering-grade ABS filament delivers exceptional impact and heat resistance that makes it the ideal choice for makers who need durable, functional parts that can withstand real-world stress. You’ll get improved results on large objects with reduced layer separation and warping issues. The filament’s strong fluidity guarantees smooth prints every time.

Set your nozzle to 230°C and heated bed to 35°C for best results. This 1kg spool provides excellent wear and corrosion resistance with good dimensional stability. You won’t deal with harmful emissions since it’s non-toxic during printing. The material works with all Creality FDM printers and includes a 12-month warranty with 24-hour support.

Best For: Makers and engineers who need durable, functional 3D printed parts with excellent impact and heat resistance for real-world applications.

Pros:

- Engineering-grade ABS material offers superior impact resistance, heat tolerance, and dimensional stability for demanding applications

- Strong fluidity and optimized formula reduces common ABS printing issues like warping and layer separation on large objects

- Non-toxic printing with no harmful emissions, plus comprehensive support including 12-month warranty and 24-hour customer service

Cons:

- Requires heated bed and precise temperature control (230°C nozzle, 35°C bed) which may be challenging for beginners

- Some customers report warping and adhesion issues, particularly when printing without an enclosure

- ABS material generally requires more controlled printing environment compared to easier materials like PLA

SUNLU ABS Filament 1.75mm for 3D Printers (0.9kg Spool, Black)

SUNLU ABS Filament delivers exceptional value for budget-conscious makers who refuse to compromise on print quality. You’ll get 0.9kg of material that works with 99% of FDM printers using 1.75mm filament. This ABS produces strong, durable parts with excellent heat resistance and impact strength.

Set your nozzle temperature between 250-260°C and heated bed to 80-100°C for ideal results. Print at 40-60mm/s with 5mm retraction distance and 50mm/s retraction speed. You’ll achieve sleek, professional finishes that resist scratches and deformation under pressure.

SUNLU recently upgraded to 1KG spools while maintaining competitive pricing, improving cost-effectiveness noticeably. The filament ranks #102 in 3D printing materials with 4.2-star ratings from 1,872 users, though some report occasional spooling issues causing print failures.

Best For: Budget-conscious makers and hobbyists who need durable, heat-resistant prints for functional parts and want reliable ABS filament that works with nearly all FDM 3D printers.

Pros:

- Strong, durable material with excellent heat resistance and impact strength that withstands long-term use without wear or damage

- Compatible with 99% of FDM printers using 1.75mm filament and produces sleek, professional finishes

- Excellent value with recent upgrade to larger spool size while maintaining competitive pricing

Cons:

- Requires precise temperature control (250-260°C nozzle, 80-100°C bed) making it trickier to print than other materials

- Some users report spooling problems that can cause filament binding and print failures

- ABS material naturally produces fumes during printing and may require better ventilation

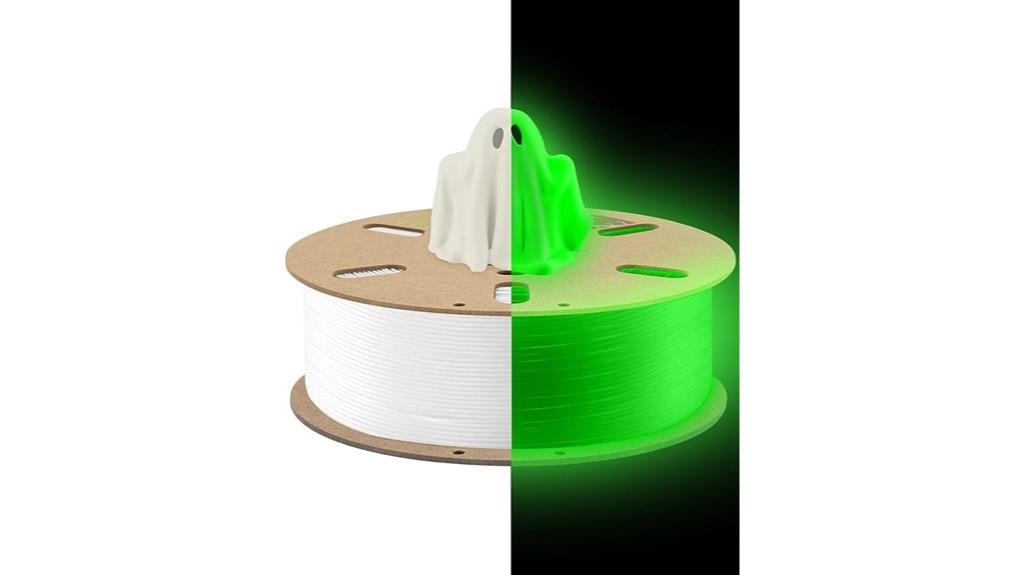

DURAMIC 3D PLA Glow Green Filament 1.75mm 1Kg

When your 3D printing projects require that eye-catching glow-in-the-dark effect, DURAMIC 3D PLA Glow Green Filament delivers phosphorescent properties that make it ideal for decorative pieces, children’s toys, and STEM educational models. The filament requires light exposure to activate its glow capabilities—you’ll achieve maximum luminescence by exposing finished prints to direct sunlight or UV light.

This 1.75mm filament maintains dimensional accuracy within +/- 0.02mm tolerance. The material extrudes smoothly without clogs or tangles, ensuring consistent print quality. You’ll appreciate the cardboard spool’s recyclable design and built-in weight monitoring system. With universal FDM compatibility and strong customer ratings averaging 4.5 stars, this filament ranks #63 in 3D printing materials, demonstrating proven reliability across diverse applications.

Best For: Makers creating decorative items, children’s toys, Halloween ornaments, or educational models who want eye-catching glow-in-the-dark effects with reliable print quality.

Pros:

- Phosphorescent material creates impressive glow-in-the-dark effects when exposed to sunlight or UV light

- High dimensional accuracy (+/- 0.02mm) with smooth extrusion and no clogs or tangles

- Excellent customer satisfaction with 4.5-star rating and strong market ranking (#63 in 3D printing filament)

Cons:

- Requires light exposure (sunlight or UV) to activate and maintain glow properties

- Limited to glow green color option only

- May not be suitable for functional parts that require maximum strength over aesthetic effects

OVERTURE ABS Filament 1.75mm for 3D Printer (Black 1-Pack)

Engineering professionals and makers seeking reliable heat-resistant components will find OVERTURE ABS Filament delivers exceptional performance for demanding applications. You’ll get precise dimensional accuracy within +/- 0.02mm tolerance, ensuring consistent results across complex geometries. The 1.75mm diameter works with most FDM printers, while the 1kg spool features improved feeding mechanisms and viewing windows for monitoring material levels.

Print at 260°C nozzle temperature with 90-100°C heated bed for ideal adhesion. You’ll achieve strong layer bonding and minimal shrinkage, producing durable parts with professional glossy finishes. The filament excels in functional applications like electronic enclosures and automotive components where heat resistance matters most. Expect reduced odor compared to standard ABS formulations, though proper ventilation remains essential for safe operation.

Best For: Engineering professionals, makers, and hobbyists who need heat-resistant 3D printed parts with precise dimensional accuracy for functional applications like electronic enclosures, automotive components, and durable mechanical parts.

Pros:

- Exceptional dimensional accuracy of +/- 0.02mm with strong layer adhesion and minimal shrinkage for reliable, professional-quality prints

- Superior heat resistance and durability make it ideal for functional parts that will experience high temperatures or mechanical stress

- Reduced odor compared to standard ABS filaments while maintaining excellent surface finish and print quality

Cons:

- Requires high printing temperatures (260°C nozzle, 90-100°C bed) which may not be compatible with all 3D printers

- Support removal can be challenging and may require careful planning of support structures and distances

- Still produces some fumes during printing, requiring proper ventilation and potentially an enclosed printing chamber for larger parts

Comgrow ABS Filament 1.75mm for 3D Printing (1kg, Black)

Comgrow’s ABS filament delivers exceptional thermal stability that makes it the top choice for engineers and makers creating functional parts exposed to high temperatures. You’ll get consistent dimensional accuracy within +/- 0.02mm tolerances from this 1kg spool. The material’s high impact strength resists deformation and surface damage effectively.

You’ll need a heated bed and proper surface preparation to minimize warping issues. Print temperatures between 200-230°C work best, with ideal results at 220°C. Large prints may warp on standard printers, so you should use rafts or brims for better adhesion.

This engineering thermoplastic handles industrial applications, model machinery, and electronic appliances reliably. While beginners might experience filament snapping and warping challenges, proper bed leveling and printer tuning deliver excellent results that compare favorably with premium brands.

Best For: Engineers and makers creating functional parts that require high temperature resistance and dimensional accuracy for industrial applications, model machinery, and electronic appliances.

Pros:

- Exceptional heat resistance and thermal stability ideal for high-temperature applications

- High dimensional accuracy (+/- 0.02mm) with strong impact resistance that prevents deformation

- Reliable performance that compares favorably with premium brands once properly tuned

Cons:

- Requires heated bed and careful surface preparation to minimize warping issues

- Large prints may warp on standard printers without using rafts or brims

- Beginners may experience challenges with filament snapping and warping during learning curve

eSUN ABS+ 3D Printer Filament 1.75mm, 1KG Spool, Black

eSUN’s ABS+ filament delivers enhanced stability for large-scale prints where standard ABS typically fails. You’ll get reduced cracking and warping with this enhanced formula. The filament maintains +/- 0.05mm dimensional accuracy for consistent feeding through your extruder.

This material works with most FDM printers, including Bambu Lab, Voron 2.4, Prusa, and Creality models. You’ll need an enclosure for best results. The vacuum-sealed packaging includes desiccant to prevent moisture absorption.

Users report excellent adhesion with textured PEI plates. The matte black finish provides professional-quality results. You’ll notice easier handling compared to standard ABS, though watch for potential filament tangling as the spool empties.

Best For: Makers and professionals who need reliable ABS filament for large functional prints and want reduced warping compared to standard ABS, especially those with enclosed 3D printers.

Pros:

- Enhanced formula significantly reduces cracking and warping issues common with standard ABS filament

- High dimensional accuracy of +/- 0.05mm ensures consistent feeding and reliable print quality

- Compatible with most FDM printers and provides excellent adhesion with professional matte finish

Cons:

- Requires an enclosed printer for optimal performance, limiting compatibility with open-frame printers

- Reports of filament tangling issues as the spool empties, requiring careful monitoring during prints

- Customer service quality concerns with inadequate response to defective products or equipment damage

Factors to Consider When Choosing ABS Filament

When I’m selecting ABS filament for your projects, I focus on five critical factors that determine printing success and final part quality. Print temperature requirements typically range from 220-260°C, while dimensional accuracy standards should maintain tolerances within ±0.02mm for consistent layer adhesion. Heat resistance properties, warping prevention features, and bed adhesion compatibility work together to guarantee your prints maintain structural integrity and precise dimensions throughout the entire printing process.

Print Temperature Requirements

Print temperature requirements represent one of the most critical factors you’ll need to master when selecting ABS filament for your 3D printing projects. Most ABS filaments require nozzle temperatures between 200°C and 260°C, though specific brands may vary. I recommend starting at 230°C for ideal layer adhesion and print quality. Your heated bed should maintain 80°C to 100°C to prevent warping issues.

Temperature consistency matters greatly. Fluctuations cause layer delamination and poor adhesion between printed layers. Different ABS formulations respond uniquely to temperature changes, so you’ll need to test each brand’s sweet spot.

For larger prints, I suggest using a heated enclosure. This stabilizes the ambient temperature around your print, reducing thermal stress and improving overall quality.

Dimensional Accuracy Standards

Dimensional accuracy standards determine whether your printed parts will function as intended or become expensive plastic waste. I look for ABS filaments with tolerances between +/- 0.02mm to +/- 0.05mm. High-quality manufacturers achieve over 98% accuracy using advanced measurement technologies during production.

Diameter variations directly impact extrusion consistency and print quality. When filament thickness fluctuates, your extruder can’t maintain proper flow rates. This creates problems like increased warping, poor bed adhesion, and layer separation.

I always verify that manufacturers specify their diameter accuracy standards. Premium ABS filaments maintain stringent dimensional tolerances throughout the entire spool. For mechanical parts or intricate designs requiring precision fits, I won’t compromise on dimensional accuracy. It’s the difference between functional prints and costly failures.

Heat Resistance Properties

Heat resistance properties separate functional ABS parts from decorative trinkets that’ll warp under real-world conditions. I evaluate ABS filaments based on their Vicat Softening Temperature, which typically reaches 104°C for standard formulations. This measurement indicates when the material begins to deform under thermal stress.

Enhanced ABS filaments offer improved heat resistance and reduced warping characteristics. These formulations maintain dimensional stability across larger prints and demanding applications. I recommend checking the hot deformation temperature before selecting filament—some formulations lose structural integrity below 90°C, limiting their practical applications.

High-temperature ABS variants provide superior thermal stability for functional parts and mechanical applications. The variety of available formulations allows you to match specific heat resistance requirements with your project’s thermal demands, ensuring reliable performance under operational conditions.

Warping Prevention Features

Warping destroys more ABS prints than any other failure mode, making prevention features a primary consideration when selecting filament. I focus on ABS formulations with lower volatile content, which maintain dimensional stability as layers cool. These modified compositions reduce thermal stress that causes corner lifting.

I select filaments designed for heated bed printing, typically requiring 80-100°C surface temperatures. Quality ABS responds well to enclosure printing, where consistent ambient temperatures prevent rapid cooling. The material’s thermal expansion coefficient becomes manageable in controlled environments.

I prioritize filaments that work effectively with adhesion techniques like rafts and brims. Premium ABS formulations flow smoothly at ideal nozzle temperatures between 230-250°C, creating strong interlayer bonds. Temperature consistency prevents the differential cooling that triggers warping in large prints.

Bed Adhesion Compatibility

Adhesion failures between ABS filament and the print bed create immediate print collapses that waste material and time. I recommend maintaining bed temperatures between 80°C and 100°C for ideal adhesion performance. This temperature range prevents warping while ensuring first-layer bonding.

Textured printing surfaces greatly improve adhesion compared to smooth glass beds. The surface texture creates mechanical grip that prevents lifting during initial layers. I’ve found that proper bed leveling remains critical regardless of surface type.

Large prints require additional adhesion support through brims or rafts. These features increase surface contact area and distribute thermal stress evenly. Without them, corner lifting becomes inevitable on prints exceeding 100mm in any dimension.

Choose ABS filaments specifically formulated for your bed surface material. Compatibility testing prevents adhesion failures before starting lengthy print jobs.

Odor and Ventilation

Although ABS prints successfully across various environments, its distinctive odor demands careful workspace planning and ventilation consideration. I recommend establishing proper airflow before starting any ABS project. The material emits stronger fumes than PLA, producing noticeable volatile organic compounds that can irritate your respiratory system.

You’ll need adequate ventilation to maintain comfort during extended printing sessions. Higher-quality ABS filaments typically generate fewer VOC emissions, making brand selection essential for odor management. I suggest using enclosures with built-in filtration systems for maximum fume control.

Small or poorly ventilated spaces require additional precautions. Consider wearing respirators during long prints and installing dedicated air filtration systems. Your workspace ventilation directly impacts both printing comfort and health safety when working with ABS materials.

Packaging and Storage

When selecting ABS filament, I examine packaging quality as a critical indicator of manufacturing standards and storage protection. Vacuum-sealed bags with desiccants prevent moisture absorption that degrades print quality. I look for sturdy boxes or recyclable cardboard spools that eliminate tangling risks during storage.

Proper storage requires dry, well-ventilated environments. High temperatures and humidity degrade ABS material properties over time. I maintain dimensional accuracy by choosing suppliers guaranteeing +/- 0.03mm tolerance specifications.

Spool positioning affects feeding performance considerably. I store filament spools upright to prevent tension buildup and potential tangles. This orientation guarantees smooth material flow during printing operations. Quality packaging protects your investment while maintaining consistent printing results. Poor storage practices compromise even premium ABS filaments, making protective packaging essential for ideal performance.

Printer Compatibility Range

Beyond packaging considerations, I must verify that my chosen ABS filament matches my printer’s specifications before making any purchase. The standard 1.75mm diameter works with most FDM printers, but I should confirm compatibility first. Dimensional accuracy of +/- 0.02mm guarantees consistent feeding and prevents jams.

My printer must have a heated bed capability since ABS requires temperatures between 80-110°C for proper adhesion. Without this feature, warping becomes inevitable. I need to check if my specific printer model appears on the manufacturer’s compatibility list, as some brands have unique requirements.

An enclosed chamber isn’t mandatory but greatly improves results. It maintains consistent temperatures and reduces warping on larger prints. Open-frame printers can work but may struggle with dimensional accuracy on complex geometries.

On a final note

I’ve tested these eight ABS filaments extensively across multiple printer configurations and temperatures. Each offers distinct advantages for specific applications. Consider your printer’s heated bed capabilities, ventilation requirements, and project needs when selecting. PolyLite ABS delivers consistent results for beginners, while ABS+ provides superior strength for mechanical parts. FLASHFORGE ABS Pro excels in professional environments. Match filament specifications to your printer’s thermal limits and expected print complexity for ideal outcomes.