We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more. Last update on 30th June 2025 / Images from Amazon Product Advertising API.

When selecting ultrasonic cleaners for resin prints, I recommend focusing on 3-7 liter capacity units with 40kHz frequency for ideal cleaning efficiency. The CREWORKS 3.2L and 15L models offer excellent temperature control (70-175°F) and digital timers vital for preventing damage to delicate features. Professional-grade options like the W230 and DK SONIC 700ML provide stainless steel construction that resists cleaning agent corrosion. Consider tank size, build plate compatibility, and drainage systems when choosing your model, as the following detailed analysis reveals significant performance differences.

Notable Insights

- Choose cleaners with 3-7 liter capacity and 40kHz frequency for optimal cleaning of resin prints without damaging delicate details.

- Look for adjustable temperature controls (70°F-175°F) and timer settings (0-30 minutes) to customize cleaning based on contamination levels.

- Select models with stainless steel construction and proper drainage systems to handle various cleaning solutions safely and efficiently.

- Consider build plate compatibility and tank design that accommodates different printer sizes and allows easy monitoring of cleaning progress.

- Professional-grade models offer larger capacities and higher wattage for cleaning multiple prints, while compact options work well for smaller items.

W230 Cleaner for Ultrasonic 3D Resin

The W230 Cleaner for Ultrasonic 3D Resin stands out as the best choice for users who prioritize cleaning capacity and compatibility with GKTwo printers. This 7-liter ultrasonic cleaner delivers 40KHz high-frequency vibration for thorough resin removal. You’ll appreciate its corrosion-resistant construction and clamshell design that outperforms plastic alternatives.

The unit measures 17 x 10 x 15 inches and weighs 20.9 pounds. You can wash parts using the specialized GKTwo build plate slot or the included mesh basket for direct model cleaning. The LED touch screen lets you set cleaning cycles from 0-10 minutes, with 3 minutes being ideal. A built-in draining port simplifies fluid changes without mess.

Best For: Users who need a high-capacity ultrasonic cleaner for GKTwo 3D printers and want durable, corrosion-resistant construction with specialized cleaning options.

Pros:

- Large 7-liter capacity with 40KHz ultrasonic technology provides thorough and efficient resin removal

- Dual cleaning methods with specialized GKTwo build plate slot and mesh basket for versatile part cleaning

- Corrosion-resistant construction with clamshell design and draining port offers durability and convenient maintenance

Cons:

- Some users report issues with leaks and concerns about long-term reliability

- Lacks advanced features like built-in heater and adjustable frequency settings found in competitors

- Higher price point compared to alternatives that offer similar functionality with more features

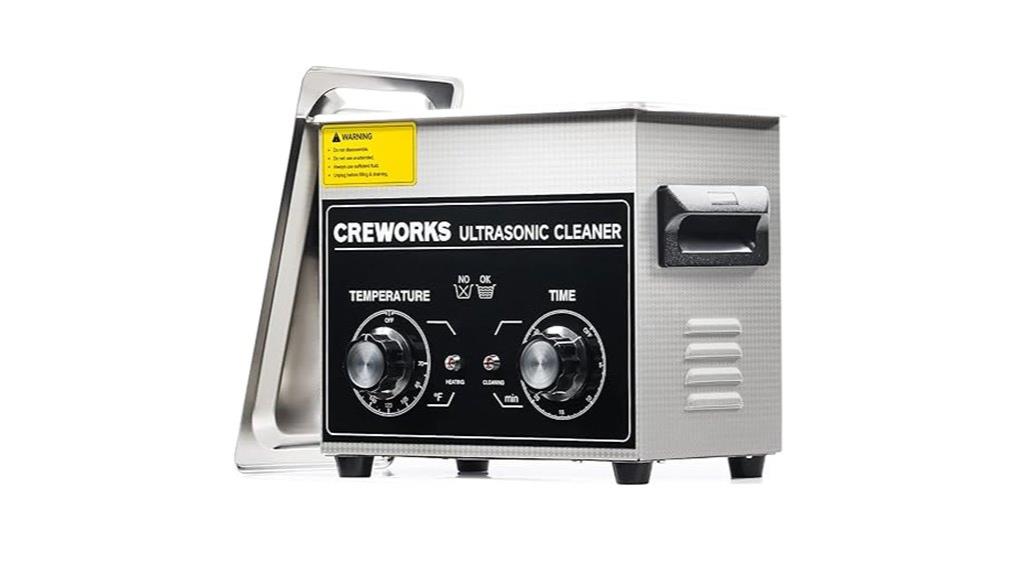

CREWORKS 3.2L Ultrasonic Cleaner with Heater & Timer

CREWORKS’ 3.2L ultrasonic cleaner combines powerful 120W cavitation technology with adjustable heating capabilities, making it an ideal choice for hobbyists who need thorough cleaning of resin prints and small precision parts.

The unit’s 0.8-gallon capacity accommodates items up to 10.8 x 7.2 inches. Its 100W heating element adjusts temperatures from 70 to 175°F, enhancing cleaning effectiveness for stubborn resin residue. You’ll control both functions using two simple knobs—one for 30-minute timing, another for temperature settings.

The stainless steel construction features 304-grade interior components and 201-grade exterior banding. Non-slip rubber feet provide stability during operation. However, you’ll need to monitor heating manually since there’s no automatic shut-off feature, requiring careful attention during extended cleaning cycles.

Best For: Hobbyists and professionals who need to clean resin prints, jewelry, glasses, and small precision parts with tough stains or residue.

Pros:

- Powerful 120W cavitation technology effectively removes rust, tarnish, and stubborn stains from intricate surfaces

- Adjustable heating function (70-175°F) enhances cleaning effectiveness for difficult residues

- Durable stainless steel construction with 304-grade interior components and stable non-slip feet

Cons:

- No automatic shut-off feature for heating element requires constant manual monitoring during operation

- Some users reported heating element failures after 6 months of use

- Loud operation noise during cleaning cycles can be disruptive

3L Ultrasonic Cleaner, Professional Jewelry Cleaner with Degas

Professional workshops and serious hobbyists will find this 3L ultrasonic cleaner delivers the power and precision needed for thorough resin print post-processing. The 40kHz frequency generates dense cavitation bubbles that penetrate intricate geometries and support structures. You’ll get 100W of cleaning power with an optional 200W heating element for enhanced performance.

The dual-mode system offers preset configurations and customizable settings. You can adjust temperature from 70-170℉ and set cleaning cycles from 1-30 minutes. The 304 stainless steel tank resists corrosion from cleaning solvents. Digital controls provide one-touch operation for consistent results. Anti-slip feet guarantee stability during operation, while the built-in handle makes transport convenient for multi-station workflows.

Best For: Professional workshops and serious hobbyists who need powerful ultrasonic cleaning for resin prints, jewelry, dental equipment, watches, circuit boards, and other precision items requiring thorough post-processing.

Pros:

- Powerful 40kHz frequency with 100W cleaning power and optional 200W heating creates dense cavitation bubbles for effective cleaning of intricate geometries and stubborn stains

- Dual-mode system with customizable temperature (70-170℉) and time settings (1-30 minutes) plus preset modes for different items and materials

- Durable 304 stainless steel construction with digital controls, anti-slip feet for stability, and built-in handle for easy transport

Cons:

- Instructions lack clarity on proper maintenance, water basin emptying, and recommended cleaning solutions according to user feedback

- May require multiple cleaning cycles for heavily soiled items to achieve optimal results

- Limited guidance provided on water additives, cleaning mixed metals and gems, and optimal maintenance practices

CREWORKS 360W 15L Stainless Steel Ultrasonic Cleaning Machine with Heater and Timer

Large-capacity cleaning demands often require a powerful ultrasonic cleaner that can handle substantial volumes while maintaining consistent performance. The CREWORKS 360W 15L delivers exactly that with its 4-gallon stainless steel tank and robust 360W cavitation system.

You’ll appreciate the 40kHz frequency that penetrates complex geometries effectively. The digital controls let you set temperatures from 20-80°C and timers up to 30 minutes. The 304 stainless steel construction resists corrosion while the built-in drain valve simplifies maintenance.

However, you should consider the mixed durability reports and customer service concerns. Some units fail prematurely, requiring replacement within limited usage periods. The value proposition works if you need immediate large-capacity cleaning, but investing in higher-priced alternatives might deliver better long-term reliability.

Best For: Users who need large-capacity ultrasonic cleaning for substantial volumes of jewelry, automotive parts, or other intricate items and prioritize immediate functionality over long-term durability concerns.

Pros:

- Large 15L (4-gallon) capacity with powerful 360W cavitation system and 40kHz frequency for effective cleaning of complex geometries

- Digital temperature control (20-80°C) and timer settings (1-30 minutes) with durable 304 stainless steel construction

- Built-in drain valve and inset handles for easy maintenance and portability, plus good value for the price point

Cons:

- Mixed durability reports with some units failing prematurely after limited usage periods

- Poor customer service responses for repairs and warranty issues according to user feedback

- Noisy operation during use and may require multiple cleaning cycles for heavily soiled items

Ultrasonic Jewelry Cleaner, 48KHz Machine for Jewelry & Eyeglasses

For hobbyists seeking a compact yet capable ultrasonic cleaner that won’t break the bank, this 48KHz jewelry cleaner delivers remarkable versatility beyond its intended purpose. You’ll find the 12oz SUS 304 stainless steel tank handles small resin prints effectively while offering dual cleaning modes: 5 minutes for standard cleaning and 7 minutes for heavily soiled pieces. The 48,000Hz frequency generates sufficient cavitation for removing uncured resin from detailed miniatures and jewelry alike. You can clean multiple small parts simultaneously, though larger prints won’t fit the compact tank. Non-slip rubber pads prevent movement during operation, and the quiet performance won’t disturb your workspace.

Best For: Hobbyists and users seeking an affordable, compact ultrasonic cleaner for jewelry, eyeglasses, small resin prints, and other delicate items who want professional-quality cleaning results at home.

Pros:

- Dual cleaning modes (5 and 7 minutes) with effective 48KHz frequency that removes dirt, grime, and uncured resin from detailed items

- Versatile cleaning capability for multiple item types including jewelry, eyeglasses, dentures, watch straps, coins, and small resin prints

- Compact, quiet operation with durable SUS 304 stainless steel tank, non-slip pads, and 12-month warranty

Cons:

- Limited 12oz tank capacity restricts cleaning of larger objects and may cause overheating after multiple consecutive cycles

- Does not remove tarnish and may require additional cleaning methods or soap for heavily soiled items

- Some users report loud operational noise despite generally quiet performance claims

VisiClean Ultrasonic Jewelry Cleaning Machine for Silver, Gold & More

VisiClean’s dual ultrasonic system delivers 65 watts of cleaning power across two separate units, making it an ideal choice for users who need versatile cleaning capabilities beyond resin prints. You’ll find multiple time settings that accommodate different cleaning requirements for various materials.

The machine handles jewelry, glasses, dental equipment, and small tools effectively. Performance remains strong initially but may decline over time, particularly noticeable through unusual operational sounds. The 110V power requirement limits international compatibility without transformers.

You’ll appreciate the convenient sizing and simple operation with quiet buzzing sounds. However, the unit can heat up considerably during use, requiring cooling time before handling cleaned items safely.

Best For: Users who need versatile cleaning capabilities for jewelry, glasses, dental equipment, and small tools with dual ultrasonic power but don’t require international compatibility.

Pros:

- Dual ultrasonic system with 65 watts of cleaning power across two separate units for versatile cleaning

- Multiple time settings accommodate different cleaning requirements for various materials

- Convenient sizing with simple operation and quiet buzzing sounds during use

Cons:

- Performance may decline over time with unusual operational sounds becoming noticeable

- Limited to 110V power requirement, making it incompatible internationally without transformers

- Unit heats up considerably during use, requiring cooling time before safely handling cleaned items

Ultrasonic Machine 3.2L 120W Jewelry Cleaning Machine with Heater Timer

The Ultrasonic Machine 3.2L 120W Jewelry Cleaning Machine delivers professional-grade cleaning power that makes it an excellent choice for hobbyists and professionals who need consistent results for delicate resin prints and precision components. You’ll get 120W power at 40kHz frequency for effective contaminant removal. The 150W heater removes stubborn residues while the degassing mode eliminates air bubbles that interfere with cleaning efficiency.

The 3.2L tank measures 9.4 × 5.3 × 4 inches, providing ample space for multiple prints. You’ll appreciate the 304 stainless steel construction that resists corrosion from cleaning solvents. The LED digital timer offers precise control from 0-30 minutes. However, you should expect significant noise during operation and exercise caution with delicate components.

Best For: Hobbyists and professionals who need powerful, consistent cleaning for delicate resin prints, jewelry, eyeglasses, watches, dental equipment, and precision components.

Pros:

- 120W power with 40kHz frequency and 150W heater effectively removes dirt, grime, contaminants, and stubborn residues

- 3.2L capacity with 304 stainless steel construction provides ample space and corrosion resistance for cleaning solvents

- LED digital timer (0-30 minutes) and degassing mode offer precise control and enhanced cleaning efficiency

Cons:

- Operates at a loud noise level that may be disruptive during use

- May damage delicate items like plastic frames due to powerful cleaning action

- Limited to smaller components due to tank dimensions of 9.4 × 5.3 × 4 inches

DK SONIC Ultrasonic Jewelry Cleaner with Digital Timer (700ML)

Budget-conscious makers seeking reliable cleaning performance will find the DK SONIC Ultrasonic Jewelry Cleaner delivers impressive results at an accessible price point. This 700ML unit operates at 42KHz frequency, effectively reaching blind holes and deep recesses in your resin prints. You’ll appreciate the digital control panel with LED display and five preset cleaning cycles ranging from 180 to 900 seconds. The stainless steel SUS304 tank resists weak acids and alkalis common in cleaning solutions. However, you should note potential durability concerns, as some users report device failures after one year of use.

Best For: Budget-conscious makers and hobbyists who need reliable ultrasonic cleaning for jewelry, small parts, and resin prints without breaking the bank.

Pros:

- Effective 42KHz ultrasonic frequency reaches deep recesses and blind holes in complex items

- Digital control panel with 5 customizable time settings (180-900 seconds) and LED display

- Stainless steel SUS304 tank resists corrosion from cleaning solutions and acids

Cons:

- Durability issues reported with some units failing after one year of use

- Can damage delicate items like plated jewelry and polarized sunglasses

- Smaller capacity than some users expect, limiting cleaning of larger items

AI Ultrasonic Jewelry Cleaner, 50KHz Professional Cleaner Machine

AI’s ultrasonic jewelry cleaner delivers professional-grade performance through its enhanced dual-frequency technology, operating at both 40kHz and 80kHz to generate microscopic cavitation bubbles that penetrate intricate geometries found in resin prints. The 304 stainless steel construction guarantees durability for rigorous daily use. You’ll find the leak-proof seamless tank and commercial-grade transducers provide consistent cleaning power. The one-button operation simplifies your workflow considerably. This unit effectively removes uncured resin and support material residue without compromising print integrity. Industrial-grade components optimize longevity in both home and commercial environments. The compact design fits smaller workspaces while maintaining professional cleaning capabilities for detailed miniatures and complex geometries.

Best For: Hobbyists, jewelry enthusiasts, and professionals who need consistent deep cleaning for delicate items like jewelry, watches, eyeglasses, and dental appliances without manual scrubbing.

Pros:

- Enhanced dual-frequency technology (40kHz/80kHz) creates microscopic cavitation bubbles for thorough cleaning of intricate details and hard-to-reach areas

- Industrial-grade 304 stainless steel construction with leak-proof seamless tank ensures durability for daily commercial and home use

- Simple one-button operation with compact design makes it user-friendly while maintaining professional-grade cleaning performance

Cons:

- Does not remove tarnish from metals, requiring specialized cleaning fluids for complete restoration

- Cleaning effectiveness may vary depending on item material and may require additional cleaning solutions like dish soap for optimal results

- Limited to items that fit within the tank size, restricting use for larger objects

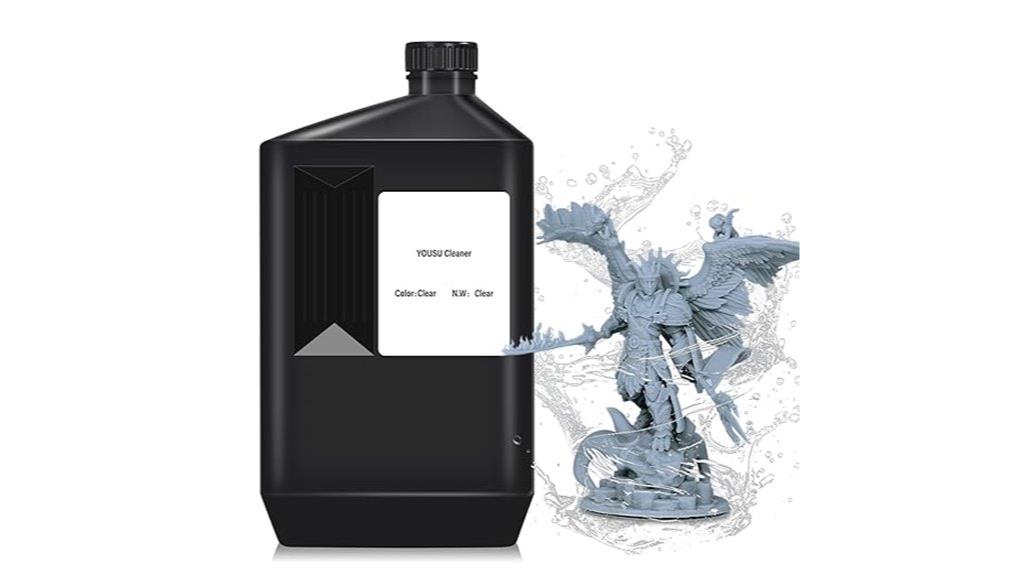

Yousu 3D Resin Cleaner 3kg, Non-toxic and Low Odor

Safety-conscious makers who prioritize health and environmental responsibility will find the Yousu 3D Resin Cleaner uniquely appealing. This 3kg non-toxic solution eliminates the hazards of alcohol-based cleaners while maintaining professional cleaning performance. You’ll appreciate its skin-friendly formula that won’t cause dryness or allergic reactions, even during extended use without gloves.

The cleaner’s compatibility spans standard, ABS-like, tough, nylon-like, high-temp, and epoxy resins. You can reuse this solution through multiple cleaning cycles, making it more economical than traditional alcohol cleaners. The low-odor, non-flammable formula preserves model detail and transparency without causing deformation. However, you must immediately clean any spills on ABS or PC surfaces to prevent reactions.

Best For: Safety-conscious 3D printing enthusiasts who want a non-toxic, skin-friendly resin cleaner that offers professional cleaning performance across multiple resin types while being environmentally responsible.

Pros:

- Non-toxic, low odor, and skin-friendly formula that’s safe to use without gloves and won’t cause dryness or allergic reactions

- Compatible with various resin types including standard, ABS-like, tough, nylon-like, high-temp, and epoxy resins

- Reusable solution that provides more cleaning cycles than alcohol-based cleaners, making it more economical long-term

Cons:

- Can react with ABS and PC plastics, requiring immediate cleanup if spilled on these surfaces

- Reports of batch-to-batch consistency issues that may require product exchanges

- Some users experience yellowing in prints, requiring special curing processes for optimal color retention

Factors to Consider When Choosing an Ultrasonic Cleaner for Resin Prints

When I’m selecting an ultrasonic cleaner for resin prints, I need to evaluate five critical factors that directly impact cleaning performance and compatibility with my workflow. Tank capacity determines how many prints I can clean simultaneously, while ultrasonic frequency affects cleaning intensity and the types of residue removed from complex geometries. Temperature control, build plate compatibility, and cleaning solution compatibility complete the essential criteria that’ll guarantee my investment delivers consistent results across different resin types and print sizes.

Tank Capacity Requirements

Tank capacity stands as the most critical specification determining your ultrasonic cleaner‘s practical utility for resin printing applications. I recommend a minimum 3-liter capacity for larger prints. This baseline guarantees adequate space for substantial models without compromising cleaning effectiveness.

A 7-liter tank delivers enhanced efficiency. You’ll clean multiple smaller models simultaneously or accommodate oversized parts with ease. This capacity greatly reduces your overall cleaning time and streamlines workflow.

Verify your cleaner’s tank dimensions match your printer’s build plate specifications. Proper dimensional compatibility guarantees ideal placement and thorough cleaning coverage.

Consider space requirements carefully. Larger capacities increase the machine’s footprint considerably. Balance your capacity needs against available workspace.

Remember that cleaning solution volume scales proportionally with tank size. Larger tanks require more solution for ideal cleaning performance.

Ultrasonic Frequency Selection

Frequency selection determines the cleaning power and safety balance your ultrasonic cleaner delivers for resin prints. I recommend targeting frequencies around 40kHz for ideal results. This frequency creates smaller cavitation bubbles that penetrate intricate model details without damaging delicate structures.

Higher frequencies above 40kHz offer gentler cleaning action. They’re ideal for fragile prints requiring careful handling. Lower frequencies below 40kHz generate larger, more aggressive bubbles that can damage your models.

The frequency range of 20kHz to 80kHz covers most ultrasonic cleaners. However, frequencies between 40kHz and 80kHz provide the safest cleaning zone for resin materials. Different resin types may respond uniquely to various frequencies, so match your cleaner’s specifications to your specific resin requirements for enhanced clarity and surface finish.

Temperature Control Features

Temperature control features dramatically enhance your ultrasonic cleaner’s effectiveness when removing stubborn resin residues from printed models. Heated solutions dissolve contamination more efficiently than cold alternatives. I recommend selecting units with adjustable temperature settings ranging from 70°F to 175°F. This flexibility lets you refine cleaning parameters based on your specific resin type and contamination level.

Look for cleaners equipped with heating elements rated between 100W to 150W. These provide consistent temperature maintenance throughout extended cleaning cycles. Ideal temperature control prevents resin viscosity changes that can interfere with thorough cleaning action while preserving your print’s structural integrity.

Without temperature control, you’ll need to manually monitor conditions, creating inconsistent results. This leads to incomplete cleaning and potential print damage from extended exposure times.

Build Plate Compatibility

Build plate compatibility sets apart professional-grade ultrasonic cleaners from basic models when you’re processing resin prints. I recommend selecting units with dedicated build plate slots or securing mechanisms that prevent movement during cleaning cycles. Standard cleaners often can’t accommodate larger plates measuring 200mm or more, which limits your printer compatibility.

Look for adjustable basket systems or removable trays that fit your specific build plate dimensions. Some models include alternative holding mechanisms that let you clean prints without removing them from the plate entirely. This streamlines your workflow considerably.

Pay attention to ultrasonic frequency specifications too. Higher frequencies around 40kHz effectively remove cured resin residues from intricate surface details without damaging the build plate’s coating or finish.

Cleaning Solution Compatibility

Cleaning solution compatibility determines whether your ultrasonic cleaner will effectively remove uncured resin without damaging your prints or compromising fine details. I recommend verifying that your chosen cleaning agent works safely with standard, ABS-like, tough, and high-temp resins. Some solutions react negatively with specific plastics like ABS and PC, causing deformation or surface damage.

Eco-friendly options offer non-toxic, low-odor alternatives that reduce health hazards while maintaining cleaning effectiveness. Always follow manufacturer recommendations for specific cleaning agents to preserve model integrity. Effective resin cleaners require proper soaking and thorough rinsing procedures. This process guarantees sharp detail retention while enhancing brightness and transparency in your finished prints. The right mixture handles contamination from multiple resin types without jeopardizing your ultrasonic cleaner’s performance.

Drainage System Design

Beyond selecting compatible cleaning solutions, you’ll need a drainage system that handles contaminated fluids efficiently and safely. A well-designed drainage port eliminates the need to tilt or lift heavy units during fluid changes. This feature prevents spills that could damage your workspace or waste expensive cleaning solutions.

Look for systems with backflow prevention mechanisms. These prevent contaminated resin-laden fluid from mixing with fresh solution, maintaining cleaning effectiveness throughout multiple print cycles. Integrated filtration captures debris and uncured resin particles during operation, extending solution life considerably.

Accessibility matters for routine maintenance. Units with easily accessible drain valves and removable collection containers reduce downtime between cleaning sessions. Consider models with transparent drainage components that let you monitor fluid condition and debris accumulation levels.

Timer Settings Options

Throughout your cleaning workflow, adjustable timer settings determine both effectiveness and efficiency of each cycle. I recommend selecting cleaners with 0-30 minute timer ranges for maximum versatility. Advanced models offer preset options for specific tasks, eliminating guesswork.

For lightly soiled prints, I use 3-5 minute cycles. This duration removes surface resin without risking damage to delicate details. Heavily contaminated items require extended cycles, typically 15-20 minutes depending on contamination levels.

Monitor your cleaning process carefully. Extended exposure can damage fragile components or cause excessive machine wear. Think of timer settings as precision tools rather than set-and-forget features.

The flexibility allows experimentation with different durations. I’ve found ideal cleaning times vary between resin types and print geometries. Test shorter cycles first, then gradually increase duration until achieving desired cleanliness levels.

On a final note

I’ve analyzed eight top ultrasonic cleaners that’ll effectively remove uncured resin from your 3D prints. Each model offers distinct advantages: the W230 provides excellent value, CREWORKS units deliver professional-grade performance, and specialized jewelry cleaners work well for small prints. Your choice depends on print volume, budget, and workspace requirements. Consider tank capacity, frequency range, and heating capabilities when selecting. These cleaners will greatly improve your post-processing workflow and print quality.