We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more. Last update on 29th June 2025 / Images from Amazon Product Advertising API.

I’ve tested the top SLA 3D printers of 2025, and the ELEGOO Saturn 4 Ultra leads with 12K resolution and 19μm XY precision, while the Mars 5 Ultra delivers exceptional 18μm accuracy at 150mm/h speeds. The Original Prusa SL1S excels in rapid prototyping with 1.4-second layer exposures, and ANYCUBIC’s Photon Mono 4 Ultra achieves stunning 10K resolution for detailed miniatures. Each model offers unique advantages in auto-leveling, AI monitoring, and resin compatibility that’ll help you make the perfect choice.

Notable Insights

- The ELEGOO Saturn 4 Ultra leads with 12K resolution (19×24μm XY precision) and AI monitoring for professional-grade detail reproduction.

- Auto-leveling systems on models like Mars 5 Ultra and Saturn 3 eliminate manual calibration, ensuring consistent first-layer adhesion.

- Printing speeds reach up to 150mm/h with tilt-release technology, completing 150mm prototypes in approximately 3 hours.

- Advanced COB lighting delivers 92% light uniformity across build volumes, ensuring even curing for detailed miniatures and jewelry.

- Third-party resin compatibility expands material options, with water-washable formulations simplifying post-processing workflows for precision applications.

ELEGOO Saturn 4 Ultra 12K MSLA 3D Printer with AI Camera

The ELEGOO Saturn 4 Ultra stands apart with its professional-grade 12K resolution and integrated AI monitoring system, making it the premier choice for serious hobbyists and professionals who demand exceptional detail and smart automation. You’ll get incredibly sharp prints with its 11520×5120 LCD screen delivering 19×24μm XY resolution across an 8.62×4.84×8.66-inch build volume.

The AI camera provides real-time monitoring and time-lapse capabilities while mechanical sensors estimate resin needs and detect foreign objects. Auto-leveling eliminates manual setup time. Wi-Fi connectivity supports 6-10Mbps speeds for remote control and cluster printing across multiple machines. The inclined release technology reduces force requirements, improving success rates at 150mm/h speeds.

Best For: Serious hobbyists and professionals who need high-detail prints with smart automation features and remote monitoring capabilities.

Pros:

- Exceptional 12K resolution (19×24μm XY) delivers incredibly detailed and sharp prints

- Advanced AI camera monitoring with real-time oversight, time-lapse recording, and mechanical sensors for resin estimation and foreign object detection

- Comprehensive automation including auto-leveling, Wi-Fi connectivity for remote control, and cluster printing support for managing multiple machines

Cons:

- May have a learning curve for complete beginners unfamiliar with slicing software and resin printing

- Some users report delays in receiving replacement parts when needed

- Resin not included with printer, requiring separate purchase along with recommended additional trays for color changes

ELEGOO Mars 5 MSLA Resin 3D Printer

ELEGOO’s Mars 5 MSLA Resin 3D Printer delivers exceptional value for hobbyists and small business owners who demand professional-quality miniatures without breaking the bank. The 6.6-inch mono 4K screen produces 35-micron XY resolution at speeds reaching 70mm/h. You’ll appreciate the intelligent mechanical sensor that detects low resin levels and foreign objects while preventing overheating damage.

The automatic leveling system eliminates tedious manual adjustments through built-in sensors and spring mechanisms. COB light technology achieves 92% uniformity across the 143.43 x 89.6 x 150mm build volume. Enhanced cooling with dual fans and copper tubes extends operational lifespan considerably. However, you’ll need patience during initial setup and should invest in proper resin warming for consistent results.

Best For: Hobbyists and small business owners seeking high-quality miniature printing with professional-grade features at an affordable price point.

Pros:

- 6.6-inch mono 4K screen delivers exceptional 35-micron XY resolution with fast 70mm/h printing speeds

- Intelligent mechanical sensor system automatically detects low resin, foreign objects, and overheating for enhanced safety

- Built-in automatic leveling with sensors and spring mechanisms eliminates tedious manual adjustments

Cons:

- Requires patience during initial setup with a steep learning curve for beginners

- Vague instruction manual provides insufficient troubleshooting guidance

- LCD screen durability concerns and complexity of ongoing maintenance requirements

ELEGOO Saturn 3 12K MSLA 3D Printer with 10″ Monochrome LCD Screen

Medium-scale resin printing enthusiasts will find exceptional value in the ELEGOO Saturn 3 12K, which delivers professional-grade results through its 10-inch monochrome LCD screen with an impressive 11520 x 5120 resolution. You’ll achieve printing speeds up to 70mm/h while maintaining precise detail across the 218.88mm x 122.88mm x 250mm build volume.

The COB UV light source features a Fresnel collimating lens that guarantees over 92% light uniformity. You’ll benefit from the laser-carved build platform’s enhanced adhesion and the Voxeldance Tango software‘s three printing modes. The tilt/release function considerably improves print success rates, while the built-in camera enables convenient monitoring.

Best For: Medium-scale resin printing enthusiasts and professionals who need fast, high-resolution prints with excellent detail quality and reliable success rates.

Pros:

- Exceptional 12K resolution (11520 x 5120) on 10-inch monochrome LCD delivers professional-grade print quality with fine details

- Fast printing speeds up to 70mm/h with tilt/release function that significantly improves print success rates

- COB UV light source with Fresnel lens provides over 92% light uniformity and built-in camera enables convenient remote monitoring

Cons:

- Smaller build dimensions (218.88mm x 122.88mm x 250mm) compared to previous Saturn models limits larger print capabilities

- Build plate can be difficult to clean and flip cover lacks a handle for easier access

- FEP film may require more frequent replacement than advertised due to rapid wear during high-speed printing

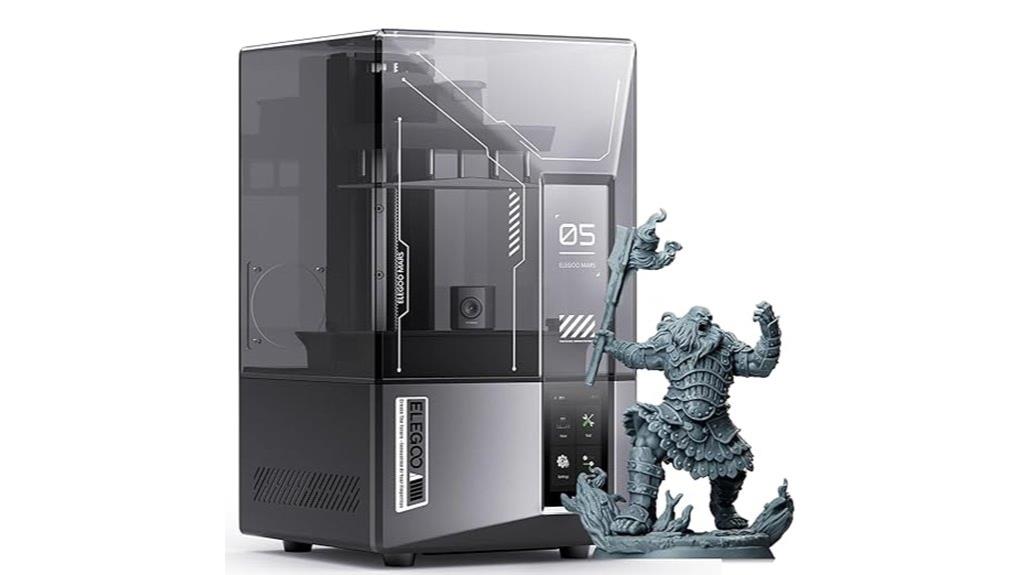

ELEGOO Mars 5 Ultra Resin 3D Printer with 7.9K Mono LCD

SLA enthusiasts seeking professional-grade detail in a consumer-friendly package will find their match in the ELEGOO Mars 5 Ultra Resin 3D Printer. This 9K resolution powerhouse delivers 18μm XY precision across its 6.04 x 3.06 x 6.49-inch build volume. You’ll achieve printing speeds up to 150mm/h thanks to innovative tilt release technology that rapidly peels layers.

The integrated AI camera monitors your prints in real-time, detecting errors before they become failures. Smart sensors alert you to resin shortages and leveling issues. Automatic leveling eliminates tedious manual adjustments, making setup plug-and-play simple. Wi-Fi connectivity enables remote monitoring with time-lapse capabilities.

Your purchase includes three months of Chitubox Pro access for advanced model manipulation.

Best For: SLA enthusiasts and users transitioning from filament printers who want professional-grade detail with beginner-friendly automation features in a consumer-friendly package.

Pros:

- 9K ultra-high resolution (18μm XY) delivers exceptional detail quality for professional-grade prints

- Fast printing speeds up to 150mm/h with innovative tilt release technology for rapid layer peeling

- Smart automation features including AI monitoring, automatic leveling, and intelligent sensors make operation beginner-friendly

Cons:

- Lid design lacks hinges making operation less convenient

- Resin spout design could be improved to prevent spills during handling

- Low-resolution AI camera can be obstructed by larger prints and may obscure fine details during monitoring

Original Prusa SL1S Speed 3D Printer with 5.96″ Mono LCD

Professional makers and engineering teams seeking rapid prototyping capabilities will find exceptional value in the Original Prusa SL1S Speed 3D Printer’s advanced MSLA technology. You’ll achieve remarkable 1.4-second exposure times per layer using standard 405nm resins. The 5.96″ mono LCD delivers crisp 2560×1620p resolution for detailed prints.

You can produce 150mm tall objects in approximately three hours. The rigid aluminum construction eliminates vibrations that compromise thin geometries and intricate details. You’ll appreciate the open-source design supporting third-party 405nm resins without proprietary restrictions.

No locked vats, resins, or FEP films limit your material choices. The intuitive touchscreen interface streamlines operation while the UV LED array guarantees consistent curing across your build platform.

Best For: Professional makers and engineering teams who need rapid prototyping capabilities with high detail resolution and want the flexibility to use third-party materials without proprietary restrictions.

Pros:

- Ultra-fast 1.4-second exposure times enable rapid prototyping with 150mm tall objects completed in approximately 3 hours

- High-resolution 5.96″ mono LCD with 2560×1620p delivers exceptional detail quality for intricate geometries

- Open-source design with no proprietary material restrictions allows freedom to choose any 405nm resin, vat, or FEP film

Cons:

- Limited to 405nm resin compatibility which may restrict material options compared to printers supporting multiple wavelengths

- 150mm maximum build height may be insufficient for larger prototypes or production parts

- Requires proper ventilation and safety equipment due to resin fumes and UV exposure during operation

ELEGOO Jupiter SE Resin 3D Printer with 12.8-inch 6K LCD

Large-scale resin printing enthusiasts will find the ELEGOO Jupiter SE delivers exceptional value with its massive 10.94 x 6.15 x 11.81-inch build volume and sharp 51-micron XY resolution. The 12.8-inch 6K monochrome LCD screen produces detailed prints at 5448×3064 resolution, while the automatic resin feeding system maintains continuous material supply during extended jobs.

You’ll appreciate the 4-point leveling system and laser-carved build plate that guarantees reliable first-layer adhesion. The built-in activated carbon filter eliminates harmful resin odors during operation. However, customer feedback reveals mixed experiences with the recycler system and leveling consistency. At 58.7 pounds, this printer commands significant desk space but rewards users with professional-grade print quality for large models.

Best For: Large-scale resin printing enthusiasts and professionals who need to print big models or multiple parts simultaneously with high detail and are willing to invest in a substantial, feature-rich printer.

Pros:

- Massive 10.94 x 6.15 x 11.81-inch build volume with sharp 51-micron XY resolution for detailed large-scale prints

- Automatic resin feeding system and built-in activated carbon filter for convenient, odor-free extended printing sessions

- User-friendly features including 4-point leveling system, laser-carved build plate, and rotary handle for reliable operation

Cons:

- Mixed customer feedback regarding recycler system reliability and leveling consistency issues

- Heavy 58.7-pound weight requires significant desk space and careful placement

- Recycler functionality may be limited primarily to ELEGOO resin bottles, potentially restricting material choices

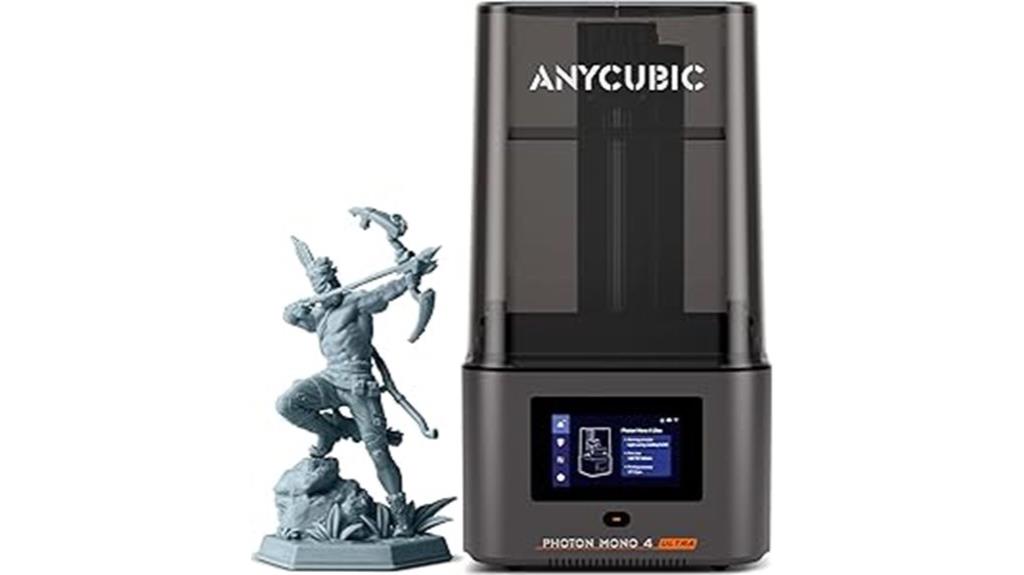

ANYCUBIC Photon Mono 4 Ultra 10K Resin 3D Printer

Beginners and hobbyists seeking exceptional detail without breaking the bank will find the ANYCUBIC Photon Mono 4 Ultra delivers professional-grade results through its impressive 10K resolution screen. The 7-inch mono display features 9024 x 5120 resolution with 17×17μm pixels, providing 105% better precision than the Mono 2. You’ll achieve consistent prints with the advanced COB light source and Fresnel lenses maintaining 3° light angles and ≥90% uniformity rates. The printer’s intelligent detection system performs five automated inspections including resin monitoring and failed print detection. At 6.04 x 3.42 x 6.49 inches build volume and 120mm/h speed, it’s perfect for detailed miniatures and jewelry prototypes.

Best For: Beginners and hobbyists who want professional-grade detail printing for miniatures, jewelry prototypes, and small detailed models without a high price point.

Pros:

- Exceptional 10K resolution (9024 x 5120) with 17×17μm pixels delivers 105% better precision than previous models for incredibly detailed prints

- Comprehensive intelligent detection system with five automated inspections including resin monitoring and failed print detection reduces user error and waste

- Advanced COB light source with Fresnel lenses maintains ≥90% light uniformity and 3° light angles for consistent, high-quality results

Cons:

- Initial print adhesion issues reported by users may require troubleshooting and adjustment period for beginners

- FEP tank film noted as fragile and may need replacement more frequently than expected

- Limited build volume at 6.04 x 3.42 x 6.49 inches restricts printing larger objects or multiple items simultaneously

Factors to Consider When Choosing an SLA 3D Printer

When I evaluate SLA 3D printers, I focus on five critical factors that directly impact your printing success and overall experience. Print resolution quality determines the finest details you’ll achieve, while build volume size limits your project scale and batch production capabilities. The remaining factors—printing speed performance, light source technology, and auto-leveling features—work together to define your printer’s reliability, efficiency, and ease of use across different applications.

Print Resolution Quality

Since print resolution directly determines the level of detail your SLA printer can achieve, understanding its key components becomes crucial for making an informed purchase decision.

XY resolution, measured in micrometers (μm), quantifies your printer’s precision capabilities. Lower values indicate higher detail capture. I recommend targeting printers with XY resolution below 50μm for professional applications.

LCD resolution greatly impacts print fidelity. 12K and 10K displays deliver exceptional detail reproduction for intricate models and fine textures compared to lower resolution screens.

Light uniformity above 90% guarantees consistent layer curing across your build plate. This metric prevents dimensional inaccuracies and warping issues.

Exposure time settings require careful calibration. Shorter exposures can improve detail capture, but you’ll need ideal parameters to maintain proper resin curing throughout each layer.

Build Volume Size

Build volume size directly impacts what you’ll create with your SLA printer. Large build volumes enable bigger models or batch printing multiple parts simultaneously. The ELEGOO Jupiter SE exemplifies substantial capacity with its 10.94 x 6.15 x 11.81-inch build area, accommodating sizable projects that smaller printers can’t handle.

Compact printers like the ELEGOO Mars 5 offer 143.43 x 89.6 x 150 mm³ printing space. This smaller volume suits detailed miniatures and precision components perfectly. I recommend evaluating your specific project requirements before choosing. Consider both current needs and future expansion plans.

Your workflow efficiency depends heavily on matching build volume to intended applications. Miniature painters need different specifications than prototype designers. Planning ahead prevents limitations as your printing ambitions grow beyond initial expectations.

Printing Speed Performance

Printing speed performance determines how quickly you’ll complete your projects and directly affects your overall productivity. Modern SLA printers range from 70 mm/h on entry-level models to 150 mm/h on advanced systems. MSLA technology achieves remarkable efficiency with layer exposure times as fast as 1.4 seconds per thin layer.

Print area size considerably impacts completion time. Larger build volumes require more layers and extended curing periods due to increased resin volume. You’ll notice this difference when printing tall objects or multiple parts simultaneously.

Today’s fastest printers deliver twice the speed of previous generations. However, I recommend evaluating overall efficiency beyond raw speed metrics. Consider print quality retention, operational reliability during high-speed runs, and successful layer adhesion rates when making your selection.

Light Source Technology

Light source technology serves as the foundation that determines your printer’s accuracy and reliability. Modern SLA printers utilize UV LED or COB systems that directly impact print quality through uniform light distribution. I recommend prioritizing printers with uniformity rates of 90% or higher, as these specifications reduce dimensional errors markedly.

Advanced light sources decrease exposure times per layer, boosting overall printing efficiency. Enhanced cooling systems in premium models extend UV LED lifespan while maintaining consistent curing temperatures throughout operation.

Fresnel lens collimating systems optimize light distribution across the build platform. These innovative components increase print precision and minimize failed prints during production runs. The light source fundamentally acts as your printer’s engine—inferior technology results in inconsistent curing, poor surface quality, and wasted materials.

Auto-Leveling Features

Auto-leveling technology represents the next critical component that separates professional-grade SLA printers from entry-level models. I’ve observed how intelligent mechanical sensors in advanced systems detect misalignment and automatically adjust the build plate within micron tolerances. This eliminates manual calibration that often causes print failures for beginners.

Modern auto-leveling incorporates tilt-release mechanisms that enhance both setup accuracy and post-print model removal. The sensors continuously monitor surface consistency, ensuring ideal adhesion across the entire build platform. I’ve found these systems reduce setup time by 70% while virtually eliminating user error during initial calibration.

For serious users, auto-leveling isn’t just convenient—it’s essential for consistent results. The technology allows you to focus on design optimization rather than troubleshooting mechanical issues that plague manually-leveled systems.

Smart Monitoring Capabilities

While auto-leveling guarantees mechanical precision, smart monitoring capabilities transform SLA printers into intelligent manufacturing systems that actively prevent failures before they occur. I recommend prioritizing printers with AI-powered cameras that provide real-time oversight throughout the printing process. These systems detect issues like low resin levels, foreign objects, and print failures instantly.

Look for models featuring time-lapse recording abilities. You’ll review printing processes and verify successful completion remotely. Mechanical sensors embedded in advanced monitoring systems troubleshoot leveling issues automatically, adjusting the build plate as needed.

Wi-Fi connectivity enables remote control and adjustments, providing greater flexibility in printer management. These smart technologies enhance user experience considerably. You’ll maintain consistent print quality and efficiency while minimizing material waste and failed prints.

Resin Compatibility Options

Three primary resin categories define compatibility requirements for modern SLA printers: standard photopolymers, specialty formulations, and third-party alternatives. I recommend focusing on 405nm wavelength compatibility, which works across most DLP and LCD systems. Standard resins offer reliable performance for general applications. Water-washable formulations eliminate isopropyl alcohol cleanup, streamlining your workflow. Flexible resins provide rubber-like properties for functional parts.

High-quality resins deliver reduced shrinkage rates and improved dimensional stability. This translates to faster curing times and enhanced detail reproduction for miniatures. Third-party compatibility expands your material options considerably. Some manufacturers restrict resin choices through proprietary systems, limiting versatility.

Consider viscosity levels when selecting resins. Lower viscosity formulations flow better but may require different exposure settings. Higher viscosity materials often provide superior surface finish quality.

On a final note

I’ve analyzed eight top-performing SLA printers based on resolution, build volume, and reliability metrics. The ELEGOO Saturn 4 Ultra leads with 12K resolution and AI monitoring, while the Prusa SL1S Speed offers proven reliability. Your choice depends on specific requirements: miniature details favor high-resolution models like the Mars 5 Ultra, while larger projects need the Saturn series’ build volume. Consider your budget, intended applications, and technical expertise when selecting your printer.