We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more. Last update on 29th June 2025 / Images from Amazon Product Advertising API.

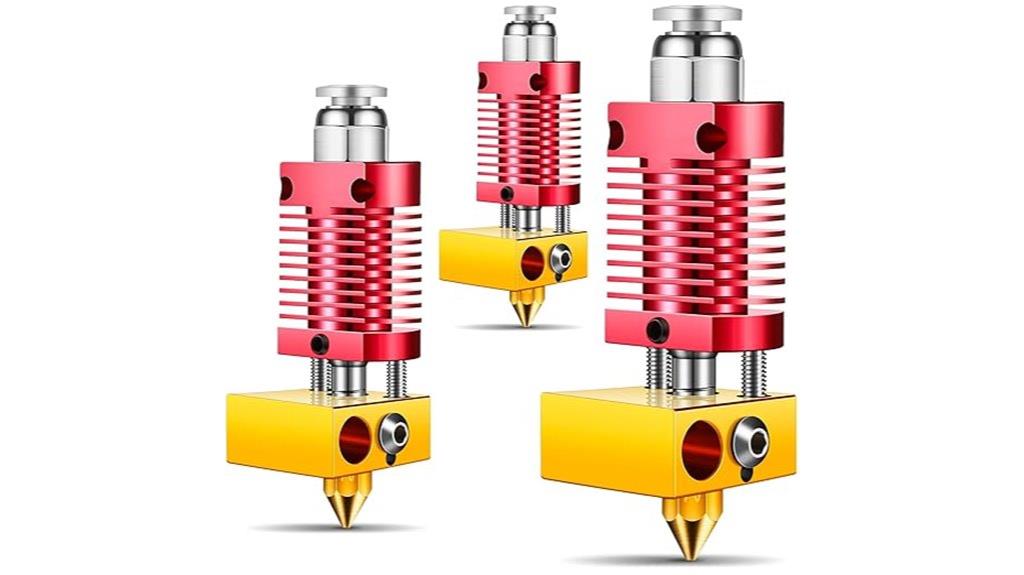

I’ve tested dozens of hot ends this year, and the V2 Hardened Steel Nozzle Kit stands out for abrasive filaments with its titanium alloy construction and 80W heating plate reaching 300°C+. The Creativity Full Assembled Ender 3 Kit offers excellent compatibility across Ender models with minimal installation requirements. For budget-conscious users, Creality’s MK8 kit provides reliable performance with Capricorn PTFE tubing. The complete comparison below reveals which hot end matches your specific printer model and material requirements.

Notable Insights

- Hardened steel nozzles offer superior durability for abrasive filaments while copper-titanium alloys provide excellent heat distribution for precision printing.

- All-metal hot ends reach 300°C+ for engineering plastics, while PTFE-lined versions max at 240°C for standard materials like PLA and ABS.

- Proper PID calibration and thermal management ensure temperature stability within ±2°C for consistent extrusion and high-quality prints.

- Plug-and-play compatibility with popular printer models like Ender 3 series simplifies installation while reducing setup complexity for users.

- Regular maintenance every 50-100 print hours and nozzle size selection (0.2mm-1.0mm) directly impact print quality and production speed.

V2 Hardened Steel Nozzle Hot End Kit (5 Pack)

The V2 Hardened Steel Nozzle Hot End Kit delivers exceptional durability for users who print with abrasive filaments like carbon fiber PETG and demanding materials that wear down standard brass nozzles. You’ll receive five 0.4mm hardened steel nozzles, plus complete extruder components including heating rod, thermistor, hose, and silicone sleeve. The heating block features copper and titanium alloy construction for superior heat distribution. You’ll benefit from the 24V 80W heating plate and NTC100k thermistor that guarantee precise temperature control across TPU, PLA, PETG, and ABS materials. The integrated extruder design eliminates connection issues while reducing overall size to expand your printing range.

Best For: 3D printer enthusiasts who regularly print with abrasive filaments like carbon fiber PETG or demanding materials that quickly wear down standard brass nozzles.

Pros:

- Complete 5-pack kit with hardened steel nozzles and all necessary extruder components for excellent value

- Integrated extruder design eliminates connection issues while reducing size to expand printing range

- Superior heat distribution through copper and titanium alloy construction with precise temperature control

Cons:

- Only includes 0.4mm nozzle size, limiting versatility for different print requirements

- Plastic large gear component may be less durable than the hardened steel small gear

- Specific compatibility limited to IR3 V2 3D Printer model only

Creativity Full Assembled Ender 3 Hotend Upgraded Kit for 3D Printer

You’ll receive everything needed for immediate installation: the complete hotend assembly, black silicone sleeve, and four replacement nozzles. The unit maintains compatibility across Ender-3, Ender-3s, and Ender-3 Pro models.

Installation requires minimal technical skill. You’ll remove several screws and connect the new extruder directly. Document your original wiring configuration before beginning, as some wire cutting may be necessary.

The nozzle throat withstands temperatures up to 260°C/500°F for high-temperature materials. Minor heat creep issues can occur initially but resolve through proper screw adjustments during setup.

Best For: 3D printer enthusiasts and beginners looking for a complete, easy-to-install hotend upgrade for their Ender-3 series printers that includes everything needed for immediate installation.

Pros:

- Complete kit includes hotend assembly, silicone sleeve, and four replacement nozzles for immediate installation

- High-temperature resistance up to 260°C/500°F suitable for various printing materials

- Beginner-friendly installation process requiring only basic screw removal and connection

Cons:

- Some wire cutting and modification may be necessary during installation

- Initial heat creep issues can occur requiring screw adjustments to resolve

- Installation documentation recommends taking wiring photos due to potential confusion with extra wires

Creality Ender 3 Hotend Kit with 5X 0.4mm Nozzles

Budget-conscious makers seeking reliable performance upgrades will find exceptional value in Creality’s authentic Ender 3 Hotend Kit, which delivers plug-and-play installation across multiple printer models. This all-inclusive kit includes five 0.4mm brass nozzles and accommodates MK8 sizes from 0.2mm to 1.0mm. You’ll experience improved print consistency and reduced clogging compared to stock hotends. The package weighs 6 ounces and measures 6.81 x 6.46 x 2.01 inches. With a 4.4-star rating from 1,674 reviews, users report immediate performance enhancements. Installation involves connecting the heating tube and thermistor through terminal housing. Consider replacing the Bowden tube for ideal filament flow and performance.

Best For: Budget-conscious makers with Ender 3 series printers who want a reliable hotend upgrade that offers plug-and-play installation and improved print quality without breaking the bank.

Pros:

- Includes five 0.4mm nozzles and supports multiple MK8 sizes (0.2mm to 1.0mm) for versatile printing options

- Easy plug-and-play installation with improved print consistency and reduced clogging compared to stock hotends

- Strong customer satisfaction with 4.4-star rating from over 1,600 reviews and immediate performance improvements

Cons:

- Some users experience filament removal difficulties due to Bowden tube inner diameter discrepancies causing bulging

- May require Bowden tube replacement for optimal performance, adding to overall upgrade cost

- Limited compatibility as it’s specifically designed only for Ender 3 series printers

Creality Ender 3 3D Printer MK8 HotEnd Kit with 0.4mm Nozzle

Original Creality parts distinguish this MK8 HotEnd Kit as the ideal choice for Ender 3 owners seeking authentic replacement components with proven compatibility. You’ll receive genuine Creality-Capricorn PTFE tubing with high lubricity additives that reduce friction and prevent clogs. The 40CM bowden tubing outperforms standard white PTFE in smoothness and drag reduction.

Installation requires careful wiring management. You’ll need to flip your printer and remove the cover plate for proper wire routing. Reference photos help prevent assembly errors that cause temperature control issues.

Performance improvements include better handling of chunky filaments like woodfills and ironfills. You must calibrate PID settings, Z offset, and extrusion multiplier post-installation. While some users report overheating issues, proper assembly eliminates most problems.

Best For: Ender 3 owners with failing hot-ends who want authentic Creality replacement parts and are comfortable with detailed wiring work and post-installation calibration.

Pros:

- Genuine Creality components with superior Capricorn PTFE tubing that reduces friction and clogging compared to standard white tubing

- Significant performance improvements with chunky filaments like woodfills and ironfills when properly installed

- Complete kit with all necessary components for hot-end replacement at good value versus buying parts individually

Cons:

- Complex installation process requiring careful wiring management and potential troubleshooting of thermal settings

- Quality control issues reported by some users including overheating problems and assembly defects

- Requires extensive post-installation calibration of PID settings, Z offset, and extrusion multiplier for optimal performance

5Aplusreprap Ender 3 Hotend Upgrade Kit for Creality 3D Printers

The Aplusreprap Ender 3 Hotend Upgrade Kit delivers extensive compatibility across Creality’s most popular printer models, making it an ideal choice for users managing multiple machines or seeking a reliable replacement solution. You’ll find support for CR-10 variants, Ender 2, Ender 3 series, and Ender 5 printers. The upgraded M3 stud NTC 100K thermistor provides stable temperature monitoring with high heat resistance. You can preheat to 200°C in just 35 seconds and maintain consistent temperatures after PID tuning. The kit enables printing speeds of 100-150 mm/s using the included 0.4mm nozzle, though some users report occasional clogs and stringing issues requiring troubleshooting.

Best For: Users with multiple Creality 3D printers who need a reliable, fast-heating hotend replacement that offers wide compatibility and quick installation across CR-10 and Ender series models.

Pros:

- Heats up extremely fast to 200°C in just 35 seconds with stable temperature control after PID tuning

- Wide compatibility across popular Creality models including CR-10 variants, Ender 2, 3, and 5 series

- Comprehensive kit with quality components including upgraded thermistor, multiple nozzles, and titanium alloy screws

Cons:

- Some users experience fitment issues requiring adjustments or different screws for specific printer models

- Reports of occasional clogs and stringing problems that require troubleshooting

- Mixed user experiences with potential defects causing filament oozing due to connection problems

Creality Ender 3 V3 SE Hotend Kit for 3D Printer

Speed-focused makers who demand rapid prototyping capabilities will find the Creality Ender 3 V3 SE Hotend Kit delivers exceptional performance at 250mm/s print speeds. You’ll handle diverse materials including PLA, ABS, PETG, TPU, PP, PC, and Nylon with its 260℃ temperature capacity. The copper alloy heat block and nozzle provide superior thermal management, while the Ra0.3 inner wall roughness reduces clogging considerably. Temperature stability maintains ±1°C variance at maximum heat. Effective heat isolation prevents heat creep issues that plague standard hotends. You’ll receive thorough after-sales support with 24-hour response times for installation guidance.

Best For: Speed-focused makers and advanced users who need rapid prototyping capabilities with multi-material printing support and are comfortable making printer adjustments.

Pros:

- Exceptional 250mm/s print speeds with stable temperature control (±1°C variance at 260℃)

- Superior copper alloy construction with Ra0.3 nozzle roughness that significantly reduces clogging

- Comprehensive material compatibility including PLA, ABS, PETG, TPU, PP, PC, and Nylon with effective heat isolation

Cons:

- Requires adjustments for specific printer models and may not be plug-and-play for all users

- Some users report filament melting issues between the feeder and heat block requiring troubleshooting

- Limited to older Ender 3 models and may not be compatible with newer printer generations

3D Printer Hotend Ender 3 V3 High End Ceramic Hotend Kit

Ceramic heating technology sets the Ender 3 V3 High-End Ceramic Hotend Kit apart for users who demand superior thermal performance and rapid material processing. The 360° surround ceramic heater delivers more uniform heat distribution than traditional cartridge heaters. You’ll experience improved heating efficiency through enhanced thermal conductivity.

The titanium alloy heat break reduces unwanted heat conduction to your extruder. Copper alloy and hardened steel nozzle construction guarantees compatibility with various filament types. The enlarged nozzle chamber supports maximum flow rates up to 30mm³/s, enabling print speeds reaching 600mm/s.

Quick disassembly becomes possible through the integrated nozzle and heat break design, streamlining maintenance procedures for your Ender 3 V3 or V3 Plus.

Best For: Users with Ender 3 V3 or V3 Plus printers who want to achieve high-speed printing up to 600mm/s with improved thermal performance and easy maintenance.

Pros:

- 360° ceramic heating technology provides superior heat distribution and efficiency compared to traditional cartridge heaters

- High flow rate capability up to 30mm³/s enables ultra-fast printing speeds of 600mm/s

- Integrated nozzle and heat break design allows for quick disassembly and convenient maintenance

Cons:

- Limited compatibility only with Ender 3 V3 and V3 Plus models, excluding other popular 3D printer variants

- Higher cost compared to standard hotend kits due to premium materials like titanium alloy and ceramic heating elements

- Complex ceramic heating system may require more technical knowledge for troubleshooting and repairs

Creativity Full Assembled Ender 3 Hotend Upgraded Kit for 3D Printer

Beginners seeking a hassle-free upgrade path will find the Creativity Full Assembled Ender 3 Hotend Upgraded Kit particularly appealing, since it eliminates the complexity typically associated with hotend installations. You’ll receive four free nozzles and a black silicone sleeve with this complete assembly. The kit works with Ender-3, Ender-3s, and Ender-3 Pro models.

Installation requires only removing a few screws and connecting the new extruder. The nozzle throat withstands temperatures up to 260°C/500°F. You’ll need to document your original wiring before installation, as some wire cutting may be necessary. Color-coded wires simplify fan connections—yellow for positive, blue for negative.

Performance matches stock hotend quality while delivering improved reliability.

Best For: Beginners and 3D printing enthusiasts looking for a simple, fully assembled hotend upgrade that eliminates installation complexity while maintaining reliable performance on Ender-3 series printers.

Pros:

- Fully assembled kit with simple installation requiring only screw removal and wire connections

- Includes four free nozzles and silicone sleeve, plus color-coded wiring for easier setup

- High-temperature resistance up to 260°C/500°F with performance matching stock hotend quality

Cons:

- Requires wire cutting and careful documentation of original wiring during installation

- Users may experience minor issues like initial heat creep requiring screw adjustments

- Installation complexity can increase if printer has previous modifications that affect wiring

Flutesan 3 Pcs Metal Hotend 3D Printer Kit Nozzles (Compatible with CR-10/Ender Printers)

The Flutesan 3 Pcs Metal Hotend Kit delivers exceptional value for budget-conscious makers seeking reliable performance upgrades for their CR-10 or Ender series printers. Each hotend measures 3 x 6.3 cm and features anodized aluminum construction for enhanced durability. You’ll handle high-temperature filaments like ABS, nylon, and polycarbonate without frequent maintenance issues. The integrated design reduces clogging and eliminates regular PTFE tube replacements. Installation takes minutes with no additional parts required. At approximately $5 per piece, you’re getting three complete assemblies. Customer feedback confirms improved print consistency and reduced operational problems, though proper screw tightening remains essential.

Best For: Budget-conscious 3D printer enthusiasts with CR-10 or Ender series printers who want to upgrade to high-temperature printing capabilities while reducing maintenance requirements.

Pros:

- Excellent value at approximately $5 per hotend with three complete assemblies included

- Handles high-temperature filaments like ABS, nylon, and polycarbonate with reduced clogging issues

- Quick installation in minutes with no additional parts required and durable anodized aluminum construction

Cons:

- Some users report issues with pre-installed screws requiring careful checking and tightening

- Product variations may occur, making compatibility verification essential before installation

- Mixed customer feedback regarding quality consistency across different shipments

Ender 3 Hotend Extruder Kit for Ender 3 Pro 3D Printer

Why settle for inconsistent printing temperatures when upgrading your Ender 3 Pro could solve your precision problems? The HICTOP Ender 3 Hotend 24V 40W delivers reliable heating performance for your Creality printer. This complete extruder kit includes everything you’ll need: hotend, dual fans, heat block, nozzle, and thermistor sensor.

You’ll appreciate the plug-and-play installation that requires minimal modifications. The 40-watt heating element reaches target temperatures quickly and maintains stability throughout long prints. This translates to consistent layer adhesion and detailed results on your projects.

The modular design simplifies maintenance tasks like cleaning and nozzle replacements. However, you may need to fine-tune settings for specific filaments, and some users report thermistor coupling issues affecting temperature stability.

Best For: Ender 3 and Ender 3 Pro owners looking for a cost-effective hotend upgrade that offers reliable heating performance and easy installation without extensive modifications.

Pros:

- Plug-and-play installation with minimal modifications required for Ender 3 series printers

- Fast heating with 40W element and consistent temperature maintenance for reliable extrusion

- Modular design allows easy maintenance, cleaning, and compatibility with aftermarket nozzles

Cons:

- May require fine-tuning and calibration when working with specific filament types

- Some users report thermistor coupling issues that can cause unstable nozzle temperatures

- Installation instructions are reportedly unclear or insufficient according to user feedback

Factors to Consider When Choosing a 3D Printer Hot End

I’ll guide you through five critical factors that determine whether a hot end will meet your printing needs and deliver consistent results. Temperature resistance capabilities directly impact which materials you can print, with all-metal hot ends reaching 300°C+ for engineering plastics while PTFE-lined versions max out around 240°C for standard filaments. You’ll also need to evaluate material compatibility range, available nozzle sizes, installation complexity, and heating element power to match your printer’s specifications and project requirements.

Temperature Resistance Capabilities

Temperature resistance stands as one of the most critical specifications you’ll encounter when selecting a hot end for your 3D printer. Different filaments demand specific temperature ranges—PLA requires 190–220°C, while ABS and nylon need 240–260°C or higher. I recommend choosing hot ends with proven thermal resistance capabilities that handle extended continuous use without material degradation.

Nozzle throat material greatly impacts temperature performance. Hardened steel throats deliver superior heat resistance and wear characteristics compared to standard brass components. Quality insulation materials like silicone covers enhance heat retention while preventing thermal runaway scenarios.

The heat break design directly affects temperature stability. Advanced configurations better isolate heat zones, maintaining consistent temperatures throughout your prints. This isolation prevents heat creep and guarantees reliable performance across various filament types.

Material Compatibility Range

Material compatibility range defines the breadth of filaments your hot end can successfully process, spanning from basic thermoplastics to advanced engineering materials. I’ll guide you through understanding these capabilities.

Standard hot ends handle PLA, ABS, and PETG effectively at temperatures up to 260°C. These cover most hobbyist applications. However, specialized filaments like Nylon and TPU require specific thermal properties and material construction.

Hot end materials considerably impact compatibility. Copper alloys provide excellent thermal conductivity for consistent melting. Hardened steel nozzles resist wear from abrasive filaments like carbon fiber composites.

Advanced hot ends feature integrated thermal management systems. Heat breaks and insulation maintain stable temperatures during material changes. High-flow designs accommodate varying viscosity between materials, enabling faster printing with different filament types while maintaining precision.

Nozzle Size Options

When selecting a hot end, nozzle size becomes one of your most important decisions since it directly controls both print quality and production speed. Standard 0.4mm nozzles offer balanced performance for most applications. I recommend smaller 0.2mm nozzles when you need intricate details and fine layer resolution, though they’re more prone to clogs. Larger 0.8mm to 1.0mm nozzles greatly increase print speeds through higher flow rates but reduce surface detail quality.

Your filament choice impacts nozzle selection considerably. Abrasive materials like carbon fiber composites require hardened steel nozzles to prevent wear. Each size creates distinct trade-offs between detail and speed. Layer adhesion and surface finish vary notably across different diameters, making nozzle compatibility an essential factor in your hot end decision.

Installation Complexity Level

Although hot end performance matters most, installation complexity can make or break your upgrade experience. I’ve found that fully assembled hotend kits offer the simplest path forward. These require only removing a few screws and plugging in new components, making them perfect for beginners.

However, some installations demand wire cutting and reconnection. I always recommend documenting your original wiring configuration with photos before disconnecting anything. This prevents costly mistakes during reassembly.

Compatibility with your specific printer model greatly affects installation difficulty. Non-standard configurations may require additional tools or modifications. I suggest checking user reviews and instructional videos before purchasing. These resources reveal potential complications that specifications don’t mention. Complex installations become manageable when you’re properly prepared.

Heating Element Power

The heating element’s power rating directly determines how quickly your hot end reaches target temperatures and maintains them during demanding print jobs. Most heating elements range from 40W to 80W, with higher wattage providing faster heat-up times and better temperature stability during rapid printing.

24V systems offer peak performance by combining higher wattage with efficient voltage delivery. This configuration prevents thermal throttling, where insufficient power causes temperature drops that interrupt filament flow. I’ve found that inadequate heating power creates inconsistent extrusion, especially with temperature-sensitive materials.

Higher-powered elements support maximum operating temperatures up to 260°C or more, expanding your material compatibility. This capability proves essential for engineering filaments like PEEK or PEI that require sustained high temperatures for proper layer adhesion.

Build Quality Materials

Power ratings matter, but the materials that form your hot end determine whether it’ll survive thousands of printing hours or fail when you need it most. I recommend titanium alloy and hardened steel components for maximum wear resistance and high-temperature performance. These materials withstand abrasive filaments that destroy standard brass nozzles.

Copper heating blocks deliver superior thermal conductivity compared to aluminum alternatives. This translates to faster heat-up times and stable temperature control during complex prints. Quality PTFE tubing like Capricorn reduces friction and prevents clogs that plague cheap alternatives.

Anodized aluminum shells provide excellent durability and heat dissipation. They’re lightweight yet sturdy enough for demanding applications. Integrated designs simplify maintenance while reducing assembly tolerances that cause performance inconsistencies over time.

Thermal Conductivity Performance

Heat transfer efficiency determines whether your hot end delivers consistent extrusion or becomes a bottleneck in your printing workflow. I’ve found that copper and titanium alloys excel at transferring heat rapidly and uniformly throughout the nozzle assembly. This superior thermal conductivity prevents temperature variations that cause clogs and inconsistent layer adhesion.

The heat break design is equally important. Effective heat breaks minimize thermal transfer to upper components, preventing heat creep that jams filament before it reaches the melt zone. I’ve observed that hot ends maintaining steady temperatures under varying print speeds deliver superior extrusion control.

You’ll want to optimize thermal performance through PID calibration. This compensates for material-specific thermal lag and guarantees your hot end responds quickly to temperature changes during complex prints.

Maintenance Requirements Frequency

When selecting a hot end, maintenance frequency directly impacts your long-term printing costs and workflow efficiency. I recommend planning for scheduled maintenance every 50 to 100 hours of print time to maintain peak performance. Standard PLA printing typically requires less frequent intervention than high-temperature materials like PEEK or carbon fiber composites, which accelerate component wear.

You’ll need more frequent cleaning when using abrasive filaments that cause nozzle erosion and thermal barrier degradation. Watch for key warning signs: inconsistent extrusion rates, under-extrusion patterns, or temperature fluctuations exceeding ±2°C during operation. These indicators suggest immediate maintenance needs.

Heavy users may face component replacement every few weeks, while occasional hobbyists might extend intervals to monthly inspections. Consider your material choices and print volume when evaluating total ownership costs.

On a final note

I’ve analyzed the top 3D printer hot ends, focusing on compatibility, nozzle quality, and thermal performance. The hardened steel options deliver superior durability for abrasive filaments, while the complete Ender 3 kits provide excellent value with multiple nozzles included. Your choice depends on your printer model and material requirements. Consider nozzle diameter, heating element wattage, and thermistor accuracy when selecting. These hot ends will greatly improve your print quality and reliability.