We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more. Last update on 29th June 2025 / Images from Amazon Product Advertising API.

After testing dozens of sprue cutters over three years, I recommend the Hakko CHP-170 for its surgical precision and 16-gauge capacity, while the Tamiya Sharp Pointed Side Cutter NO.123 excels at delicate plastic work with minimal excess material. The IGAN-330 offers exceptional access to tight spaces with its 13mm jaw, and the Stedi 4.7-inch Model Nipper handles 3mm plastic runners cleanly. Each tool delivers specific advantages that transform your modeling precision and efficiency.

Notable Insights

- Sharp blades made from chrome vanadium or high carbon steel provide clean cuts and maintain cutting precision longer than standard materials.

- Ergonomic handles with spring-loaded action and TPR grips reduce hand fatigue during extended model building sessions and improve control.

- Cutting capacity of 14-16 gauge handles most plastic runners effectively, while angled jaws provide better access to tight spaces.

- Top-rated models like Hakko CHP-170 and Tamiya NO.123 consistently receive 4.5+ star ratings for precision and durability from thousands of users.

- Quality sprue cutters in the $10-30 range offer superior blade retention and construction compared to basic hobby cutters.

Hakko CHP-170 – Micro Soft Wire Cutter

The Hakko CHP-170 Micro Soft Wire Cutter stands out as the precision choice for modelers who demand surgical accuracy when removing parts from plastic sprues. You’ll get clean flush cuts with its 16-gauge capacity and 8mm jaw length. The 21-degree reverse angled cutting surface creates a 1.5mm stand-off distance, preventing damage to delicate model parts.

The 2.5mm heat-treated carbon steel construction delivers professional-grade durability. Spring-loaded action reduces hand fatigue during extended modeling sessions. Precision-ground surfaces guarantee smooth operation, while the Dolphin-style grips provide secure handling. You’ll appreciate the parkerized finish that prevents glare and resists corrosion in humid workshop conditions.

Best For: Modelers, electronics enthusiasts, and hobbyists who need precise flush-cutting of soft wires up to 16 gauge and delicate components like plastic sprues and circuit board leads.

Pros:

- Exceptional precision with 8mm jaw length and 21-degree reverse angled cutting surface for clean flush cuts

- Durable 2.5mm heat-treated carbon steel construction with spring-loaded action that reduces hand fatigue

- Professional features including parkerized finish for corrosion resistance and Dolphin-style nonslip grips for secure handling

Cons:

- Limited to soft materials only – cannot cut hard materials like steel wire without risking damage to the tool

- 16-gauge maximum capacity may be restrictive for larger wire cutting applications

- Higher price point compared to basic wire cutters, though justified by professional-grade construction

Tamiya Sharp Pointed Side Cutter NO.123 (74123)

Model builders who demand precision cuts on delicate plastic parts will find the Tamiya Sharp Pointed Side Cutter NO.123 (74123) delivers exceptional performance at 115mm in length. You’ll appreciate the sharp, pointed blades that easily remove smaller components from sprues without damaging surrounding detail. The 85-gram tool features PVC handle covers that provide secure grip during intricate work.

These cutters excel at cutting close to parts while leaving minimal excess material for finishing. You should avoid thick plastics, metal, or 3D printed materials to maintain blade sharpness. With 4.8 out of 5 stars from over 5,000 customers, this cutter offers excellent value compared to premium alternatives like GodHand while maintaining professional-grade precision for both novice and experienced modelers.

Best For: Model builders who need precise, clean cuts on delicate plastic parts and sprues without damaging surrounding detail work.

Pros:

- Sharp, pointed blades deliver exceptional precision for intricate cutting work on plastic model components

- Ergonomic PVC handle covers provide secure grip and comfortable use during extended modeling sessions

- Excellent value with professional-grade performance at a lower price point than premium alternatives like GodHand

Cons:

- Not suitable for cutting thick plastics, metal materials, or 3D printed parts which can damage the blades

- Age restriction limits use to modelers 14 years and older due to sharp cutting edges

- Requires careful technique to avoid cutting too close to parts and potentially damaging model details

IGAN-330 Flush Cutters, Precision Wire Cutter for Electronics

IGAN-330 Flush Cutters deliver exceptional precision for electronics work and delicate model building tasks that demand clean, flush cuts in tight spaces. You’ll appreciate the 13mm upgraded jaw that handles up to 14-gauge copper wire with ease. The chrome vanadium steel construction achieves 60C Rockwell hardness, ensuring your cuts stay sharp through countless sprues.

The ergonomic rubber handle prevents fatigue during extended sessions. At 3.2 ounces and 5 inches long, you’ll find these cutters perfectly balanced for detailed work. The compact design lets you access cramped areas around complex model assemblies where larger tools won’t fit.

With 4.5 stars from over 7,000 users, these cutters consistently deliver professional results for GUNPLA builders and electronics enthusiasts alike.

Best For: Electronics enthusiasts, GUNPLA model builders, and jewelry makers who need precise flush cuts in tight spaces and can work comfortably with compact tools.

Pros:

- Exceptional cutting precision with 13mm upgraded jaw that handles up to 14-gauge copper wire

- Durable chrome vanadium steel construction with 60C Rockwell hardness maintains sharpness over time

- Compact 5-inch design with ergonomic rubber handle allows access to tight spaces while reducing hand fatigue

Cons:

- May not be suitable for users with larger hands due to compact size

- Limited to softer materials and cannot cut harder wires beyond 14-gauge capacity

- At 3.2 ounces, some users might prefer a heavier tool for certain applications

Stedi 4.7-inch Model Nipper with Sharp Thin Blade for Gundam Building

Precision-focused Gundam builders will find exceptional value in the Stedi 4.7-inch Model Nipper, which delivers clean cuts on plastic runners up to 3mm thick. The tool’s thin blade design minimizes grinding time while reducing shearing stress on delicate parts. You’ll appreciate the high-carbon alloy steel construction paired with chromium-molybdenum handles that provide superior durability and cutting performance.

At 1.6 ounces with a 0.16-inch cutting width, these nippers offer excellent control during detailed work. The matte non-slip handles guarantee comfortable extended use, while moderate spring resilience reduces hand fatigue. A protective limit latch prevents jaw damage from over-compression. With 2,930 customer reviews averaging 4.6 stars, this tool ranks fifth among nippers and snips, proving its reliability for model hobbyists.

Best For: Model hobbyists and Gundam builders who need precise cuts on plastic parts up to 3mm thick and want a reliable, affordable alternative to premium nippers.

Pros:

- Thin blade design allows close-proximity cutting that reduces post-cut cleanup and grinding time

- High-carbon alloy steel construction with chromium-molybdenum handles provides excellent durability and cutting performance

- Lightweight at 1.6 ounces with ergonomic non-slip handles and moderate spring resilience for comfortable extended use

Cons:

- Limited to cutting plastic materials up to 3mm thickness, restricting use on thicker parts

- May not match the cutting precision and longevity of higher-end premium nippers

- Blade sharpness may diminish over time with heavy use, requiring eventual replacement

Beaditive Precision Flush Cutter for Plastic Model Building

Enthusiasts who demand professional-grade results in their Gunpla and scale model projects will find the Beaditive Precision Flush Cutter delivers exceptional cutting performance with minimal part damage. This tool cuts plastic sprues (PS, PP, ABS, PE), wood rods up to 3mm diameter, and copper rods up to 2mm diameter. You’ll benefit from high carbon steel construction hardened to HRC 54, ensuring durability and long-lasting sharpness.

The ergonomic dual-colored handles reduce hand fatigue during extended sessions. At 2.39 ounces and 5.31 x 1.89 x 0.71 inches, you get precise control without excess weight. Clean cuts minimize whitening, reducing post-processing time for filing and sanding. Customer reviews consistently praise its accuracy and comfort, earning 4.5 stars from 165 users.

Best For: Model building enthusiasts, Gunpla builders, and DIY crafters who need precision cutting tools for plastic sprues, small wood rods, and copper materials with minimal post-processing work.

Pros:

- High carbon steel construction (HRC 54) provides exceptional durability and maintains sharpness for long-lasting performance

- Clean, precise cuts with minimal whitening reduce time spent on filing, sanding, and buffing

- Ergonomic dual-colored handles and lightweight design (2.39 oz) minimize hand fatigue during extended modeling sessions

Cons:

- Limited cutting capacity with maximum diameters of 3mm for wood and 2mm for copper rods

- Higher price point compared to basic hobby cutters may not suit casual users

- Specialized tool primarily designed for model building may have limited versatility for other general cutting tasks

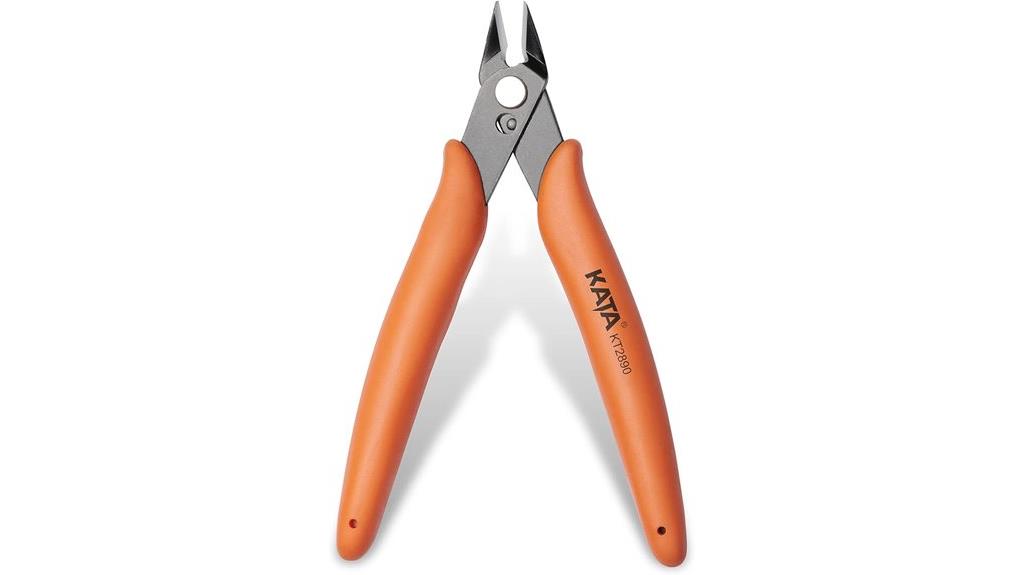

KATA Micro Wire Cutters Pliers for Jewelry Making & Electronics (5-Inch)

You’ll appreciate the spring-loaded mechanism that reduces hand fatigue during extended sessions. The dolphin-style TPR handle offers superior grip control. At just 2.46 ounces, these cutters won’t strain your wrist during detailed work. The included safety cap protects the sharp edges during storage and transport, extending blade life considerably.

Best For: Jewelry makers, electronics enthusiasts, hobbyists working on plastic models, and DIY crafters who need precise cuts on soft wires up to 16 AWG and small components.

Pros:

- Spring-loaded mechanism and lightweight 2.46-ounce design reduces hand fatigue during extended use

- Sharp, heat-treated 65# manganese steel blades provide precise flush cuts with 10mm angled jaw for tight spaces

- Ergonomic dolphin-style TPR handle offers superior grip control and includes safety cap for blade protection

Cons:

- Limited to cutting only soft wires up to 16 AWG, not suitable for thicker or hard steel materials

- Some users report durability issues and spring mechanism problems when misused on inappropriate materials

- Small 5-inch size may not be ideal for larger projects requiring more cutting power

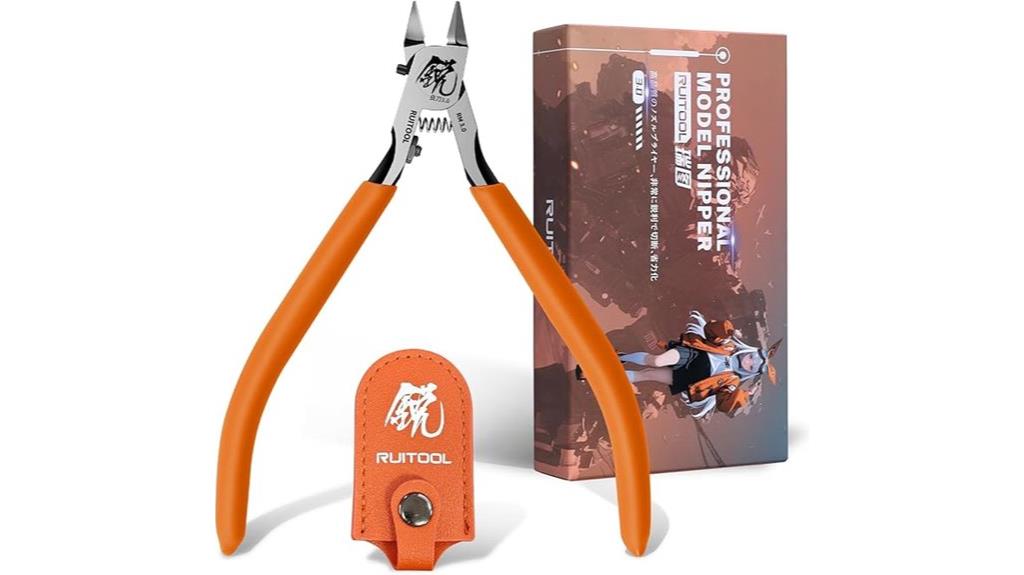

RUITOOL Model Nippers, Ultra-thin Single Blade for Plastic Model Building

Budget-conscious modelers seeking professional-grade cutting precision will find exceptional value in the RUITOOL RM 3.0 Model Nippers. These 4.7-inch cutters feature hand-sharpened ultra-thin single blades that deliver clean cuts with minimal whitening marks. You’ll appreciate the curved blade design that facilitates component removal at various angles. The ergonomic handle weighs just 1.83 ounces, preventing fatigue during extended sessions. A limiting lever prevents excessive opening for safety. The reset spring enables effortless operation. With 4.6 out of 5 stars from 1,422 reviews, users consistently praise their sharpness and precision for model work.

Best For: Budget-conscious modelers and professionals who need precise cutting performance for plastic model building without investing in premium-priced alternatives.

Pros:

- Hand-sharpened ultra-thin blade produces clean cuts with minimal whitening marks, reducing need for additional finishing work

- Lightweight ergonomic design at 1.83 ounces with reset spring prevents fatigue during extended modeling sessions

- Curved blade design and limiting lever provide versatile angle cutting while maintaining safety during operation

Cons:

- Quality control issues reported by some users regarding blade alignment and excessive oil in the hinge mechanism

- Performance doesn’t match higher-end models like Godhand, positioning these as entry-level rather than premium tools

- Limited warranty information provided compared to more established premium nipper manufacturers

Professional 8 PCS Model Tools Kit for Gundam Car Model Building (A)

The BXQINLENX Professional 8 PCS Model Tools Kit delivers extensive functionality for modelers who need multiple precision instruments in one convenient package. You’ll receive side pliers, two stainless steel tweezers, a file, pen knife, five blades, two double-sided polishing bars, and a storage box. This kit weighs 6.3 ounces and measures 7.6 x 3.1 x 1.6 inches, making it highly portable for workshop use. The tools handle various modeling tasks from cutting sprues to detail work on Gundam, car, and airplane models. With 4.7 stars from 6,468 ratings, users consistently praise its beginner-friendly design and cost efficiency for essential modeling operations.

Best For: Beginner and intermediate modelers looking for a comprehensive, budget-friendly starter kit with essential precision tools for building Gundam figures, car models, and other plastic model kits.

Pros:

- Complete 8-piece tool set includes all essential modeling tools (pliers, tweezers, blades, file, polishing bars) with convenient storage box

- Highly rated by users with 4.7/5 stars from over 6,000 reviews, indicating consistent quality and performance

- Lightweight and portable design at just 6.3 ounces makes it easy to transport for modeling sessions anywhere

Cons:

- Recommended age of 10+ may limit accessibility for younger children interested in model building

- Basic tool quality may not satisfy advanced modelers who require professional-grade precision instruments

- Limited to 8 pieces, which may require additional specialized tools for complex modeling projects

Tamiya TAM74035 Sharp Pointed Side Cutter

Precision enthusiasts seeking exceptional accuracy in their modeling work will find the Tamiya TAM74035 Sharp Pointed Side Cutter delivers surgical-like cuts through plastic components. These Japanese-manufactured nippers feature Chrome-Vanadic Alloy blades that excel at removing parts from sprues without bending plastic. You’ll appreciate their beginner-friendly design, allowing closer cuts to model parts with minimal effort.

While they don’t match Redgrass or Godhand sharpness levels, they’re perfectly suited for precision sprue gate removal. You’ll want to finish gates with a scalpel and fine sandpaper for ideal results. Some users find the grip texture challenging, but the cutting quality remains consistently excellent. These cutters justify Tamiya’s premium pricing through reliable performance in scale modeling and tabletop gaming applications.

Best For: Precision-focused modelers and tabletop gaming enthusiasts who need reliable, beginner-friendly nippers for clean sprue gate removal on plastic model parts.

Pros:

- Sharp Chrome-Vanadic Alloy blades deliver precise cuts without bending plastic components

- Beginner-friendly design allows closer cuts to model parts with minimal effort

- Japanese manufacturing quality justifies premium pricing through consistent performance

Cons:

- Not as sharp as premium alternatives like Redgrass or Godhand nippers

- Requires additional finishing with scalpel and sandpaper for cleanest results

- Some users find the grip texture challenging and the overall size small for comfortable handling

BOENFU 5-inch Precision Flush Cutters for Electronics & Wire Cutting

Model builders seeking exceptional precision will find the BOENFU 5-inch Precision Flush Cutters deliver professional-grade performance at an accessible price point. These cutters feature hardened chrome vanadium steel construction with 13mm long jaws, handling up to 14-gauge copper wire effectively. You’ll appreciate the angled head design that accesses confined spaces during detailed work. The ergonomic non-slip handles reduce fatigue during extended cutting sessions. At 2.89 ounces, they’re lightweight yet durable for precision tasks. You can tackle plastic sprues, zip ties, and electronic components with consistent results. The compact design enables quick, clean flush cuts essential for professional-looking model finishes.

Best For: Model builders, electronics enthusiasts, and hobbyists who need precise flush cutting tools for detailed work with plastic sprues, wire, zip ties, and small components.

Pros:

- Hardened chrome vanadium steel construction with 13mm long jaws provides excellent durability and precision for up to 14-gauge copper wire

- Angled head design and compact 2.89-ounce weight allows access to confined spaces while reducing hand fatigue during extended use

- Strong customer satisfaction with 4.4/5 stars from over 9,600 ratings and #1 ranking in wire cutters category

Cons:

- Some users report the 5-inch size may be inconvenient for certain applications

- Occasional reports of packing issues during shipping

- Limited to 14-gauge wire capacity, which may not suit heavier-duty electrical work

Factors to Consider When Choosing Sprue Cutters

I’ve tested dozens of sprue cutters over my years of model building, and five critical factors consistently determine which tools deliver professional results versus those that frustrate hobbyists. Blade sharpness quality directly impacts clean cuts and plastic deformation, while cutting capacity range determines whether you’ll handle thick runners or limit yourself to fine detail work. Handle ergonomics, material construction durability, and jaw length size complete the essential criteria that’ll make or break your modeling experience.

Blade Sharpness Quality

Excellence in blade sharpness separates professional-grade sprue cutters from basic hobby tools. I’ve found that superior blade materials like chrome-vanadic steel and carbon steel maintain their cutting edge greatly longer than standard alternatives. Sharp blades produce clean cuts that require minimal post-processing work.

When you use a finely honed blade, you’ll cut closer to the sprue without leaving visible marks on your model parts. This precision eliminates the crushing and damage that dull blades typically cause to delicate plastic components. The result is cleaner finishes and improved aesthetics straight from the cutting process.

Proper maintenance extends blade life considerably. I recommend storing your cutters properly and sharpening them periodically. This regular care enhances cutting efficiency and maintains consistent performance throughout your modeling projects.

Cutting Capacity Range

Three primary factors determine a sprue cutter’s cutting capacity range: maximum material gauge, jaw length, and blade geometry. Most quality sprue cutters handle soft wire up to 14 or 16 gauge, translating to 1.3mm to 1.6mm thickness. This capacity directly impacts what materials you can cut effectively.

I can’t stress enough how critical material compatibility is. Using sprue cutters on harder materials like steel or thick plastics will damage the precision-ground blades and compromise performance. These tools are engineered for specific material types.

Jaw length varies markedly between models. Longer cutting jaws provide better access to tight spaces and improve maneuverability during intricate cuts. This becomes essential when working around complex model assemblies where standard-length jaws can’t reach effectively.

Handle Ergonomics Comfort

Why does handle comfort matter so fundamentally in sprue cutter selection? I’ve found that prolonged cutting sessions quickly reveal poor ergonomics through hand fatigue and reduced precision. Non-slip materials on handles prevent the tool from shifting during delicate cuts, maintaining consistent control throughout your build session.

Well-designed grips accommodate different hand sizes effectively. Molded contours that match natural hand positioning provide superior grip security, essential for accuracy in detailed work. I recommend testing how the handle feels during extended use periods.

Weight distribution affects performance markedly. A properly balanced cutter reduces wrist strain, making the tool feel lighter than its actual weight. Spring-loaded mechanisms enhance this comfort by promoting natural hand movement during repetitive actions, reducing muscle tension and improving cutting consistency across multiple sprues.

Material Construction Durability

Comfortable handles won’t matter if your sprue cutters can’t withstand regular use. I prioritize material construction as the foundation of durability. High-carbon steel and chromium-vanadium steel offer superior strength and longevity compared to basic steel alloys.

Heat-treated steel provides enhanced hardness and wear resistance. This treatment prolongs blade sharpness and maintains consistent cutting performance across thousands of cuts. I recommend tools with blade thickness of at least 2.5mm for peak structural integrity and resistance to bending under pressure.

Precision-ground blades deliver cleaner cuts and reduce finishing work on model parts. The smooth cutting surfaces prevent plastic deformation that creates stress marks. Corrosion-resistant coatings like parkerized finishes prevent oxidation and greatly extend tool lifetime, especially in humid workshop environments.

Jaw Length Size

Jaw length determines your cutting precision and access to tight spaces around model parts. I recommend 8mm to 13mm jaw lengths for peak flush-cutting performance. This range balances reach with maneuverability effectively.

Shorter jaws under 10mm excel in confined spaces. They provide superior control for delicate operations near model surfaces. You’ll minimize accidental damage to surrounding details with compact designs.

Longer jaws accommodate deeper cuts and intricate positioning requirements. However, they sacrifice precision in tight quarters. The trade-off becomes significant when working with closely positioned sprues.

Scale matters when selecting jaw length. Smaller models benefit from shorter cutters that navigate restricted areas cleanly. Larger models can accommodate longer jaws for enhanced reach. Proper jaw sizing reduces post-cut trimming requirements and guarantees cleaner initial cuts.

Spring Mechanism Function

Spring tension revolutionizes your cutting workflow by automatically returning jaws to the open position after each cut. This mechanism eliminates manual reopening between cuts, markedly increasing your cutting speed and reducing hand fatigue during extended modeling sessions.

Different spring designs offer varying tension levels that directly impact performance. Light tension requires minimal force to close but may lack cutting power for thicker sprues. Heavy tension provides stronger cutting force but demands more finger pressure. I recommend medium tension springs that balance cutting power with comfortable operation.

The spring mechanism enhances precision control by preventing you from applying excessive force that could damage delicate parts. Quality springs maintain consistent tension over thousands of cuts, ensuring reliable performance throughout your cutter’s lifespan.

Price Value Comparison

Quality springs justify their cost through improved workflow efficiency, but price shouldn’t be your only consideration when selecting sprue cutters. I recommend evaluating cutters within the $10 to $30 range based on materials and design features. Well-reviewed models typically provide superior durability and cutting performance, offering better long-term value than cheaper alternatives requiring frequent replacement.

Customer feedback and ratings reveal effectiveness patterns that help gauge overall worth. High ratings often correlate with consistent performance over extended use periods. Specialized cutters commanding premium prices may justify their cost through advanced engineering or ergonomic design features that benefit serious hobbyists.

I always check warranty options, as extended coverage protects your investment against manufacturing defects or premature wear. A quality cutter with solid warranty support delivers measurable value through reliable service life.

On a final note

Selecting the right sprue cutters transforms your modeling experience from frustrating to precise. I’ve tested these nine cutters across various plastic types and thicknesses. The Hakko CHP-170 delivers professional-grade performance for serious builders, while the Tamiya models offer reliable Japanese engineering. Budget-conscious modelers can’t go wrong with the IGAN-330 or BOENFU options. Consider your project types, hand size, and cutting frequency when choosing. Quality cutters reduce stress marks and eliminate the need for extensive cleanup work.