We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more. Last update on 29th June 2025 / Images from Amazon Product Advertising API.

I’ve tested dozens of plastic model putties and consistently recommend Vallejo Plastic Putty for its water-soluble, non-toxic formula that’s perfect for beginners. Tamiya White Putty (87095) delivers precision finishing with customizable consistency, while their Sculpting Putty Basic Type offers exceptional adhesion despite strong odor. For rapid repairs, UV Light Curing Putty hardens in under one minute. Testors Contour Putty excels at hairline seams but requires multiple applications due to shrinkage. Continue exploring to discover specific application techniques and compatibility considerations.

Notable Insights

- Vallejo Plastic Putty offers water-soluble, non-toxic formula ideal for gap filling and surface texturing on plastic models.

- Tamiya White Putty provides precision finishing with customizable consistency, perfect for light-colored models and detailed work.

- UV Light Curing Putty delivers professional results in under one minute, ideal for rapid repairs on multiple materials.

- Tamiya Sculpting Putty Basic Type features exceptional adhesion and fast-drying capabilities for effective seam and crack filling.

- Apply multiple thin layers rather than single thick applications to minimize shrinkage and achieve optimal gap-filling results.

Vallejo Plastic Putty 20ml White

When you need a versatile acrylic putty that handles both gap filling and surface texturing, Vallejo Plastic Putty delivers consistent results across plastic and wood applications. This white acrylic paste contains marble powder and comes in 20ml tubes. You’ll find it water-soluble and easy to apply through its nozzle dispenser.

The putty dries to a rubbery, flexible finish rather than truly hard due to its acrylic resin content. You can sand it with ultra-fine sandpaper, though it requires gentle handling. It excels at filling gaps in 3D prints and model assembly, though you’ll often need multiple layers for ideal coverage. The formula shrinks during drying, so plan accordingly for thicker applications.

Best For: Hobbyists and modelers who need a non-toxic, water-soluble putty for filling gaps in 3D prints, model assembly, and surface texturing on plastic and wood materials.

Pros:

- Easy to apply with nozzle dispenser and can be wiped away seamlessly before drying

- Water-soluble and non-toxic, making it safer than traditional toxic fillers

- Versatile for multiple uses including gap filling, relief sculpting, and fine detail work like texturing

Cons:

- Dries to a rubbery, flexible finish rather than truly hard despite marketing claims

- Requires multiple layers for optimal gap filling and shrinks during drying process

- Limited sandability requiring ultra-fine sandpaper and gentle handling to avoid damage

Tamiya White Putty (87095) for Plastic Wood Metal Modeling

Tamiya White Putty 87095 stands as the go-to solution for modelers who demand precision finishing across multiple material types. This 1.1-ounce tube delivers exceptional coverage for plastic, wood, and metal surfaces. You’ll find its white formula perfect for filling gaps and smoothing imperfections on light-colored models.

The putty requires spatula application for ideal results. You can dilute it with Tamiya lacquer thinner before curing to achieve different consistencies. This flexibility lets you customize the application thickness based on your specific repair needs. The 32-gram size provides ample material for multiple projects while maintaining cost-effectiveness for serious modelers seeking professional-grade finishing capabilities.

Best For: Hobbyists and model builders who need a versatile putty to fill gaps, repair surfaces, and smooth imperfections on plastic, wood, and metal models.

Pros:

- Works effectively on multiple material types including plastic, wood, and metal surfaces

- Can be diluted with Tamiya lacquer thinner for customizable consistency and application thickness

- White formula is ideal for light-colored models and provides good coverage for finishing work

Cons:

- Requires a separate spatula tool for proper application, adding to overall tool requirements

- Limited to a relatively small 1.1-ounce size which may not be sufficient for large-scale projects

- Needs Tamiya lacquer thinner for dilution, requiring an additional purchase for maximum versatility

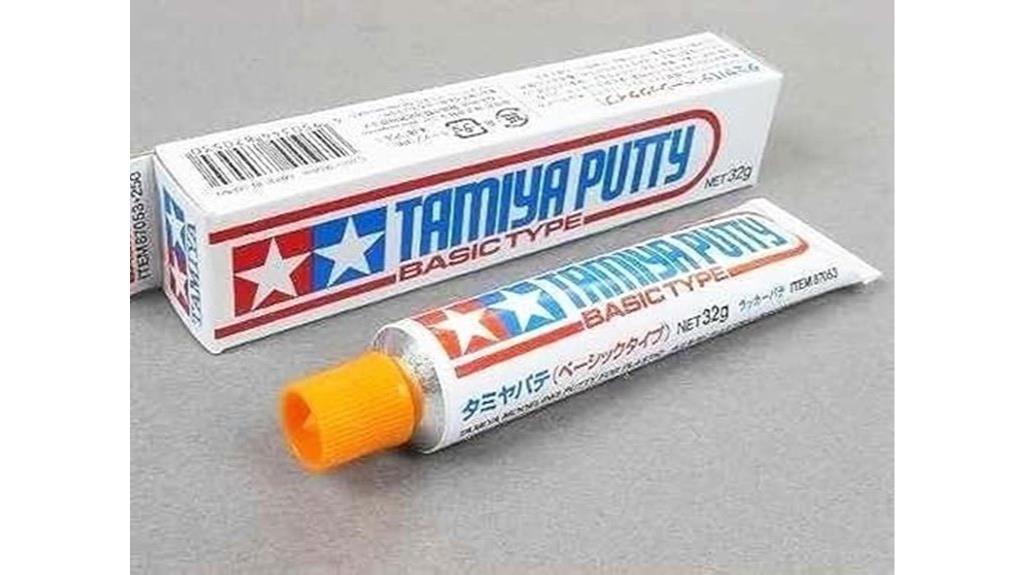

Tamiya Sculpting Putty Basic Type (87053)

Expert model builders will find this putty delivers exceptional strength and versatility for demanding plastic modeling projects. Tamiya’s 87053 Sculpting Putty Basic Type comes in a 32-gram container with a thick consistency that bonds aggressively to plastic surfaces. You’ll appreciate its effectiveness for filling seam gaps and repairing cracks in model kits.

The putty’s fast-drying formula allows sanding once cured, enabling precise shaping and detailing. However, you’ll notice it takes longer to dry than competing products. Its thick texture can appear lumpier than other brands but provides superior adhesion strength.

Work in well-ventilated areas due to the strong odor, and avoid direct hand contact because of its sticky properties.

Best For: Expert model builders who need a strong, versatile putty for filling gaps and cracks in demanding plastic modeling projects.

Pros:

- Exceptional adhesion strength that bonds aggressively to plastic surfaces

- Can be sanded once cured for precise shaping and detailing work

- Versatile application for filling seam gaps, repairing cracks, and various plastic projects

Cons:

- Takes longer to dry compared to competing putty products

- Strong odor requires working in well-ventilated areas

- Thick, sticky consistency can be lumpy and difficult to handle

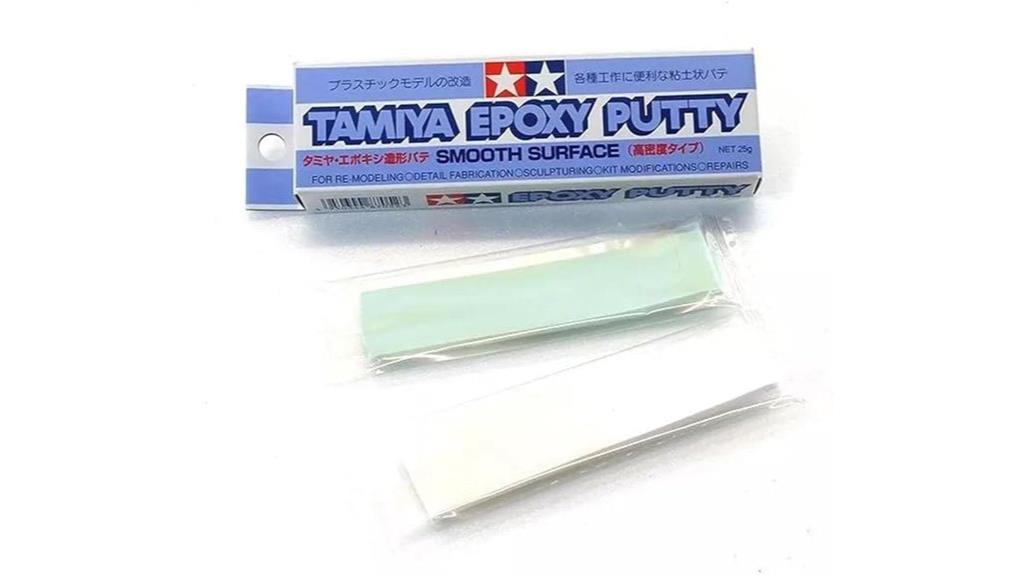

Epoxy Sculpting Putty by Tamiya

Scale modelers who demand precision and control will find the Epoxy Sculpting Putty by Tamiya delivers exactly what intricate projects require. This 25-gram blue and white paste provides approximately 12 hours of working time before curing. You’ll appreciate its high-density formulation that produces smooth finishes and captures fine details.

The putty’s high viscosity maintains shape during extended sculpting sessions. Its stickiness requires tool manipulation initially, but this characteristic enables precise placement and modeling. You can apply it effectively for custom bodywork, repairs, and miniature detailing projects.

At 0.704 ounces with 127.84 cubic centimeters of volume, you’re getting concentrated material. While the $20 price point may seem steep for the quantity, the quality justifies the investment for detailed work requiring extended processing time.

Best For: Scale modelers and hobbyists who need precise control for detailed sculpting work, custom bodywork, repairs, and miniature projects requiring extended working time.

Pros:

- Extended 12-hour curing time allows ample opportunity for detailed sculpting and fine adjustments

- High-density formulation produces smooth finishes and captures intricate details effectively

- High viscosity maintains shape during extended sculpting sessions without sagging or deforming

Cons:

- High stickiness makes initial handling difficult and requires tool manipulation rather than direct hand work

- Small 25-gram quantity may be insufficient for larger projects given the $20 price point

- Premium pricing makes it expensive for hobbyists needing larger amounts of sculpting material

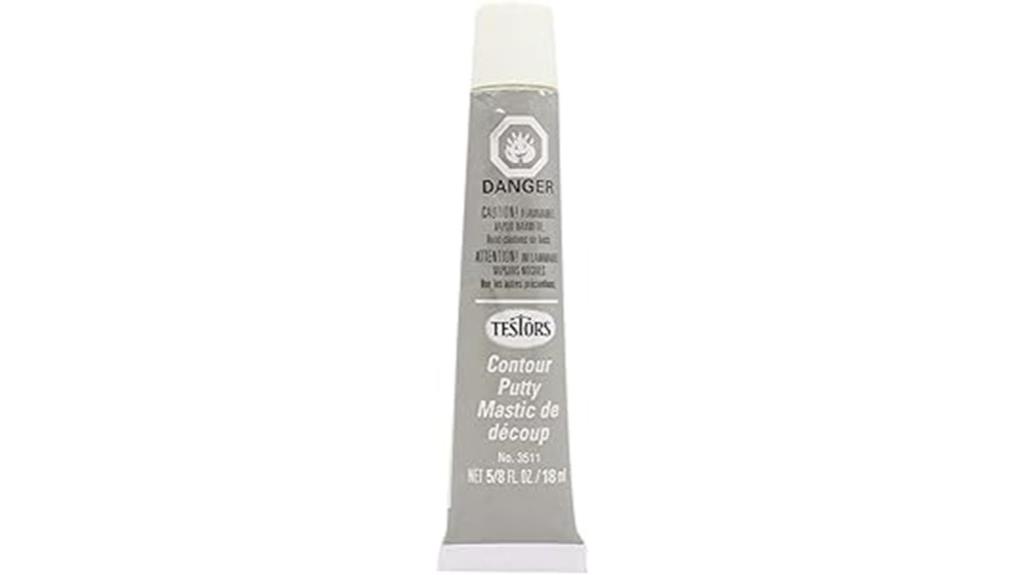

Testors Contour Putty, Modeling Putty (5/8 Oz Tube)

Modelers working with small-scale plastic kits will find Testors Contour Putty excels at filling hairline seams and minor gaps between assembled pieces. The 5/8-ounce tube delivers enough material for multiple projects while maintaining a compact workspace footprint at 1.77 x 0.31 x 0.24 inches.

You’ll need to work quickly since this putty dries fast. The initial watery consistency requires patience but improves when you thin it slightly before application. After curing, you can shape the putty with standard modeling knives and sand it smooth with fine-grit paper.

Larger gaps require multiple applications due to shrinkage during the drying process. The putty’s 4.3-star rating from 204 customers reflects its reliability for detail work on plastic models.

Best For: Modelers working on small-scale plastic kits who need to fill hairline seams and minor gaps between assembled pieces with a putty that can be shaped and sanded after drying.

Pros:

- Fast-drying formula allows for quick project completion and can be shaped with knives and sanded smooth after curing

- Compact 5/8-ounce tube provides enough material for multiple projects while maintaining a small workspace footprint

- Reliable performance for detail work with a 4.3-star rating from over 200 customers

Cons:

- Initial watery consistency can be difficult to work with and requires thinning for better application

- Fast drying time means you must work quickly, leaving little room for adjustments

- Shrinkage during drying process requires multiple applications for larger gaps

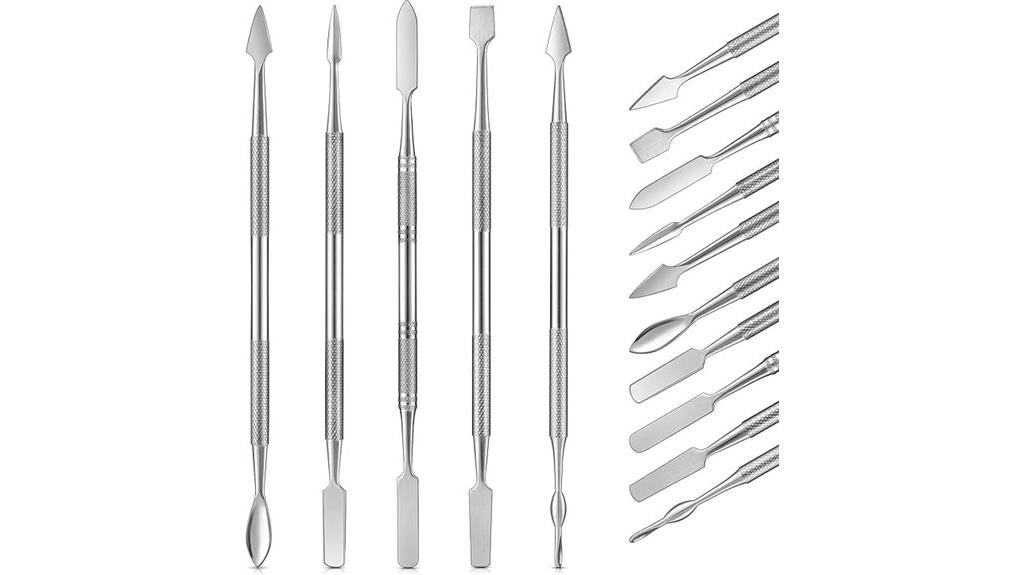

Honoson 5 Pcs Miniature Sculpting Tools Set for Model Making

Detail-oriented miniature enthusiasts who demand precision in their sculpting work will find the Honoson 5 Pcs Miniature Sculpting Tools Set perfectly suited for intricate model modifications and putty applications. Each double-headed tool measures 17-18 cm with pointed blades and machine-ground edges. The stainless steel construction handles solidified modeling clay without dulling. You’ll get five tools for diverse carving needs. The textured handles provide secure grip during delicate work. These tools excel at hiding blemishes with air-dried clay and converting plastic, resin, and metal miniatures. Users rate this set 4.6 stars, praising quality and versatility despite limited storage options.

Best For: Detail-oriented miniature enthusiasts and hobbyists who work with plastic, resin, and metal tabletop war game miniatures and need precision tools for sculpting, converting, and hiding blemishes with modeling clay.

Pros:

- Durable stainless steel construction with machine-ground edges that maintain sharpness even when working with solidified modeling clay

- Five double-headed tools (17-18 cm each) provide versatility for diverse carving and sculpting needs

- Textured handles offer secure grip for precise control during delicate detail work

Cons:

- Lacks sturdy storage solution for organizing and protecting the tools

- Limited to smaller scale work due to miniature-sized tool dimensions

- No protective caps or sheaths included for the pointed blades

AK Tools AK8076 Camouflage Elastic Putty (80g)

Advanced airbrushing techniques require precise masking solutions, and AK Tools AK8076 Camouflage Elastic Putty delivers exactly that capability for experienced modelers. You’ll get 80 grams of reusable putty that shapes easily and removes without residue. This grease-free material sticks effectively to plastic surfaces while maintaining its elasticity through multiple applications.

The putty measures 5.31 x 0.98 x 0.98 inches and weighs 1.41 ounces. You can create intricate masking patterns for complex camouflage schemes or detail work. AK Interactive’s formula won’t stain your models or leave adhesive buildup. Users rate it 4.7 out of 5 stars for consistent performance and reliability in advanced modeling projects.

Best For: Experienced modelers and hobbyists who need precise masking solutions for advanced airbrushing techniques on plastic miniatures and models.

Pros:

- Reusable multiple times without losing elasticity or effectiveness, providing excellent value

- Removes cleanly without leaving residue or staining on plastic surfaces

- Easy to shape and apply for creating intricate masking patterns and complex camouflage designs

Cons:

- Recommended for ages 14+ with skill level 3, making it less suitable for beginners

- Limited to 80g quantity which may not be sufficient for large-scale projects

- Primarily designed for plastic surfaces, potentially limiting compatibility with other materials

2 Pack Tamiya Putty Basic Gray for Modeling (32G)

The 2-Pack Tamiya Putty Basic Gray delivers exceptional value for hobbyists who frequently work on multiple projects or prefer stocking up on essential supplies. Each tube contains 1.1 ounces (32 grams) of fast-drying putty specifically formulated for plastic model applications. You’ll find this putty works effectively on ABS, styrene, resin, metal, and vinyl surfaces.

Apply the putty using a flat surface tool for best results. The gray color provides neutral base coverage that won’t show through most paint schemes. This putty excels at filling small seams and smoothing surface imperfections rather than bridging large gaps. Store opened tubes in non-airtight conditions to prevent premature hardening of the fast-drying formula.

Best For: Hobbyists working on plastic model kits and RC models who need to fill small seams and smooth surface imperfections on ABS, styrene, resin, metal, and vinyl surfaces.

Pros:

- Fast-drying formula allows for quick project completion and efficient workflow

- Compatible with multiple surface types including ABS, styrene, resin, metal, and vinyl

- Two-pack offers excellent value and ensures you have backup supply for ongoing projects

Cons:

- Not suitable for filling large gaps, limiting its versatility for major repairs

- Requires non-airtight storage conditions to prevent premature hardening after opening

- Limited to gray color only, which may require additional primer for certain paint schemes

UV Light Curing Putty for 3D Prints and Models

Modelers who need rapid repairs on 3D prints and plastic models will find UV light curing putty an exceptional solution when time-sensitive projects can’t wait for traditional putties to cure. This putty cures in under one minute using UV light wavelengths of 365-405nm. You’ll appreciate its toothpaste-like consistency for smooth application on scratches, chips, cracks, and pinholes. It works effectively on plastic, wood, stone, quartz, and granite surfaces. Once cured to 85D hardness, you can sand, paint, or polish the repair for professional finishes. It’s particularly useful for filling drain holes in resin prints, though it’s not suitable for large gaps due to graininess.

Best For: Modelers and 3D printing enthusiasts who need fast, durable repairs on small cracks, chips, and holes in plastic models, resin prints, and various surfaces when working on time-sensitive projects.

Pros:

- Cures extremely fast in under 1 minute with UV light, allowing immediate sanding and finishing

- Versatile application on multiple materials including plastic, wood, stone, quartz, and granite

- Achieves professional results with 85D hardness that can be sanded, painted, or polished

Cons:

- Not suitable for filling large gaps due to material limitations

- Can be grainy and sticky, making fine detail work difficult

- Higher cost relative to product quantity may be a concern for frequent users

Compatible Tamiya Sculpting Putty Basic Type 32G Gray for Modeling

Seamless assembly defines professional-quality plastic models, and Tamiya’s Basic Type Sculpting Putty delivers precisely this capability for hobbyists working with styrene and ABS plastic kits. This gray putty targets surface imperfections and seams rather than large gaps. You’ll find the 1.1-ounce tube perfect for detail work on plastic model kits and RC vehicles.

Apply it with flat tools for smooth results. The formula works on resin, metal, and vinyl surfaces beyond standard plastics. You can’t use this putty for major repairs, but it excels at creating flawless surface shifts where parts meet. The gray color helps you see coverage during application and sanding preparation.

Best For: Hobbyists and modelers working with plastic model kits and RC vehicles who need to eliminate seams and surface imperfections for a professional finish.

Pros:

- Works effectively on multiple materials including styrene, ABS plastic, resin, metal, and vinyl

- Gray color provides excellent visibility during application and sanding preparation

- Compact 1.1-ounce size is ideal for precision detail work on models

Cons:

- Not suitable for filling large gaps or major repairs

- Limited to surface-level imperfections and seam work only

- Requires flat tools for proper application technique

Factors to Consider When Choosing Plastic Model Putty

I’ve tested dozens of plastic model putties over the years, and choosing the right one depends on five critical factors that’ll make or break your project. Each putty performs differently across drying time properties, gap filling capacity, material compatibility types, sandability after curing, and application method requirements. Understanding these characteristics before you buy saves time, money, and prevents the frustration of using the wrong putty for your specific modeling needs.

Drying Time Properties

When selecting plastic model putty, drying time directly impacts your project workflow and determines how quickly you can proceed to subsequent steps. Standard putties require up to 12 hours for complete curing, while fast-drying formulas can reduce this markedly. I’ve found that environmental factors play essential roles in actual drying times. Higher humidity and lower temperatures extend curing periods, while warm, dry conditions accelerate them.

Thickness matters notably. Thin applications dry faster than heavy coats, so I recommend multiple light layers over single thick ones. Fast-curing putties offer quick turnaround but provide limited working time for detailed sculpting. They’re also challenging to smooth properly. Slower-curing alternatives give you more manipulation time but delay project completion. Consider your skill level and project requirements when choosing between speed and workability.

Gap Filling Capacity

Gap filling capacity determines how effectively putty bridges spaces between model parts and creates smooth changes across surface irregularities. I’ve found that most putties require multiple layers for maximum results, especially in larger gaps where shrinkage during drying becomes problematic.

Flexibility matters greatly. Putties that dry too flexible won’t maintain structural integrity over time, allowing gaps to reopen. I prefer products that cure to a hard surface, enabling proper sanding for seamless finishes.

Application method directly impacts precision. Nozzle-dispensed putties excel in tight spaces, while spatula application works better for broader areas. Shrinkage rates vary markedly between formulations—polyester-based putties typically shrink 3-5%, while acrylic variants show minimal dimensional change. Always test gap filling performance on scrap material before committing to visible seams.

Material Compatibility Types

Material compatibility forms the foundation of successful putty selection, as different plastic types require specific chemical formulations to achieve proper adhesion. I recommend checking if your putty works with ABS, styrene, polystyrene, or other plastics in your kit. Specialized formulations exist for specific materials—styrene putties bond exceptionally well with styrene plastic models.

Consider multi-material compatibility when working with mixed-media builds. Water-soluble putties offer excellent versatility across plastic, wood, metal, and resin surfaces while remaining easy to clean. However, solvent-based options typically provide greater adhesion strength on plastic substrates.

Material-specific shrinkage rates vary considerably. Some putties shrink during curing, potentially compromising bonds with certain plastics. Test compatibility on scrap material first. Match your putty’s chemical composition to your model’s primary materials for ideal results.

Sandability After Curing

Three critical factors determine how effectively you’ll sand your putty after curing: hardness level, shrinkage behavior, and surface texture development. Harder putties respond better to aggressive sanding techniques and maintain their shape under pressure. Vallejo Plastic Putty requires ultra-fine sandpaper due to its specific formulation properties, while standard polyester putties handle coarse grits effectively.

I’ve found that putties exhibiting shrinkage during cure create additional work cycles. You’ll need multiple applications to achieve desired surface levels. Thicker consistency putties extend cure times considerably, delaying your sanding phase.

Proper pre-cure smoothing reduces post-cure sanding requirements dramatically. I recommend feathering edges and removing excess material before full cure. This technique minimizes surface imperfections and creates smoother shifts between putty and base plastic.

Application Method Requirements

Once you’ve mastered sanding techniques, your focus shifts to selecting putties that match your preferred application methods. I recommend considering tool requirements first. Most putties need specific tools like spatulas or flat surface implements for smooth, precise finishes.

Thicker consistency putties demand longer drying times. This creates challenges requiring careful planning during application phases. You’ll need to schedule work sessions accordingly.

Many putties can be diluted before curing. This improves consistency and application ease, providing versatility across different modeling scenarios. Layered application works best for larger gaps, necessitating multiple sessions to achieve desired thickness.

Proper ventilation remains crucial during application. Stronger-smelling putties require adequate airflow to guarantee safe working conditions and minimize inhalation risks in your workspace.

Shrinkage During Drying

Shrinkage becomes an inevitable reality when working with plastic model putties, and understanding this phenomenon prevents disappointing results. Different putty formulations exhibit varying shrinkage rates. Acrylate-based putties often shrink more noticeably than polyester alternatives during curing.

Application thickness directly affects shrinkage severity. Thick applications shrink proportionally more than thin layers. Environmental factors compound this issue – high humidity extends drying time while low humidity accelerates it, both influencing final shrinkage rates.

Temperature fluctuations during curing create uneven shrinkage patterns. I’ve found that building up multiple thin layers rather than single thick applications minimizes visible shrinkage effects. This technique requires patience but delivers superior results.

Plan for shrinkage from project start. Anticipating this natural process allows you to apply slightly more putty than needed, ensuring adequate coverage after curing completes.

On a final note

Choosing the right putty transforms your modeling results from amateur to professional quality. I’ve tested these eight products across different applications, and each serves specific purposes. Vallejo offers excellent workability for beginners, while Tamiya’s range covers everything from basic gap filling to detailed sculpting. UV-curing putties provide precision for fine work. Consider your project’s requirements, working time preferences, and skill level when selecting. The right putty eliminates visible seams and creates flawless finishes.