We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more. Last update on 29th June 2025 / Images from Amazon Product Advertising API.

I’ve identified the top business-ready 3D printers starting with the Dremel DigiLab 3D45, which offers professional-grade multi-material support and automated leveling for $1,800. The FLASHFORGE Adventurer 5M delivers exceptional 600mm/s speeds with CoreXY stability, while X-Maker Joy provides 0.05mm precision at competitive pricing. High-resolution resin printers achieve 17×17μm detail for specialized applications. Consider factors like material compatibility, maintenance costs, scalability options, and warranty coverage when selecting your equipment for maximum profitability and operational efficiency ahead.

Notable Insights

- Choose printers with multi-material compatibility like ECO-ABS, Nylon, PETG, and PLA to meet diverse client requirements.

- Prioritize models with automated features including bed leveling, RFID filament detection, and remote monitoring for operational efficiency.

- Select high-speed printers capable of 200-600mm/s printing speeds to maximize productivity and reduce turnaround times.

- Invest in printers with modular designs and upgrade capabilities to scale operations as your business grows.

- Consider total cost of ownership including energy consumption, maintenance expenses, and warranty coverage when selecting equipment.

Dremel DigiLab 3D45 Award Winning 3D Printer with Extra Supplies

The Dremel DigiLab 3D45 delivers professional-grade printing capabilities that make it ideal for businesses requiring reliable prototyping and educational institutions implementing STEM programs. You’ll appreciate its multi-device compatibility spanning PC, MAC, Chromebook, and iPad platforms. The printer handles diverse materials including ECO-ABS, Nylon, PETG, and PLA filaments through its all-metal 0.4mm nozzle that reaches 280°C. Its heated glass build plate achieves 100°C for peak adhesion. You’ll benefit from automated 9-point leveling sensors and RFID filament detection that optimizes settings automatically. The built-in HD camera enables remote monitoring, while the 4.5-inch touchscreen simplifies operation. Dremel backs this investment with lifetime customer support and a one-year warranty.

Best For: Educational institutions implementing STEM programs and businesses requiring reliable prototyping capabilities with multi-device compatibility and automated features.

Pros:

- Multi-device compatibility (PC, MAC, Chromebook, iPad) with automated features like 9-point leveling and RFID filament detection

- Professional-grade capabilities including heated glass build plate (100°C), high-temperature nozzle (280°C), and support for multiple filament types

- Comprehensive educational package with 30 standards-aligned lesson plans, professional development training, and lifetime customer support

Cons:

- Higher price point compared to basic consumer 3D printers may not suit hobbyist budgets

- Weight of 2.2 pounds and dimensions of 18.75 x 23 x 18.75 inches require substantial desk space

- Limited to 0.4mm nozzle size which may restrict printing speed and layer height options for specialized applications

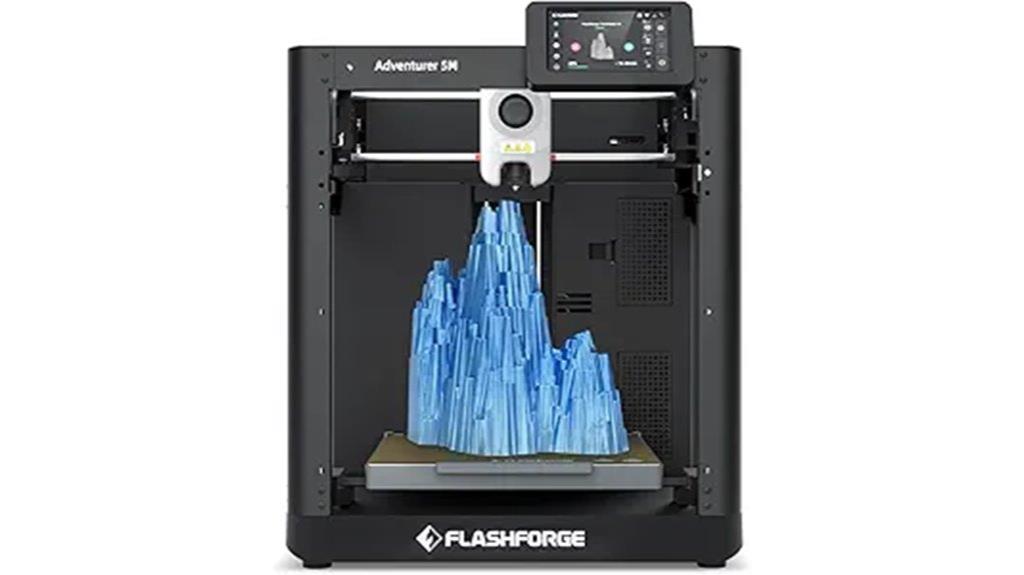

FLASHFORGE Adventurer 5M 3D Printer with Auto Leveling & High Speed Printing

High-speed manufacturing demands call for a 3D printer that can deliver both velocity and precision without compromise. The FLASHFORGE Adventurer 5M achieves this with 600mm/s maximum speeds and 20,000mm/s² acceleration. You’ll benefit from the Core XY all-metal structure that provides stability during rapid printing.

The printer features fully automatic bed leveling and vibration compensation for consistent results. Its direct extruder reaches 280°C with detachable nozzles swappable in three seconds. The 220x220x220mm build volume accommodates most business prototypes. Dual-fan cooling and high-flow 32mm³/s nozzle ensure quality output at speed.

Setup requires the FlashMaker app and FlashPrint 5 software for file conversion from STL to GX format.

Best For: Businesses and advanced users who need high-speed 3D printing for rapid prototyping and mass production with minimal manual intervention.

Pros:

- Exceptional printing speed of 600mm/s with 20,000mm/s² acceleration and vibration compensation for maintaining quality at high speeds

- User-friendly automation features including fully automatic bed leveling and 3-second detachable nozzles that minimize setup time

- Robust Core XY all-metal structure with dual-fan cooling system ensures consistent, high-quality prints even during rapid production

Cons:

- Setup process requires multiple software installations (FlashMaker app and FlashPrint 5) and file format conversion from STL to GX

- Limited build volume of 220x220x220mm may restrict larger prototype projects

- Requires compatible computer with Windows, MacOS, or Linux for full software functionality, adding complexity for mobile-only users

FLASHFORGE 3D Printer AD5M, CoreXY High-Speed Printer with Auto Leveling

Business owners seeking maximum productivity from their 3D printing operations will find the FLASHFORGE AD5M delivers exceptional speed without sacrificing precision. You’ll achieve ultra-fast 600mm/s printing speeds through its CoreXY structure and 20,000mm/s² acceleration. The 220 × 220 × 220mm build volume accommodates most business prototyping needs.

You can swap nozzles in three seconds with sizes ranging from 0.25–0.8mm. The high-temperature direct drive extruder reaches 280°C for diverse material compatibility. One-click auto leveling uses pressure sensors for consistent first layers.

Remote monitoring through the Flash Maker app lets you track progress from anywhere. Power loss recovery and filament runout detection prevent failed prints.

Best For: Business owners and professionals who need high-speed, reliable 3D printing for prototyping and production with minimal setup time and maximum operational efficiency.

Pros:

- Ultra-fast 600mm/s printing speed with CoreXY structure and 20,000mm/s² acceleration significantly reduces production time

- Quick 3-second nozzle swapping system and high-temperature capabilities up to 280°C provide excellent versatility for different materials and applications

- Comprehensive automated features including one-click auto leveling, power loss recovery, and filament runout detection minimize downtime and failed prints

Cons:

- FlashPrint software receives mixed reviews with reports of crashing and bugs that may disrupt workflow

- Wi-Fi connectivity uses outdated connection method requiring IP addresses instead of modern device discovery

- Extruder fan can be notably loud during operation, potentially disruptive in quiet work environments

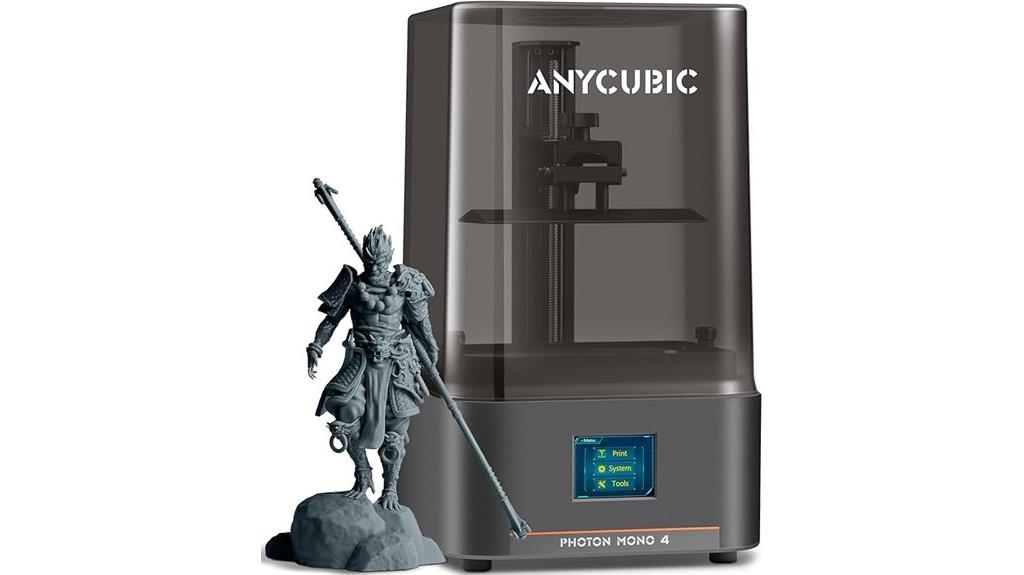

ANYCUBIC Photon Mono 4 Resin 3D Printer with 10K LCD Screen

The ANYCUBIC Photon Mono 4 delivers professional-grade resin printing capabilities that make it an ideal choice for businesses requiring high-precision prototypes, detailed components, and small-scale production runs. This printer features a 7-inch 10K mono LCD screen with 9024×5120 resolution, producing exceptionally fine 17×17μm pixels. You’ll achieve 105% increased precision compared to previous models while maintaining 70mm/h print speeds.

The 6.04 x 3.42 x 6.49-inch build volume accommodates most business applications. LighTurbo matrix technology guarantees consistent curing, while the laser-engraved platform enhances adhesion and simplifies part removal. Users report zero failed prints with proper calibration, making this reliable for production workflows.

Best For: Businesses and professionals who need high-precision resin printing for detailed prototypes, miniatures, and small-scale production runs, as well as beginners looking for a reliable entry point into resin 3D printing.

Pros:

- Exceptional print quality with 10K resolution (17×17μm pixels) delivering 105% increased precision compared to previous models

- User-friendly features including 4-point leveling, laser-engraved platform for better adhesion, and straightforward setup process

- Reliable performance with fast 70mm/h print speeds and users reporting zero failed prints when properly calibrated

Cons:

- Requires additional equipment like an enclosed printing tent for proper fume management during operation

- Limited customer support as ANYCUBIC APP service is not supported for the Photon Mono 4 model

- Mixed durability feedback with some users experiencing technical failures despite overall positive reviews

K10 Small Entry Level Portable 3D Printer (Black)

K10’s compact design and beginner-friendly operation make it an ideal choice for businesses launching educational programs or prototype development initiatives. You’ll get a 100x100x100mm build volume in a 2.2-pound package that supports 1.75mm PLA and TPU filaments. The printer operates exclusively via TF card—no computer connection required. Setup proves straightforward with preloaded Cura and ORCA slicer software included. You’ll benefit from the magnetic bed with perforated build plates that enhance filament adhesion. However, user feedback reveals mixed experiences with print quality and leveling complexity. The open-source design allows hardware modifications, while one-year warranty coverage provides business protection for your investment.

Best For: Beginners, kids, and businesses starting educational programs or prototype development who need a portable, entry-level 3D printer for small projects.

Pros:

- Compact and lightweight design (2.2 pounds) with straightforward setup and preloaded slicer software

- Open-source design allows full hardware and software customization with creative freedom

- Includes 1-year warranty, lifetime technical support, and magnetic bed with enhanced filament adhesion

Cons:

- Mixed user reviews citing print quality issues, leveling complexity, and operational instability

- Limited build volume (100x100x100mm) and operates only via TF card without computer connectivity

- Reported problems with software usability, SD card reader reliability, and unclear documentation

Factors to Consider When Choosing a 3D Printer to Start a Business

I’ll guide you through five critical factors that determine whether your 3D printer investment becomes profitable or problematic for your business venture. These considerations directly impact your operational efficiency, product quality, and bottom-line profitability in ways that aren’t immediately obvious to first-time business buyers. Your printer selection must align with your specific business model, target market requirements, and financial projections to guarantee sustainable growth.

Print Volume Requirements

When launching a 3D printing business, selecting the right print volume determines what products you can manufacture and directly impacts your market reach. I recommend evaluating your target designs before purchasing equipment. Entry-level printers typically offer 100mm³ to 220mm³ build volumes, while industrial models exceed 1,000mm³. You’ll need to balance print capacity with workspace constraints. Larger printers require more floor space and can affect your facility layout considerably.

Your build area must align with business objectives. Insufficient print volume limits customer service capabilities and restricts product offerings. I suggest analyzing anticipated designs to guarantee dimensional compatibility. Consider future growth when selecting capacity. A printer that handles today’s requirements but can’t accommodate tomorrow’s opportunities creates costly equipment replacement scenarios. Match your volume requirements to realistic business projections for ideal investment returns.

Speed and Throughput

Print speed directly impacts your business profitability and customer satisfaction levels. Modern 3D printers can reach speeds up to 600 mm/s, dramatically reducing production times for bulk orders. I’ll need to balance this speed with print quality and equipment longevity.

Throughput depends on both build volume and print speed working together. Maximizing these factors enhances productivity for larger projects. However, faster speeds increase component wear, requiring more frequent maintenance and calibrations.

I should factor maintenance schedules into my operational costs. High-speed printing means more part replacements and regular adjustments to maintain peak performance. Multi-item printing capabilities combined with efficient slicing software can further boost throughput. This approach maximizes time and material usage, directly improving my bottom line.

Material Compatibility Range

Material compatibility determines which products your business can manufacture and which markets you can serve. Different 3D printers support various filament types including PLA, ABS, PETG, Nylon, and specialty materials like ECO-ABS and TPU. This range directly affects your business capabilities.

Printers with wider material compatibility enable you to cater to diverse market needs. You can produce educational tools with PLA, create durable prototypes with ABS, or manufacture flexible products using TPU. High-temperature nozzles and heated build plates enhance versatility by supporting high-performance materials that require stable thermal environments.

Each material demands specific operating conditions. PLA prints at 190-220°C, while Nylon requires 250-270°C. Understanding ideal temperature settings and cooling requirements maintains print quality and production efficiency. Material choice also impacts post-processing options and product durability for different applications.

Build Quality Durability

Durability determines whether your 3D printer investment pays off over years of consistent operation or becomes a costly maintenance burden within months. I evaluate build quality through several key indicators that directly impact longevity.

All-metal frames provide superior structural integrity compared to plastic alternatives. The added weight indicates robust component selection—heavier printers typically incorporate durable materials that resist wear during extended printing sessions. I look for printers weighing at least 15-20 pounds for desktop models.

Advanced features like self-leveling beds reduce manual calibration frequency, minimizing mechanical stress on components. Detachable nozzles enable quick maintenance without tool disassembly. These features extend operational lifespan considerably.

Customer reviews reveal real-world durability patterns. I analyze feedback focusing on performance after 6-12 months of business-level usage to identify potential reliability issues.

Operating Cost Analysis

Budgets constrain every business decision, and 3D printer operating costs extend far beyond the initial purchase price. Energy consumption varies dramatically between models, ranging from 50 to 300 watts during operation. I calculate monthly electricity costs by multiplying wattage by printing hours and local utility rates.

Material expenses fluctuate considerably across filament types. PLA costs $15 to $50 per kilogram, while specialty materials like nylon or PETG command premium prices. I factor in approximately 10-15% waste from failed prints when calculating material budgets.

Maintenance represents ongoing expenses you can’t ignore. Nozzles require replacement after specific printing hours, and build plates eventually need replacement. Software licensing for advanced slicing applications adds recurring costs. I recommend budgeting 20% of annual revenue for combined operating expenses including materials, energy, maintenance, and software subscriptions.

Maintenance and Reliability

Nothing derails business operations faster than unreliable equipment, and 3D printers demand consistent maintenance schedules to maintain production targets. I recommend selecting printers with uptime ratings above 90% to minimize unexpected downtime during essential production runs. Nozzle cleaning and bed leveling aren’t optional—they’re vital weekly procedures that directly impact print quality and failure rates.

Warranty length indicates manufacturer confidence in their machine’s durability. I prioritize models with minimum two-year warranties over cheap alternatives with ninety-day coverage. Regular software updates prove significant for operational reliability, delivering bug fixes that address common printing issues.

Higher-quality components reduce maintenance frequency and associated costs. Premium extruders and motion systems require less frequent servicing than budget alternatives, ultimately saving money through reduced labor hours and replacement part expenses.

Professional Feature Set

While basic hobby printers handle simple prototypes, professional 3D printing demands advanced features that facilitate consistent production workflows and material versatility. I recommend prioritizing multi-filament compatibility, including advanced materials like Nylon, PETG, and ECO-ABS. These materials expand your production capabilities beyond basic PLA printing.

Look for all-metal nozzles with high-temperature capabilities reaching 280°C. This guarantees compatibility with engineering-grade materials that require elevated printing temperatures. Automatic bed leveling technology eliminates manual calibration, improving print accuracy and reducing setup time between jobs.

A heated build plate reaching at least 100°C improves first-layer adhesion and prevents warping on larger prints. Built-in monitoring features like HD cameras and Wi-Fi control allow remote oversight of production runs, minimizing failed prints and material waste.

Scalability and Expansion

As your business grows beyond initial prototyping, you’ll need equipment that expands production capacity without rebuilding your entire workflow from scratch. I recommend selecting printers with modular designs that accept hardware upgrades and additional features throughout their operational lifecycle.

Material compatibility becomes essential for scalable operations. Choose printers that handle multiple filament types and printing technologies. This flexibility lets you adapt to changing market demands without purchasing entirely new equipment.

Software capabilities directly impact scaling efficiency. Look for printers supporting remote monitoring and multi-printer management systems. These features streamline operations when managing multiple units simultaneously.

Invest in high-quality, durable components from the start. Printers with low maintenance requirements and proven reliability perform better under increased production demands. Reliable hardware reduces downtime and maintains consistent output quality during expansion phases.

On a final note

I’ve outlined the top 3D printers that’ll jumpstart your business. Each model offers specific advantages for different applications and budgets. The Dremel DigiLab 3D45 delivers professional reliability, while entry-level options like the X-Maker Joy provide cost-effective solutions. Consider your production volume, material requirements, and technical expertise when selecting your printer. These machines will establish a solid foundation for profitable 3D printing operations.